2 / 20

0006081531_201203

ENGLISH

FOREWORD

These warning notes are aimed at ensuring the safe use of the compo-

nents of heating systems for civil use and the production of hot water.

They indicate how to act to avoid the essential safety of the components

being compromised by incorrect or erroneous installation and by improper

or unreasonable use. The warning notes provided in this guide also seek

to make the consumer more aware of safety problems in general, using

necessarily technical but easily understood language. The manufacturer

is not liable contractually or extra contractually for any damage caused

by errors in installation and in use, or where there has been any failure to

follow the manufacturer’s instructions.

GENERAL WARNING NOTES

• The instruction booklet is an integral and essential part of the product

and must be given to the user. Carefully read the warnings in the bo-

oklet as they contain important information regarding safe installation,

use and maintenance. Keep the booklet to hand for consultation when

needed.

• Equipment must be installed in accordance with current regulations,

with the manufacturer’s instructions and by qualifi ed technicians. By

the term ‘qualifi ed technicians’ is meant persons that are competent in

the fi eld of heating components for civil use and for the production of

hot water and, in particular, assistance centres authorised by the manu-

facturer. Incorrect installation may cause damage or injury to persons,

animals or things. The manufacturer will not in such cases be liable.

• After removing all the packaging make sure the contents are complete

and intact. If in doubt do not use the equipment and return it to the

supplier. The packaging materials (wooden crates, nails, staples, plastic

bags, expanded polystyrene, etc.) must not be left within reach of chil-

dren as they may be dangerous to them. They should also be collected

and disposed on in suitably prepared places so that they do no pollute

the environment.

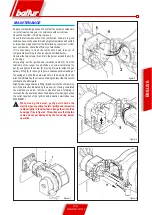

• Before carrying out any cleaning or maintenance, switch off the equi-

pment at the mains supply, using the system’s switch or shut-off sy-

stems.

• If there is any fault or if the equipment is not working properly, de-ac-

tivate the equipment and do not attempt to repair it or tamper with it

directly. In such case get in touch with only qualifi ed technicians. Any

product repairs must only be carried out by BALTUR authorised assi-

stance centres using only original spare parts. Failure to act as above

may jeopardise the safety of the equipment. To ensure the effi ciency

and correct working of the equipment, it is essential to have periodic

maintenance carried out by qualifi ed technicians following the manufac-

turer’s instructions.

• If the equipment is sold or transferred to another owner or if the owner

moves and leaves the equipment, make sure that the booklet always

goes with the equipment so it can be consulted by the new owner and/

or installer.

• For all equipment with optionals or kits (including electrical), only origi-

nal accessories must be used.

I

WARNING NOTES FOR THE USER HOW TO USE THE BURNER SAFELY

BURNERS

• This equipment must be used only for its expressly stated use: applied

to boilers, hot air boilers, ovens or other similar equipment and not

exposed to atmospheric agents. Any other use must be regarded as

improper use and hence dangerous.

• The burner must be installed in a suitable room that has ventilation in

accordance with current regulations and in any case suffi cient to ensure

correct combustion

• Do not obstruct or reduce the size of the burner’ air intake grills or the

ventilation openings for the room where a burner or a boiler is installed

or dangerous mixtures of toxic and explosive gases may form.

• Before connecting the burner check that the details on the plate corre-

spond to those of the utility supplies (electricity, gas, light oil or other

fuel).

• Do not touch hot parts of the burner. These, normally in the areas near

to the fl ame and any fuel pre-heating system, become hot when the

equipment is working and stay hot for some time after the burner has

stopped.

• If it is decided not to use the burner any more, the following actions must

be performed by qualifi ed technicians:

a) Switch off the electrical supply by disconnecting the power cable from

the master switch.

b) Cut off the fuel supply using the shut-off valve and remove the control

wheels from their position.

c) Render harmless any potentially dangerous parts.

Special warning notes

• Check that the person who carried out the installation of the burner fi xed

it securely to the heat generator so that the fl ame is generated inside

the combustion chamber of the generator itself.

• Before starting up the burner, and at least once a year, have qualifi ed

technicians perform the following operations:

a) Set the burner fuel capacity to the power required by the heat ge-

nerator.

b) Adjust the combustion air fl ow to obtain combustion yield of at least

the minimum set by current regulations.

c) Carry out a check on combustion to ensure the production of no-

xious or polluting unburnt gases does not exceed limits permitted

by current regulations.

d) Check the adjustment and safety devices are working properly.

e) Check the effi ciency of the combustion products exhaust duct.

f) Check at the end of the adjustments that all the adjustment devices

mechanical securing systems are properly tightened.

g) Make sure that the use and maintenance manual for the burner is

in the boiler room.

• If the burner repeatedly stops in lock-out, do not keep trying to manually

reset but call a qualifi ed technicians to sort out the problem.

• The running and maintenance of the equipment must only be carried

out by qualifi ed technicians, in compliance with current regulations.

Summary of Contents for TBG 85 ME

Page 2: ......

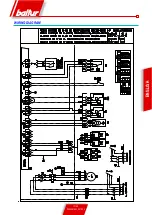

Page 19: ...17 20 0006081531_201203 ENGLISH WIRING DIAGRAM...

Page 20: ...18 20 0006081531_201203 ENGLISH START FOR RECORDER MINIMUM IONISATION CURRENT 1 5 A...

Page 39: ...17 20 0006081531_201203 ESPA OL ESQUEMA EL CTRICO...

Page 40: ...18 20 0006081531_201203 ESPA OL ARRANQUE PARA REGISTRADOR CORRENTE M NIMA DE IONIZACI N 1 5 A...

Page 59: ...17 20 0006081531_201203 FRAN AIS SCHEMA ELECTRIQUE...

Page 60: ...18 20 0006081531_201203 FRAN AIS MARCHE POUR ENREGISTREUR COURANT D IONISATION MINIMUM 1 5 A...

Page 79: ...17 20 0006081531_201203 T RK E ELEKTR K EMASI...

Page 80: ...18 20 0006081531_201203 T RK E REG LAT R N BA LATMA M N MUM YON ZASYON AKIMI 1 5 A...

Page 84: ...2 20 0006081531_201203 PYCCK BALTUR a b c a b c d e f g...

Page 85: ...3 20 0006081531_201203 PYCCK 2 RC a b c d e a b a b c d...

Page 89: ...7 20 0006081531_201203 PYCCK A 5 6 B 3 2 C 4 1 7 8 8a 9 DN65 DN80 A B 10 C 11...

Page 90: ...8 20 0006081531_201203 N 0002910950n2 PYCCK EN676 1 2 3 4 5 6 7 8 9 10 11 12 13 14...

Page 94: ...12 20 0006081531_201203 ioniz_BT3xx PYCCK 1 4 A 13 14 15...

Page 99: ...17 20 0006081531_201203 PYCCK...

Page 100: ...18 20 0006081531_201203 PYCCK 1 5 A...

Page 101: ...19 20 0006081531_201203 PYCCK 0 4 20 A...

Page 104: ...2 20 0006081531_201203 a b c a b c d e f g I...

Page 105: ...3 20 0006081531_201203 2 RC a b c d e a b a b c d I...

Page 109: ...7 20 0006081531_201203 5 6 2 3 7 4 1 8 8A 9 DN65 DN80 10 11...

Page 110: ...8 20 0006081531_201203 N 0002910950n2 EN676 1 2 3 4 5 6 7 8 9 10 11 12 13 14...

Page 113: ...11 20 0006081531_201203 display lamtec BT3xx 3 4 1 2 5 1 2 3 4 5 O BT3xx BT 3xx 200 CO...

Page 114: ...12 20 0006081531_201203 ioniz_BT3xx 1 4 A...

Page 117: ...15 20 0006081531_201203 figura 1 figura 2 figura 4 figura 3 2 2 1 3 4 5 8 6 8 9 0002934691 7 2...

Page 119: ...17 20 0006081531_201203...

Page 120: ...18 20 0006081531_201203 1 5 A...

Page 121: ...19 20 0006081531_201203 0 4 20 mA...

Page 123: ......