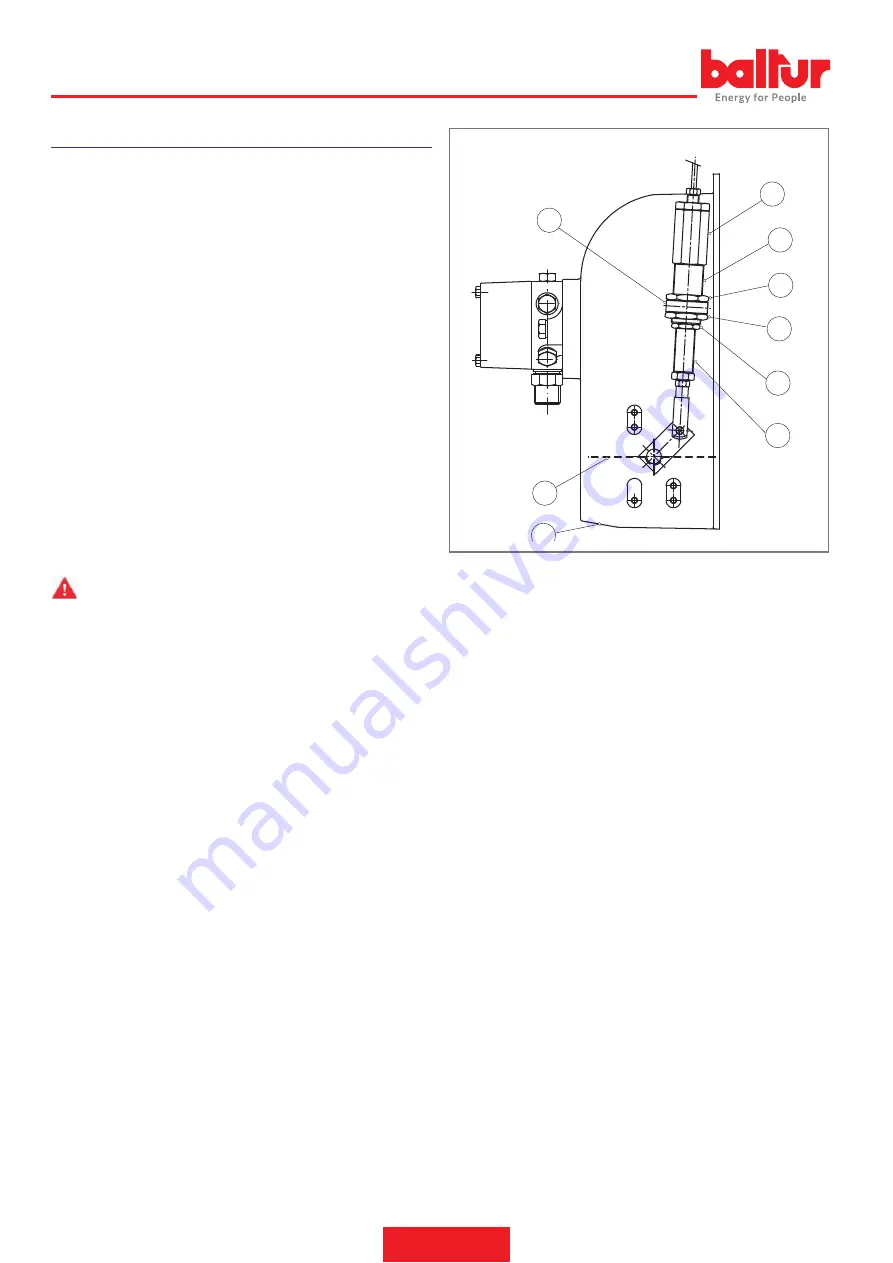

OSCILLATING JACK

ADJUSTMENT OF FIRST STAGE AIR DUMPER POSITION

•

To increase the flow rate, turn ring nut (3) anticlockwise using

the counter wrench on the body (1) of the jack to avoid putting

excessive stress on the eyelet pin (9).

•

This operation lowers the body (1) and favours the opening of the

first stage air damper (7).

•

To decrease the air flow rate, turn ring nut (4) clockwise, using

always the counter-wrench on the body of the jack.

•

In this case, the body (1) move upwards and favours air damper

closing (7).

•

Once the first stage air regulation is complete, lock the two ring

nuts (4) and (5).

ADJUSTMENT OF SECOND STAGE AIR DUMPER POSI-

TION

•

Loosen lock nut (6).

•

To increase second stage flow rate, undo the screw (5) so as to

lengthen the hydraulic piston stroke. Perform the operation in the

reverse order to reduce it.

•

After second stage air flow adjustment is completed, tighten nut

(6).

DANGER / ATTENTION

To avoid damaging the eyelet (9), carry out all the adjustment

operations with wrench and counter-wrench.

0002935420

9

1

2

3

4

6

5

7

8

30 / 44

0006081053_202301

ENGLISH

Summary of Contents for TBL 360P

Page 2: ......

Page 42: ...SCHEMI ELETTRICI TBL 85 105 130 160 210 260 P DACA 40 44 0006081053_202301 ITALIANO...

Page 43: ...TBL 85 105 130 160 210 260 P 41 44 0006081053_202301 ITALIANO...

Page 44: ...TBL 360 P DACA 42 44 0006081053_202301 ITALIANO...

Page 45: ...TBL 360 P 43 44 0006081053_202301 ITALIANO...

Page 86: ...WIRING DIAGRAMS TBL 85 105 130 160 210 260 P DACA 40 44 0006081053_202301 ENGLISH...

Page 87: ...TBL 85 105 130 160 210 260 P 41 44 0006081053_202301 ENGLISH...

Page 88: ...TBL 360 P DACA 42 44 0006081053_202301 ENGLISH...

Page 89: ...TBL 360 P 43 44 0006081053_202301 ENGLISH...

Page 91: ......