29 / 36

0006081428_201406

ENGLISH

SPECIFICATIONS FOR PROPANE

USE

•

Operating costs approximate assessment

- 1 m

3

of liquid gas in gaseous phase has a lower calorific power,

of about 22,000 kcal.

- To obtain 1 m

3

of gas we need about 2 Kg or about 4 litres

of liquid gas.

This reveals that the use of liquid gas (L.P.G.) yields approximately

the following equivalence: 22,000 kcal = 1 m

3

(in gaseous phase) =

2 kg of L.P.G. (liquid) = 4 l L.P.G. (liquid) from which the operating

cost can be assessed.

•

Safety provisions

Liquid propane gas (L.P.G.) in the gaseous form has a greater

specific weight than air (specific weight relative to air = 1.56 for

propane), which means it does not disperse in air like natural gas,

which has a lower specific weight than air (specific weight of natural

gas relative to air = 0.60), but precipitates and spreads out at ground

level (as if it were a liquid). Therefore, the Italian Ministry of the

Interior set limits on the use of liquid propane gas in memorandum

no. 412/4183 dated February 6 1975, of which we sum up the most

important concepts below.

- Liquefied petroleum gas (L.P.G.) burners and/or boilers may

be used only in premises located above ground level and

certified toward free spaces. Installations using liquid gas are

not allowed in underground or semi-underground premises.

- Premises where liquid gas is used must have ventilation

openings which cannot be closed on their outside walls with

a surface area measuring at least 1/15 of the surface area of

the room, with a minimum of 0.5 m

2

. At least one third of the

entire area of these inlets must be located in the lower part

of the external wall, flush with the floor.

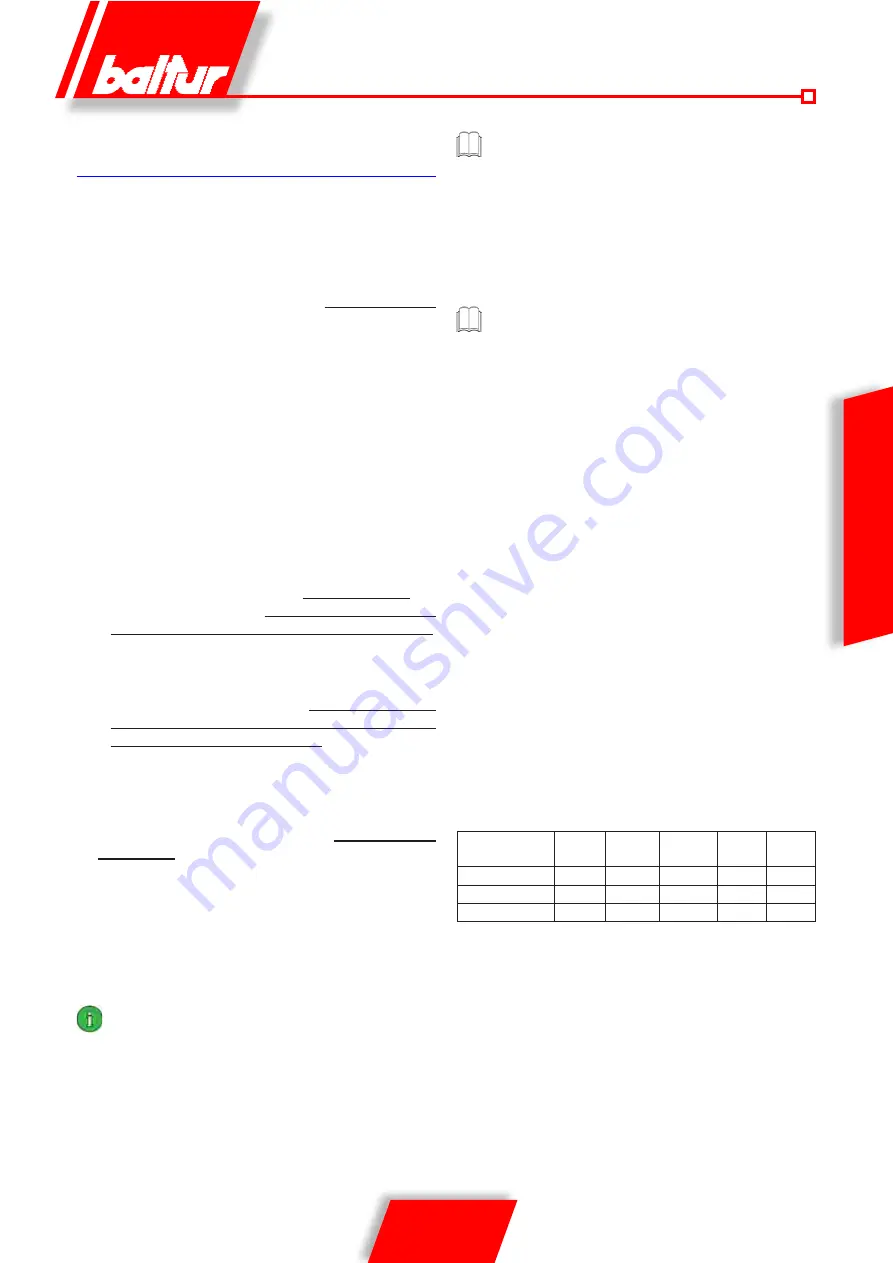

•

Measures to be taken for liquid gas system to ensure correct,

safe operation. Natural gasification, from a cylinder bank or

tank, can be used only for systems having low power. Gas

supply capacity on the basis of tank size and minimum outdoor

temperature are shown in the table below, as an approximate

indication only.

• Burner

The burner must be ordered specifically for use with liquid gas

(L.P.G.) so that it is equipped with gas valves of sufficient dimen-

sions to ensure correct ignition and gradual adjustment. The

valve sizing is foreseen for a supply pressure of approximately

300 mm W.C. You are recommended to check the burner gas

pressure using a water column manometer.

Minimum and maximum burner power (Kcal/h) is the one with

natural gas fuel. L.P.G. has greater heating capacity than

natural gas, which means that for a correct combustion it

requires a quantity of air proportionate to the heating power

produced.

TBML....MC and ME burners can also work with LPG without

adjusting the combustion head.

•

C o m b u s t i o n

c h e c k

To limit consumption and avoid serious trouble, adjust combus-

tion using the appropriate instruments. It is absolutely essential

to check that the percentage of carbon monoxide (CO) does not

exceed the maximum permitted value of 0,1 % (use a combustion

analyser or other similar instrument).

The warranty does not cover burners burning liquid gas

(L.P.G.) in installations in which these measures have not

been taken

.

Minimum

temperature

- 15 °C - 10 °C

- 5 °C

- 0 °C + 5 °C

990 l tank

1.6 Kg/h 2.5 Kg/h 3.5 Kg/h 8 Kg/h 10 Kg/h

3000 l tank

2.5 Kg/h 4.5 Kg/h 6.5 Kg/h 9 Kg/h 12 Kg/h

5000 l tank

4 Kg/h 6.5 Kg/h 11.5 Kg/h 16 Kg/h 21 Kg/h

Summary of Contents for TBML 160 PN

Page 2: ......

Page 36: ...34 36 0006081428_201406 ITALIANO SCHEMA ELETTRICO ...

Page 38: ...36 36 0006081428_201406 ITALIANO ...

Page 72: ...34 36 0006081428_201406 ENGLISH ELECTRIC DIAGRAM ...

Page 74: ...36 36 0006081428_201406 ENGLISH ...

Page 75: ......