ENGLISH

24 / 54

0006081544_201907

IGNITION AND ADJUSTMENT WITH

LIQUID FUEL

Before starting up, make sure that:

•

Make sure that the mains voltage corresponds to the

manufacturer's requirements and that all electrical connections

made at the installation site are effected properly as illustrated

in our wiring diagram.

•

Make sure that the combustion products may be freely vented

through the boiler and flue dampers.

•

Check that there is water in the boiler and that the gate valves

of the system are open.

•

Check that all the gate valves fitted on the fuel suction and

return pipes are open; the same applies to any other fuel shut-

off devices.

•

Adjust the air for the ignition flame:

It is recommended to first make the ignition with the liquid fuel as

the delivery is conditioned by the nozzle.

Then to regulate the gas operate the pressure regulator on the

gas train.

In burners with mechanical cam, after adjusting the gas, it is

necessary to re-check the liquid fuel calibration.

•

Connections to the supply line, to thermostats or pressure

switches, have been made according to the electrical diagram

of the equipment.

•

There is fuel oil in the tank and water in the boiler.

•

Make sure that the combustion head penetrates into the

furnace to the extent requested by the boiler manufacturer.

Check that the air closure device on the combustion head is

in the right position to guarantee a correct combustion, the air

passage between disk and head must be slightly reduced if a

relatively small amount of fuel is supplied. When the fuel supply

is abundant the air passage must be increased, see chapter

"COMBUSTION HEAD ADJUSTMENT”.

•

The right type of fuel has been selected.

•

Check that the nozzles fitted on the burner are suitable for the

boiler capacity. If necessary, replace them with suitable ones.

In no case should the quantity of fuel delivered exceed the

maximum amount required by the boiler and the maximum

amount allowed for the burner.

To start the burner proceed as follows:

DANGER / ATTENTION

Prevent operation of the second flame avoiding to connect

the 4-pin connector (2nd stage).

•

Adjust the air in the amount presumed to be necessary for the

1st stage ignition using the special cam of the air adjustment

servomotor (indicative value 15° - 20°)

• Turn on the main switch and the one on the control panel.

•

The programmer is activated and it starts carrying out the

predefined program activating the burner devices.The

equipment will start operation as described in the Chapter

“DESCRIPTION OF OPERATION”.

•

When the burner is operating in the 1st stage, adjust the amount

of air necessary to ensure an efficient combustion, see “AIR

ADJUSTMENT ON THE BURNER HEAD” and 0002938170 for

the gas- diesel 1st stage cam adjustment.

•

After adjusting the 1st stage air the burner stops disconnecting

the current from the main switch, the electric circuit commanding

the second stage activation closes connecting the 4-pole

connector according to the wiring diagram.

•

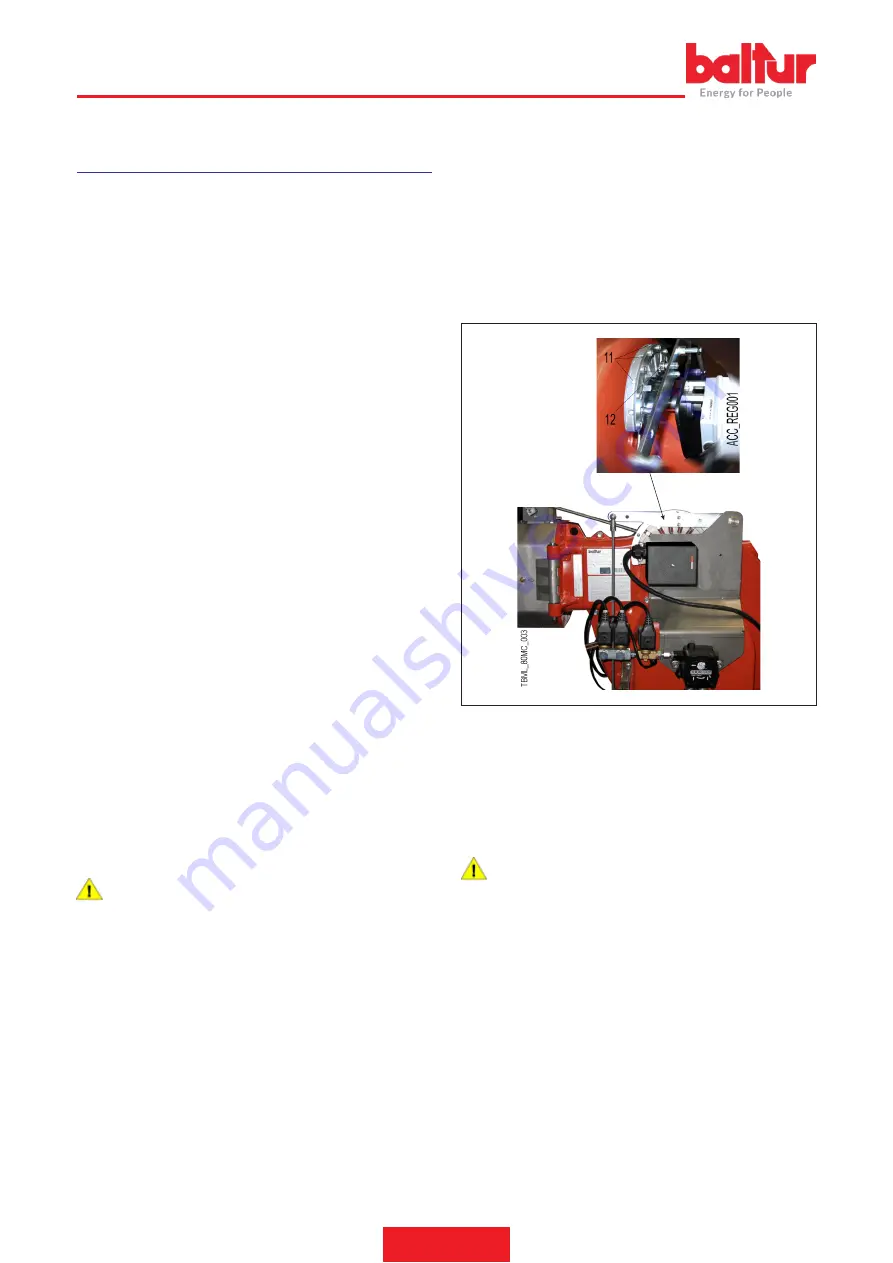

Adjust the quantity of air necessary for the maximum flow rate

(2nd stage) through the screw/s at the bearing (12).

- in a clockwise direction the air flow increases

- in an anti-clockwise direction the air flow decreases

•

During burner ignition, when it passes to the first stage, the air/

gas servomotor takes for a few seconds the burner to a delivery

higher than the first stage.

•

During this transition phase check that the cam (IV) for actuating

the servomotor second stage does not activate.

TBML_ACC_REG_001

THERMAL RELAY CALIBRATION

The thermal relay prevents motor failure due to a large increase in

electric absorption, or the lack of single-stage.

For calibrating, please refer to the nominal value of the motor

current.

To reset the burner, if the thermal relay trips, press the reset button

(RESET).

DANGER / ATTENTION

The automatic reset may be dangerous thus, when possible,

do not set this function on the thermal relay.

Summary of Contents for TBML 200 MC

Page 2: ......

Page 48: ...ITALIANO 46 54 0006081544_201907 SCHEMI ELETTRICI ...

Page 49: ...ITALIANO 47 54 0006081544_201907 ...

Page 50: ...ITALIANO 48 54 0006081544_201907 ...

Page 52: ...ITALIANO 50 54 0006081544_201907 ...

Page 53: ...ITALIANO 51 54 0006081544_201907 ...

Page 54: ...ITALIANO 52 54 0006081544_201907 ...

Page 56: ...ITALIANO 54 54 0006081544_201907 ...

Page 102: ...ENGLISH 46 54 0006081544_201907 WIRING DIAGRAMS ...

Page 103: ...ENGLISH 47 54 0006081544_201907 ...

Page 104: ...ENGLISH 48 54 0006081544_201907 ...

Page 106: ...ENGLISH 50 54 0006081544_201907 ...

Page 107: ...ENGLISH 51 54 0006081544_201907 ...

Page 108: ...ENGLISH 52 54 0006081544_201907 ...

Page 110: ...ENGLISH 54 54 0006081544_201907 ...

Page 111: ......