ENGLISH

45 / 60

0006160032_201711

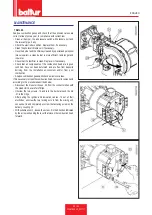

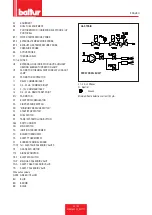

TROUBLESHOOTING INSTRUCTIONS

ANOMALY

The burner does not start up.(The

equipment does not perform the

start up program).

Poor flame, with sparks.

Poorly shaped flame with smoke

and soot.

Defective flame, flickering or

protruding from combustion head.

POSSIBLE CAUSE

1

Thermostats (boiler or room) or

pressure switches are open.

2

Photoresistant-cell in short circuit.

3

Absence of line voltage, main switch

open, meter switch tripped or absence

of line voltage.

4

Thermostat line not wired according to

diagram or open thermostats.

5

Equipment internal fault.

1

Spraying pressure is too low.

2

Too much combustion air.

3

Nozzle inefficient because dirty or

worn.

4

Water in the fuel.

1

Insufficient combustion air flow.

2

Nozzle inefficient because dirty or

worn.

3

Nozzle capacity too low with respect to

combustion chamber volume.

4

Combustion chamber unsuitably

designed or too small.

5

Unsuitable refractory coating (it

reduces excessively the space of the

flame).

6

Boiler or chimney ducts blocked.

7

Spraying pressure is low.

1

Excessive draught, only when there is

an extractor in the chimney.

2

Nozzle inefficient because dirty or

worn.

3

Water in the fuel.

4

Dirty deflector disk.

5

Too much combustion air.

6

Air passage between deflector disk

and diffuser excessively closed.

REMEDY

1

Raise the thermostats settings, or

wait that the contacts close for natural

decrease of temperature or pressure.

2

Replace it.

3

Activate switches or wait for power to

return.

4

Check the connections and thermostats.

5

Replace it.

1

Restore it at the required value.

2

Reduce combustion air

3

Clean or replace.

4

Drain water from the tank using a suitable

pump. Never use the burner pump for this

purpose.

1

Increase combustion air.

2

Clean or replace.

3

Decrease diesel flow rate to suit the

chamber (thermal power will obviously

be lower than necessary) or replace the

boiler.

4

Increase nozzle flow by replacing it.

5

Modify it, carefully abiding by the

instructions given by boiler manufacturer.

6

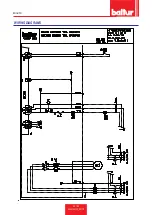

Arrange for cleaning.

7

Restore it at the required value.

1

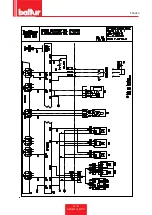

Adjust the suction fan speed by changing

the pulley diameter.

2

Clean or replace.

3

Drain water from the tank using a suitable

pump. Never use the burner pump for this

purpose.

4 Clean.

5

Reduce combustion air.

6

Correct the position of the combustion

head regulating device.

Summary of Contents for TBML 80 ME

Page 2: ......

Page 4: ...ITALIANO 2 60 0006160032_201711 ITALIANO Schemi elettrici 48...

Page 50: ...ITALIANO 48 60 0006160032_201711 SCHEMI ELETTRICI...

Page 51: ...ITALIANO 49 60 0006160032_201711...

Page 52: ...ITALIANO 50 60 0006160032_201711...

Page 53: ...ITALIANO 51 60 0006160032_201711...

Page 54: ...ITALIANO 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 56: ...ITALIANO 54 60 0006160032_201711...

Page 57: ...ITALIANO 55 60 0006160032_201711...

Page 58: ...ITALIANO 56 60 0006160032_201711...

Page 59: ...ITALIANO 57 60 0006160032_201711...

Page 60: ...ITALIANO 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 62: ......

Page 64: ...ENGLISH 2 60 0006160032_201711 ENGLISH Wiring diagrams 48...

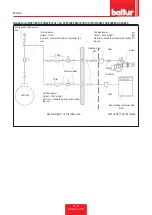

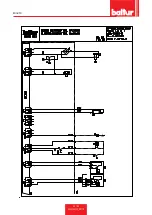

Page 110: ...ENGLISH 48 60 0006160032_201711 WIRING DIAGRAMS...

Page 111: ...ENGLISH 49 60 0006160032_201711...

Page 112: ...ENGLISH 50 60 0006160032_201711...

Page 113: ...ENGLISH 51 60 0006160032_201711...

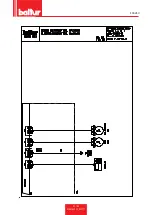

Page 114: ...ENGLISH 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

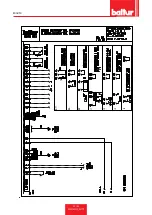

Page 116: ...ENGLISH 54 60 0006160032_201711...

Page 117: ...ENGLISH 55 60 0006160032_201711...

Page 118: ...ENGLISH 56 60 0006160032_201711...

Page 119: ...ENGLISH 57 60 0006160032_201711...

Page 120: ...ENGLISH 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 122: ......

Page 123: ......