ENGLISH

32 / 60

0006160032_201711

•

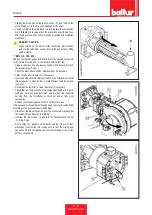

With the switch on the burner panel at the position “0” and the main

switch on, check, closing the contactor manually, that the motor

rotates in the right direction. If necessary, swap the two power

cables for the motor around to change the direction of rotation.

•

If using the inverter, see the specific instructions in the quick guide.

• Now switch on the main switch. This powers on the control device,

and the programmer turns on the burner as described in the

chapter "Operation description". For burner adjustment, refer to the

instructions for the electronic cam supplied.

•

After having adjusted the “minimum”, (200) bring the burner to the

maximum, using the controls on the electronic cam keyboard.

•

We recommend that you check the combustion using the

appropriate instrument at all intermediate points on the modulation

route (from 200 to 999), checking the gas flow rate by reading the

meter.

•

It is essential to check, using an appropriate instrument, that the

percentage of carbon monoxide (CO) present in the fumes does

not exceed the limit set by the regulations in force at the time of

installation.

•

Now check the proper automatic operation of modulation. This

ensures that the equipment receives the signal from the electronic

modulation regulator, if the burner is the modulating model, or from

the second stage thermostat or pressure switch, if it is a two stage

progressive burner.

•

Check combustion using the appropriate instrument at all

intermediate points on the modulation route (from minimum to

maximum load), checking also the gas flow rate reading the meter.

•

Now, check for the efficiency of automatic modulation operation by

switching the ETAMATIC apparatus to the “AUTOMATIC” position.

With this setting modulation will start only by using the automatic

control of the boiler probe.

DANGER / CAUTION

The burner must not operate below the specified minimum flow

rate to prevent damage to the components of the combustion

head.

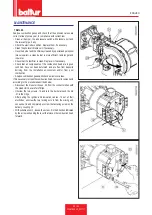

FLAME SENSOR

Verify the flame detector operation as follows:

•

extract the photocell from its seat;

•

Start up the burner;

•

The control box will complete the control cycle and after two

seconds will lock the burner due to the lack of ignition flame;

•

switch off the burner;

•

reposition the photocell;

•

This test should be carried out with the burner already on; the

apparatus should lock out immediately when the wire from the

ionisation electrode is disconnected.

•

Check for the efficiency of the thermostats or boiler pressure

switches (they should shut down the burner when triggered).

AIR PRESSURE SWITCH

The air pressure switch stops the equipment operation if air pressure

is not at the expected value.

The pressure switch must therefore be adjusted so that it is triggered

to close the NO contact (normally open) when the air pressure in the

burner reaches a particular value.

If the air pressure switch does not detect a pressure greater than that

calibrated, the equipment runs through its cycle but does not switch

on the ignition transformer and does not open the gas valves and so

the burner “locks-out”.

To ensure correct operation of the air pressure switch you must, with

burner on and in 1st stage, increase its regulation value until the

burner triggers and then it immediately “locks-out”.

Release the burner by pushing the appropriate button and readjust

the pressure switch to a sufficient value to detect the existing air

pressure during the pre-ventilation phase of the first stage.

Air pressure sampling point is downstream the air damper.

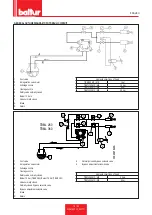

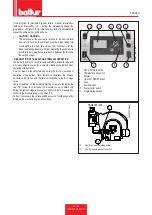

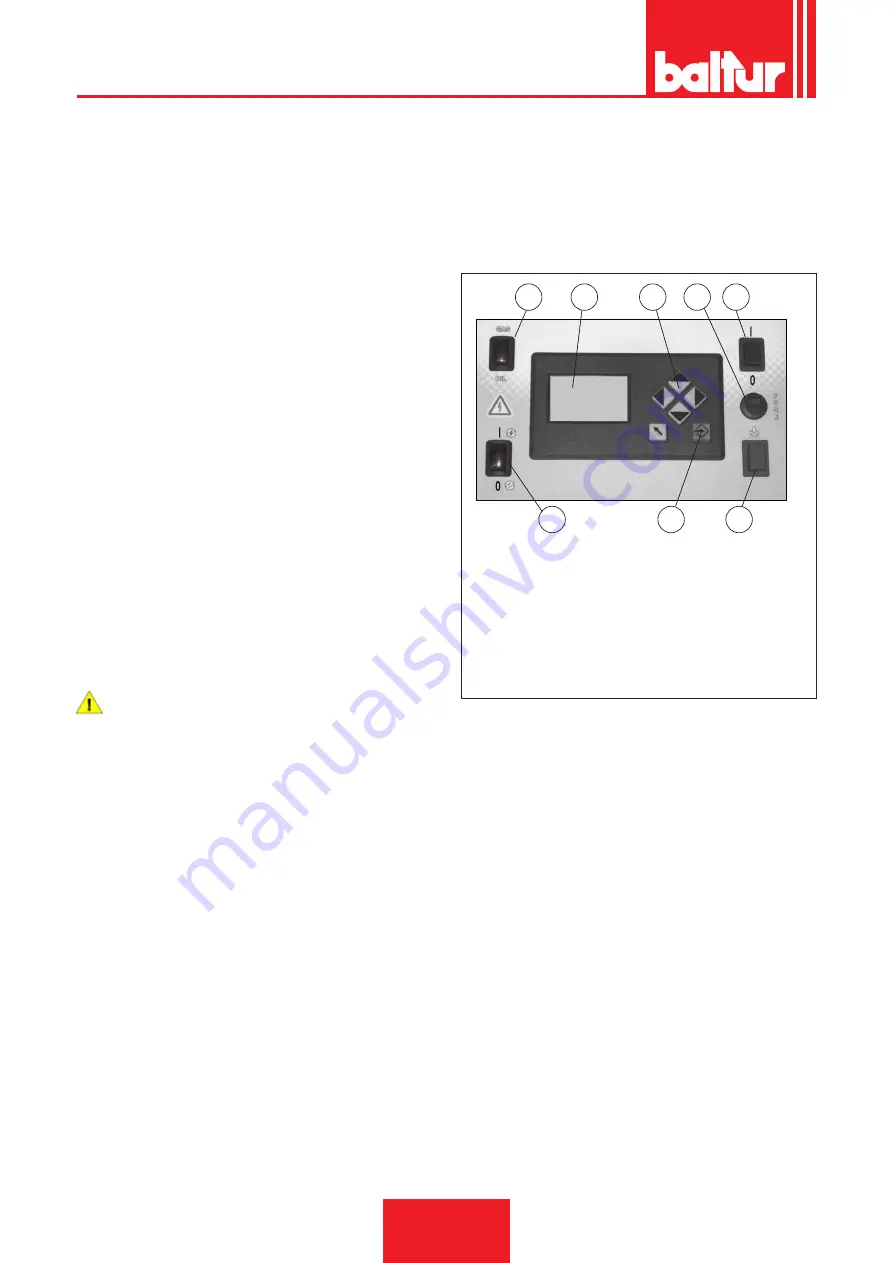

1

2

10

3

4

9

11

5

display_TBML_ME

1 ON / OFF main switch.

2 Thermostatic line switch

3 Display

4 Unlock or RESET button

5 Fuse.

9 Fuel fill button

10 Fuel selector switch

11 Programming keypad

Summary of Contents for TBML 80 ME

Page 2: ......

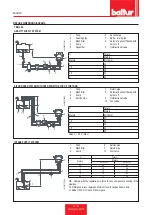

Page 4: ...ITALIANO 2 60 0006160032_201711 ITALIANO Schemi elettrici 48...

Page 50: ...ITALIANO 48 60 0006160032_201711 SCHEMI ELETTRICI...

Page 51: ...ITALIANO 49 60 0006160032_201711...

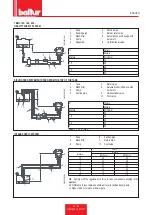

Page 52: ...ITALIANO 50 60 0006160032_201711...

Page 53: ...ITALIANO 51 60 0006160032_201711...

Page 54: ...ITALIANO 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 56: ...ITALIANO 54 60 0006160032_201711...

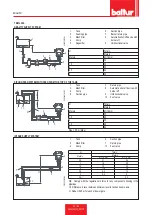

Page 57: ...ITALIANO 55 60 0006160032_201711...

Page 58: ...ITALIANO 56 60 0006160032_201711...

Page 59: ...ITALIANO 57 60 0006160032_201711...

Page 60: ...ITALIANO 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 62: ......

Page 64: ...ENGLISH 2 60 0006160032_201711 ENGLISH Wiring diagrams 48...

Page 110: ...ENGLISH 48 60 0006160032_201711 WIRING DIAGRAMS...

Page 111: ...ENGLISH 49 60 0006160032_201711...

Page 112: ...ENGLISH 50 60 0006160032_201711...

Page 113: ...ENGLISH 51 60 0006160032_201711...

Page 114: ...ENGLISH 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 116: ...ENGLISH 54 60 0006160032_201711...

Page 117: ...ENGLISH 55 60 0006160032_201711...

Page 118: ...ENGLISH 56 60 0006160032_201711...

Page 119: ...ENGLISH 57 60 0006160032_201711...

Page 120: ...ENGLISH 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 122: ......

Page 123: ......