ENGLISH

37 / 60

0006160032_201711

SPECIFICATIONS FOR PROPANE USE

•

Operating costs approximate assessment;

- 1 m3 of liquid gas in gaseous stage has a lower heating

capacity, of nearly 25.6 kWh.

- To obtain 1 cu.m of gas, about 2 kg of liquid gas are needed,

i.e. about 4 litres of liquid gas.

•

Safety provisions

•

Liquid propane gas (L.P.G.) in the gaseous form has a greater

specific weight than air (specific weight relative to air = 1.56 for

propane), which means it does not disperse in air like natural

gas, which has a lower specific weight than air (specific weight of

natural gas relative to air = 0.60), but precipitates and spreads out

at ground level (as if it were a liquid). Summing up the concepts we

deem most relevant for the use of LPG

•

Liquefied petroleum gas (L.P.G.) burners and/or boilers may be

used only in premises located above ground level and certified

toward free spaces. Installations using liquid gas are not allowed in

underground or semi-underground premises.

•

The rooms in which LPG is used must be fitted with adequate

ventilation slots on external walls without closing devices in

accordance with the regulations in force.

•

Performance of the LPG system to ensure correct and safe

operation.

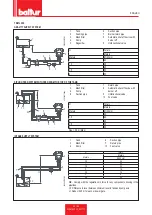

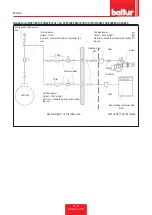

Natural gasification, from a cylinder bank or tank, can be used

only for systems having low power. The following table gives an

approximate indication of the gas output capacity according to the

tank size and minimum outdoor temperature.

DANGER / CAUTION

The burner's minimum and maximum output (kW) is rated

based on its use with methane gas which more or less

corresponds to the power values obtained with propane gas.

•

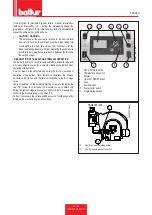

Combustion testing

To limit consumption and avoid serious trouble, adjust combustion

by using the appropriate instruments. It is absolutely essential

to check that the percentage of carbon monoxide (CO) does not

exceed the maximum value permitted by the regulations in force

(use a combustion analyser).

DANGER / CAUTION

The warranty does not cover burners burning liquid gas (L.P.G.)

in installations in which these measures have not been taken.

Minimum

temperature

- 15 °C

- 10 °C

- 5 °C

- 0 °C

+ 5 °C

990 l tank

1.6 Kg/h 2.5 Kg/h 3.5 Kg/h

8 Kg/h

10 Kg/h

3000 l tank

2.5 Kg/h 4.5 Kg/h 6.5 Kg/h

9 Kg/h

12 Kg/h

5000 l tank

4 Kg/h

6.5 Kg/h 11.5 Kg/h 16 Kg/h

21 Kg/h

Summary of Contents for TBML 80 ME

Page 2: ......

Page 4: ...ITALIANO 2 60 0006160032_201711 ITALIANO Schemi elettrici 48...

Page 50: ...ITALIANO 48 60 0006160032_201711 SCHEMI ELETTRICI...

Page 51: ...ITALIANO 49 60 0006160032_201711...

Page 52: ...ITALIANO 50 60 0006160032_201711...

Page 53: ...ITALIANO 51 60 0006160032_201711...

Page 54: ...ITALIANO 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 56: ...ITALIANO 54 60 0006160032_201711...

Page 57: ...ITALIANO 55 60 0006160032_201711...

Page 58: ...ITALIANO 56 60 0006160032_201711...

Page 59: ...ITALIANO 57 60 0006160032_201711...

Page 60: ...ITALIANO 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 62: ......

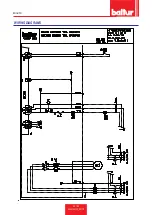

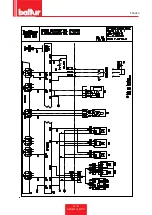

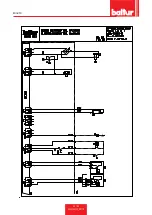

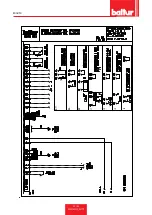

Page 64: ...ENGLISH 2 60 0006160032_201711 ENGLISH Wiring diagrams 48...

Page 110: ...ENGLISH 48 60 0006160032_201711 WIRING DIAGRAMS...

Page 111: ...ENGLISH 49 60 0006160032_201711...

Page 112: ...ENGLISH 50 60 0006160032_201711...

Page 113: ...ENGLISH 51 60 0006160032_201711...

Page 114: ...ENGLISH 52 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 116: ...ENGLISH 54 60 0006160032_201711...

Page 117: ...ENGLISH 55 60 0006160032_201711...

Page 118: ...ENGLISH 56 60 0006160032_201711...

Page 119: ...ENGLISH 57 60 0006160032_201711...

Page 120: ...ENGLISH 58 60 0006160032_201711 BT1 BA BP I1 I2 I3 I4...

Page 122: ......

Page 123: ......