18

1) Check that the characteristics of the nozzle (delivery and spray angle) are suitable for the furnace (see BT 9353/1).

If not, replace it.

2) Check that there is fuel in the cistern and that it is, at least visually, suitable for the burner.

3) Check that there is water in the boiler and that the system’s gate valves are open.

4) Check, with absolute certainty, that the discharge of combustion products can take place freely (boiler and chimney

lock-gates should be open).

5) Make sure that the voltage of the electric line to which the burner is to be connected, corresponds to that required

by the burner, and that the motor’s electrical connections and resistances have been correctly prepared to match

the voltage rating available. Also check that all the electrical connections carried out on the spot are in accordance

with our electric wiring diagram.

6) Make sure that the combustion head is long enough enter into the furnace to the extent specified by the boiler

manufacturer.

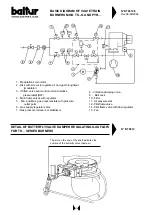

7) Remove the protective cover from the rotating disk inserted on the modulation servomotor. On this disk have

been fitted adjustable screws which are used to control the fuel and the relative combustion air.

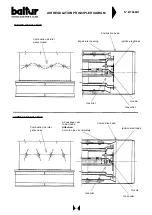

8) Check that the air regulation device on the combustion head is in the position considered necessary for the fuel

delivery required (the air passage between the disk and the head should be considerably closed when the fuel

delivery is relatively reduced; on the other hand, when the nozzle has a fairly high delivery, the air passage

between the disk and the head should be relatively open (see Chapter “Regulation of the Combustion Head”).

9) Put the two modulating switches in the “MIN” (minimum) and “MAN” (manual) positions.

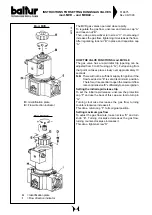

10) Check that the minimum and regulation thermostats of the pre-heater have been correctly regulated for the type

of fuel to be used. By knowing the nominal viscosity value of the fuel intended for use and by referring to the

Viscosity-Temperature diagram, it is possible to find the exact pre-heating temperature necessary for the fuel oil.

It should be kept in mind that the fuel should arrive at the nozzle with a viscosity rate not exceeding 2° E.

To avoid interferences which would bring the burner to a standstill, it is necessary to set the regulation thermostat

at a temperature 15 ÷ 20° C higher with respect to the minimum thermostat. After starting up the burner check that

the thermostats operate correctly by controlling the thermometer on the pre-heater.

Regulate at about 50° C the control thermostat of the resistance which is incorporated in the line filter.

N.B. For the preheater/s thermostat/s adjustment, see the specific instructions of the MS 30 electronic regulator,

which jou find in the following pages.

11) Start up the fuel supply auxiliary circuit, check its efficiency and regulate the pressure at about 1 bar.

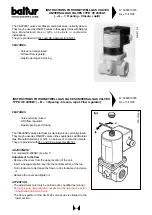

12) Remove from the burner pump the vacuumeter connection point plug and then open slightly the gate valve fitted

on the fuel arrival pipe. Wait until fuel comes out of the hole, without air bubbles, and then re-close the gate valve.

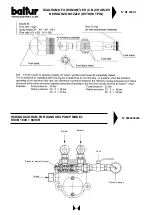

13) Insert a manometer (end of the scale about 3 bar) into the vacuumeter connection point on the pump and control

the value of the pressure at which the fuel arrives at the burner pump. Insert a manometer (end of the scale about

30 bar) into the manometer connection point provided on the pump and control its working pressure.

Insert a manometer (end of the scale about 30 bar) into the special connection point of the return pressure

regulator in order to control the value which determines delivery (see BT 8867).

14) Put the switch on the control panel in the “O” (open) position to avoid the resistances being inserted with an empty

tank, and give current to the electric lines which the burner is connected to. Check, by pressing manually the

relative relay, that the fan and pump motors rotate in the right direction. If they do not, exchange the places of two

cables of the principle line in order to inverse the sense of rotation.

15) Start operating the burner pump by pressing manually on the relative relay until the manometer, which measures

the working pressure of the pump, indicates a slight pressure. The presence of low pressure in the circuit confirms

that filling up of the pre-heater tank has taken place.

16) Connect the switch on the control panel to give current to the control box. In this way, and on the command of the

relative thermostat, the resistances which heat the fuel in the tank and that which heats the line filter will be

inserted. At the same time (but only for models ...D) the resistances for heating the atomizer group and the pump

are inserted. The pilot light on the control panel will indicate when the resistances have been inserted.

STARTING UP AND REGULATION WITH FUEL OIL

Summary of Contents for TS 0 GN

Page 2: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......