32

INSTRUCTIONS FOR VALVES EQUIPPED WITH

PRESSURE REGULATOR mod. SKP 20....

N° 8882-GB

rev. 06/11/90

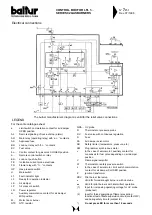

DESCRIPTION OF HOW THE VALVE OPERATES

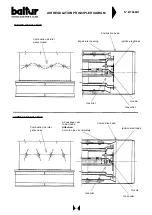

Servomotor

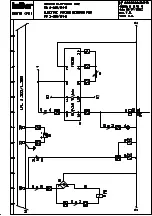

The hydraulic control system consist of a cylinder filled with oil and oscillating piston pump. There is also a

solenoid valve between the intake chamber and the pump thrust chamber, to close the valve. The piston moves

against a sealed joint inserted into the cylinder; in turn, this joint hydraulically separates the intake chamber from

the delivery chamber. The piston transmits the stroke directly to the valve. A disk is secured to the valve shaft

and can be seen through a slit in the valve, indicating the stroke.

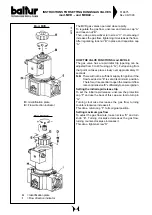

PRESSURE REGULATOR

The pressure regulator consists of a diaphragm (there is also an additional safety diaphragm), a spring calibrated

to a setpoint and an oscillating system to drive the ball valve located on the bypass between the hydualic system

intake and delivery chambers (also see “Description of how the valve works”).

Operating range: 0...22 mbar or (subject to replacement of the spring) up to 250 mbar.

Regulation to the set value can be sealed. Gas pressure inlet connection starting at

1

/

4

”.

Thanks to the use of a safety diaphragm, no gas vent piping is required for inlet pressure up to 100 mbar. Under

tightness testing, it can tollerate a vacuum pressure of up to 200 mbar.

The casing of the servomotor and the pressure regulator are in cast aluminum.

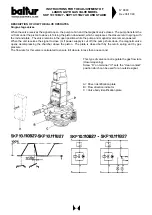

DESCRIPTION OF HOW GAS VALVES FITTED WITH PRESSURE REGULATOR OPERATE

When a valve fitted with a pressure regulator is used, the valve outlet pressure presses against a spring-assisted

diaphragm, acting as a reference value. The force of this spring can be adjusted and is set at the prescribed

value. The diaphragm, activated by an oscillating piston system, presses against the ball bypass valve located

between the lower and upper chambers of the servocontrol unit. If the reference value is lower than the setpoint,

the bypass is closed so that the servocontrol can open the gas valve. On the contrary, if the reference value is

higher than the setpoint, the bypass is open a degree enabling oil to return to the lower chamber.

The gas valve closes gradually until setpoint coincides with the gas reference pressure value. When this well-

balanced position is reached, the bypass is open so that flow rate corresponds to pump flow rate.

In this way, the regulator operates as a proportional regulator over a very narrow range. Nevertheless, regulation

remains stable because the speed at which the valve closes is reduced.

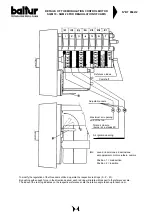

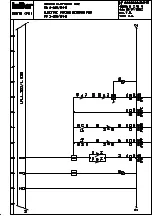

Remove screw cap cover “C” to access the

pressure regulation screw “A”.

Tighten to increase the pressure, loosen to

decrease the pressure.

Screw “D” in terminal “IV” regulates the position

at which the “clean” contact is activated.

This can be used for an outside signal.

D = Driver identification plate

E = Flow direction indicator

F = Valve body identification plate

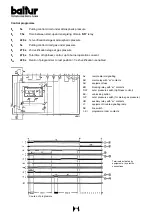

B

type

Po

colour

(mm)

(mbar)

1,0

--

< 22

bright

1,6

AGA22

< 120

yellov

1,6

AGA 23

< 250

red

Summary of Contents for TS 0 GN

Page 2: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......