6

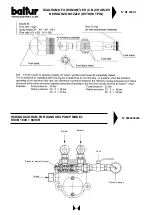

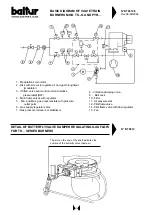

GAS (METHANE) FEED SYSTEM FROM THE GAS PIPE NETWORK AND AVERAGE PRESSURE

(See BT 8530/1 and BT 8531/1)

When high delivery is required, the Gas Distributing

Company requests the installation of a unit comprising a

pressure reducer and a meter, and then connects the

gas feed system to the gas pipe network at average

pressure (a few bar).

This unit can be supplied by the Gas Distributing

Company or by the user, but should be according to the

Gas Company’s precise instructions.

The unit’s pressure reducer should be large enough to

supply the maximum gas delivery required by the burner

at the rate of pressure normally estimated for it.

From experience, we would recommend utilizing a large-

sized reducer in order to attenuate the notable increase

in pressure which occurs when the burner comes to a

standstill, with a high delivery.

(Regulations require that the gas valves close in less

than one second).

As an indication, we would advise using a reducer

capable of producing a delivery (m

3

/h) about double that

of the maximum amount estimated for the burner.

If several burners are to be used, each one should have

its own pressure reducer;

this will enable the gas feed pressure to the burner to be

maintained at a constant level even if only one burner is

operating at the time.

Consequently, it is possible to accurately regulate the

delivery and therefore the combustion, and thus improve

yield.

The dimension of the gas pipeline should be in function

with the quantity of gas it has to delivery. We advise

maintaining the load loss at a low value, it should be

kept in mind that the load loss is added to the pressure

existing when the burner stops and therefore a

subsequent start up will occur at a pressure that rises in

accordance with an increase in the pipe’s load loss.

Should the gas pressure reach unacceptable values

when the burner stops (rapid closure of the gas valves),

it is necessary to install between the reducer and the

first valve of the burner an automatic overflow valve and

relative conveying pipe, of suitable section, in the open

air.

The end of the conveying pipe in the open air should terminate in a suitable place, be protected from rain and have a

flame trap.

The overflow valve should be regulated in such a way as to completely unload excessive pressure.

See diagram for gas pipeline dimensions.

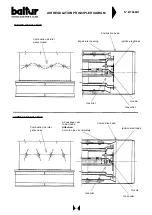

DIAGRAM FOR CALCULATING THE DIAMETER OF

THE PIPES IN RELATION TO THEIR LENGTH AND

GAS FLOW

N° BT 8058

FLOW IN m

c

/h of METHANE GAS s.a. 0,60

LENGHT OF PIPES IN METERS

DIAMETER OF PIPES IN INCHES

PRESSURE DROP IN mm OF H

2

0

Summary of Contents for TS 0 GN

Page 2: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......