IT5000-C / IT6000-C

3/8” IT Tool

www.BAND-IT-IDEX.com

Document # P48850 Rev. C

© Copyright

BAND-IT-IDEX, Inc. 2015

All rights reserved

Page 24 of 36

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

Operating

Manual

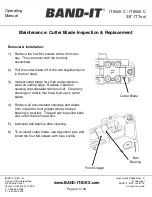

Cutoff Signal Option

The cut-off signal option provides a signal from the tool that indicates the completion of a

clamp installation. Pressurization of the cut-off cylinder activates a pressure switch when

the tool switches from the tension cycle to the cut-off cycle. The pressure switch is

“normally open” and closes to complete a circuit when cut-off cylinder pressure exceeds

45±15 psi during cutoff cycle. The signal can be transmitted to a data collection device,

such as a PLC, via the 12-foot extension cable and used as a counter to track the number

of clamps applied by the tool. The switch has a maximum voltage rating of 42V.

Contact BAND-IT IDEX Customer Service at 1-800-525-0758 or 303-320-4555 for

any questions not addressed above.

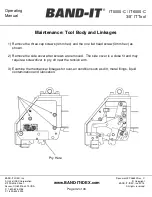

Mounting Hole:

½”-14 NPT

Or

.85” diameter clearance hole for ½”-14 lock nut

The -002 and -012 configurations are tool

systems that also come with a 12-foot

extension cable (I60387), female receptacle

(I60487) and electric panel lock nut (I61187)

for mounting to a PLC or other control box. The

polarity of the 2 wire leads from the receptacle

is not critical.

An IT Tool with configurations -102 and -112

contain the pressure switch and 2 pole Micro

AC series male receptacle.