BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-0307 USA

P: 1-800-525-0758

F: 1-800-624-3925

Document # P07886 Rev. L

© Copyright

BAND-IT-IDEX, Inc. 2010

All rights reserved

www.BAND-IT-IDEX.com

Page 5 of 14

UL4000

Ultra-Lok

Tool

Settings

NOTE: When tightening the adapter clamping screw, safety clutch (M21790) must be engaged

with tension screw inside of BAND-IT tool.

Important:

Changing speed setting will alter tension output. Speed setting must remain at

1

when

applying tension to the clamp tail. Drill switch must be depressed fully by the operator to attain

correct tension when installing clamps. Tension output may be somewhat different from tool to

tool on the same setting, depending on condition and wear of internal components.

Caution: Improperly tightened clamps may result in dangerous assemblies, which could cause

injuries or property damage.

Using correctly sized clamps (diameter) will, in most cases, eliminate the need to pull on clamp

tail more than once. Tension block moves approximately 5”. On occasion, if needed, large size

clamps can be installed by taking several bites (clamp tail feeds out through back of tool).

Position of tension block, containing gripper, can be monitored through viewing holes just under

cut-off handle. Tool features built-in, disengaging mechanism to prevent tension screw from

jamming up. Excessive use of this feature will wear clutch mechanism and/or tension screw out

prematurely.

CAUTION !

The UL4000 tool is designed to work mounted to the DeWalt DC987/DW987/DC925 cordless drill. Use of any other

drills in place of the DeWalt may result in unsatisfactory performance, hazards to the operator and/or the tool, or

unsafe clamps. Use of alternate drills must be approved in writing by the Director of Engineering at BAND-IT-IDEX,

Inc. Disregard of this caution voids the warranty of the tool and releases BAND-IT of any and all liabilities arising

from such misuses.

Use of Alternate Drills

NOTE:

These torque settings are suggested settings only, individual tools should be

adjusted for the clamping application.

The tool accompanying this manual was function tested at a clutch setting of __________

and produced a pull-up force of _____________ lbf.

Serial #__________________Tested by:________________ Test date:_______________

*IMPORTANT:

Larger sizes of preformed clamps (5" and up) may require a lower setting

to avoid over-stressing the lock and creating potentially unsafe assemblies. Inspect lock per

instructions on page 9-11.

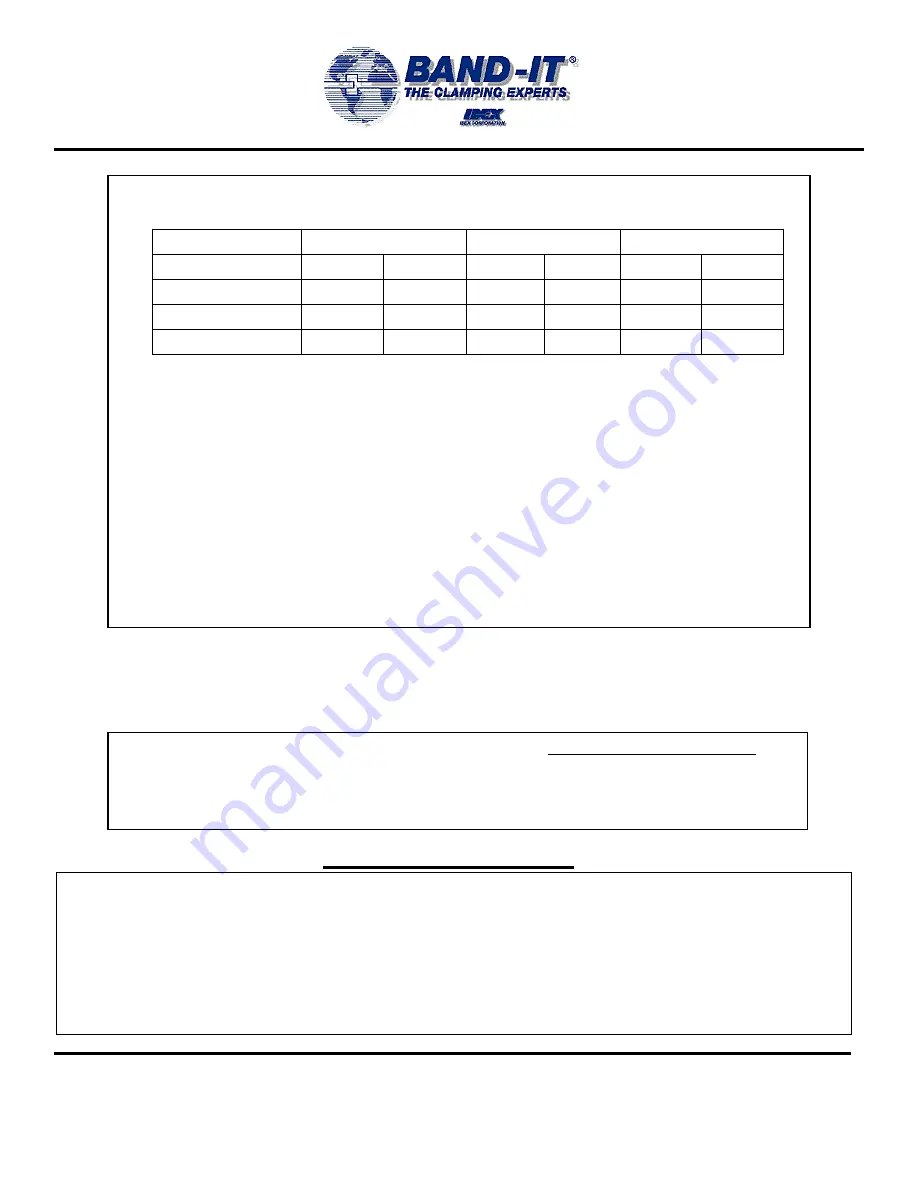

Recommended Drill Clutch Torque Settings:

Drill Model

DC987

DW987

DC925

Clamp Size

¾”

½”

¾”

½”

¾”

½”

Single Wrap

11-13

5-9

5-7

4-6

11-15

3-7

Double Wrap

17-22

11-13

15-19

5-7

19-20

11-15

*Preformed

17-22

11-13

15-19

5-7

19-20

11-15

Always Set Speed Selector to “1”