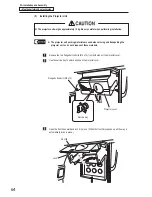

– Must be performed by a technician –

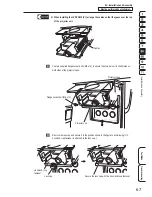

62

8A. Installation and Assembly

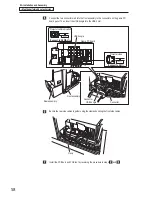

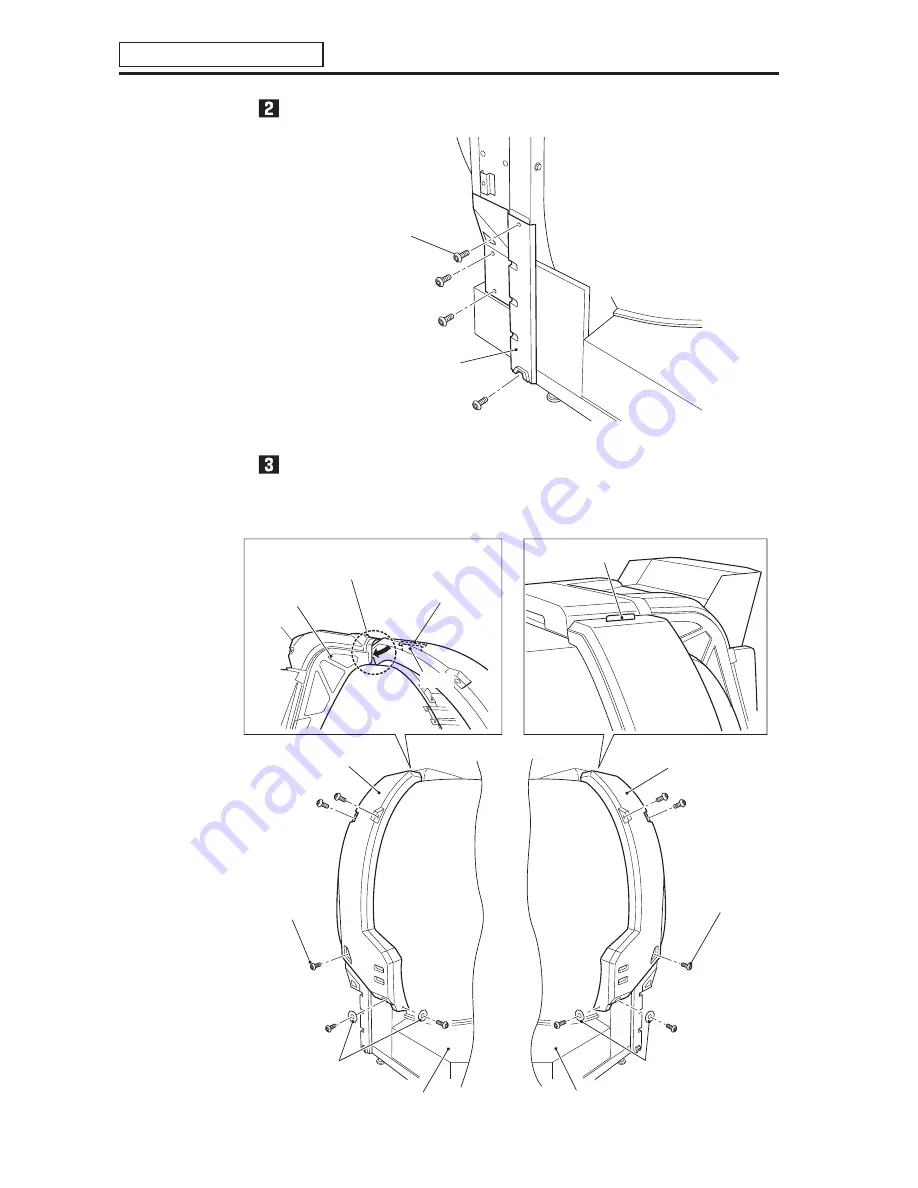

Use four supplied Torx bolts (black) (M5 x 12) to install the supplied lower side cover (R).

Torx bolt (black) (M5 x 12)

Lower side cover (R)

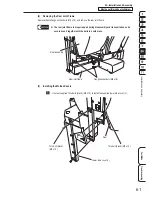

Hook the slot at the top of the supplied side cover (L) onto the hook, then install the side cover

(L) and secure it using five supplied Torx bolts (silver) (M5 x 12) and two flat washers (ø5 x

16). Perform the same procedure to also install the side cover (R).

Side cover (L)

Side cover (R)

Hook

Torx bolt (silver)

(M5 x 12)

Front assembly

Flat washer (ø16 x ø5)

Flat washer (ø16 x ø5)

Front assembly

Torx bolt (silver)

(M5 x 12)

Slot in side cover (R)

Top cover

When installing the side cover (R),

insert it under the top cover.

Hook