-2-

INDEX

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 4

Air Supply: Fittings, Hoses, Filters, Air Consumption, Regulators,

Operation Pressure, Setting Correct Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

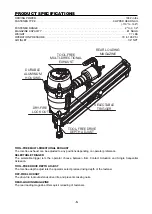

Production Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Depth Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Loading the Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tool Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9, 10

Maintaining the Pneumatic Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

WARRANTY

B&C Eagle brand tools carry a 3 YEAR limited warranty to the original purchaser. If the tool fails within 3

years from the date of purchase, simply return the tool to your nearest B&C Eagle dealer with your receipt.

We will repair or replace the tool at NO CHARGE. This limited warranty does not cover any damage that

has resulted from abuse or misuse of the tool, and does not cover normal wear parts such as O-Rings,

Springs, Bumpers, Driver Units and other consumable items. Be careful, tools are dangerous if improperly

used or maintained. Seller's employees are not qualified to advise you on the use of these tools. Oral

representation will not be binding on the Seller. The rights under this limited warranty are to the original

purchaser and may not be transferred to the subsequent owner. This limited warranty is in lieu of all

warranties, expressed or implied including warranties of merchantability and fitness for a particular purpose.

Seller shall not be liable for any special, incidental or consequential damages. The sole exclusive remedy

against the seller will be for the replacement of any defects as provided herein, as long as the seller is willing

or able to repair or replace the tool as provided above. This exclusive remedy shall not be deemed to have

failed of its essential purpose.

CUSTOMER SERVICE INFORMATION

Now that you have purchased your tool, should a need ever exist for repair parts or service, simply contact

your nearest B&C Eagle dealer or call American Fastening Systems: 1-877-842-1234. Be sure to provide

the pertinent facts when you call or visit.