8

Mounting BC3500

Correct mounting of the BC3500 is the customers responsibility.

Before mounting your BC3500 inspect for and signs of possible damage and all assembly

bolts and screws are secure.

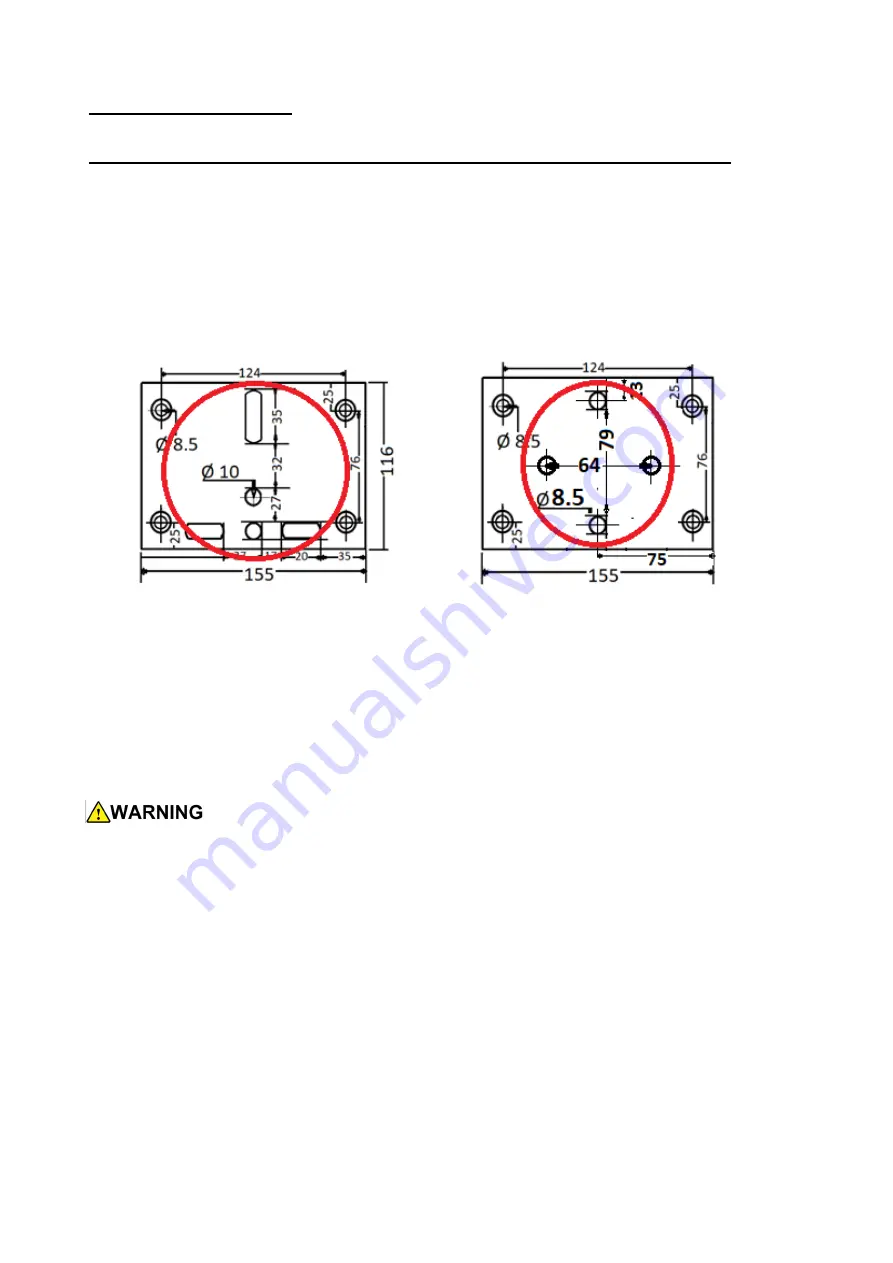

Mounting hardware must be of a minimum M8 high tensile grade 8 bolts.

M10 bolts may be used with non hawse mount plate.

Dimensional diagram shows cut outs in mounting plate for suitable securing positions.

A minimum of two mounting bolts must be used being centre holes front hole and rear.

The bolts must be secured with spring washer behind the nut or lock nut should be used.

Two flat washers should be used on the bolts on both sides of the mounting plate one un-

der the bolt head and one under the lock washer or lock nut. Ensure all nuts are firmly

secured at 30 Nm of torque for M8.

The use of undersized or under strength bolts can result in the mounting failing under

load. This can result in injury, death or damage.

The mounting platform or structure must be of adequate strength to support the full line

pull capability of the winch. Plus incorporate a safety factor which will eliminate possible

distortion of the mounting platform. A steel mounting platform of 6mm thickness may be

required. Seek qualified engineering support if uncertain.

The BC3500 must be located in a position it will not be submerged in water.

The BC3500 can be mounted horizontally or inverted but must be mounted so the rope

feeds on in a direct straight line either from the load or via a pulley block.

When mounted the rope must feed onto the winch drum from the underside of the drum

when looking at the winch with the motor to the left and gearbox on the right.

Incorrect installation of the rope will eliminate the load holding mechanical brake.

Summary of Contents for BC3500

Page 6: ...6 Dimensions BC3500ATV...

Page 7: ...7 Dimensions BC3500 control box...

Page 13: ...13 BC3500 parts exploded view...