The ironer must be lifted at its center (center of gravity on the axis).

Do not drop or turn the ironer over, e.g. when unloading.

Note: lifting with slings or straps is not recommended, as there is a imminent risk of damaging

the ironer.

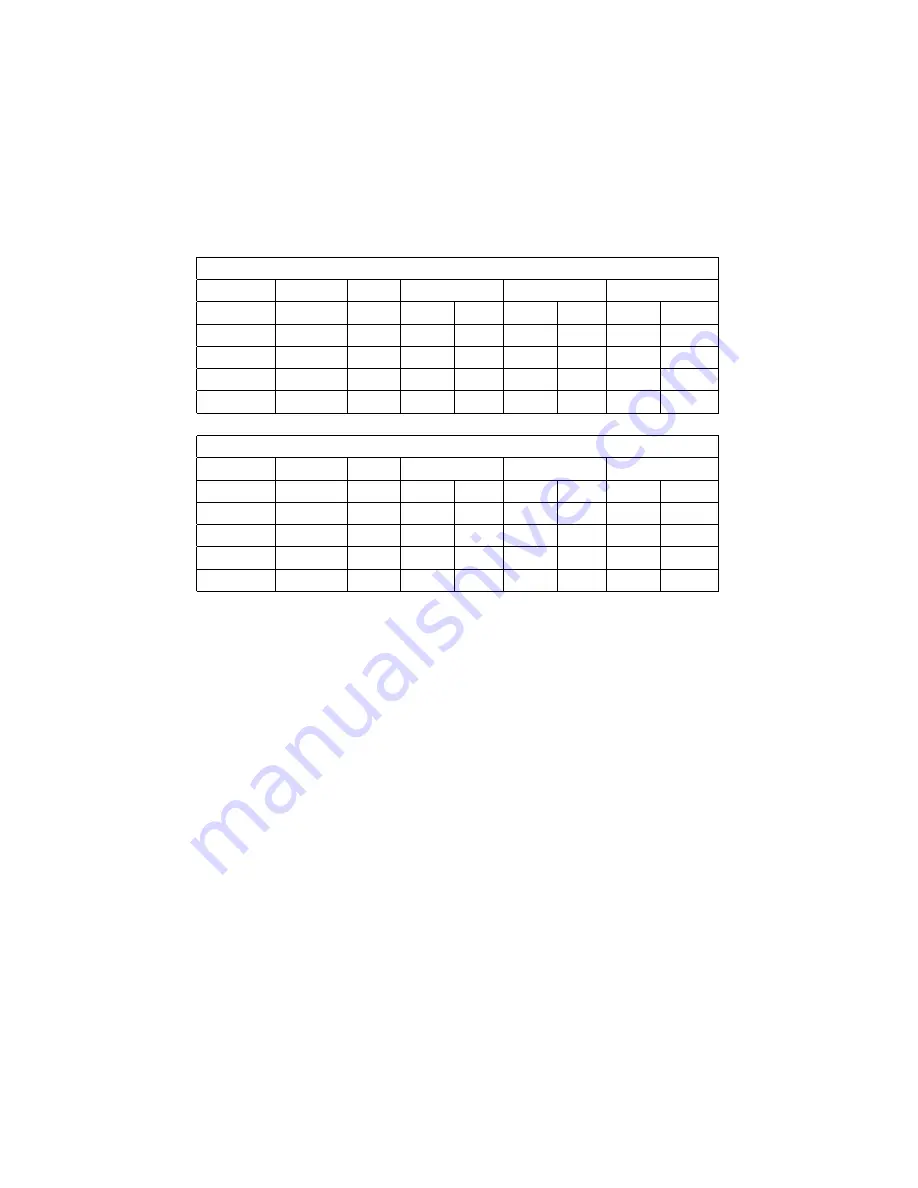

Table 3.4: IC-13 Packaged and Unpackaged Dimensions

Packaged Dimensions

Model

Metric

US

IC-1355

IC-1363

IC-1379

Width

mm

in

2340

92.1

2340

92.1

2780

109.4

Depth

mm

in

770

30.3

770

30.3

770

30.3

Height

mm

in

1400

55.1

1400

55.1

1400

43.6

Weight

kg

lbs

335

737

375

825

435

957

Volume

cu m

cu ft

2.52

89.0

2.52

89.0

3

105.9

Ironer Dimensions

Model

Metric

US

IC-1355

IC-1363

IC-1379

Width

mm

in

1960

77.2

2210

87.0

2630

103.5

Depth

mm

in

644

25.4

644

25.4

644

25.4

Height

mm

in

1107

43.6

1107

43.6

1107

55.1

Weight

kg

lbs

300

660

355

781

428

942

Volume

cu m

cu ft

1.4

49.4

1.58

55.8

1.83

64.6

3.8

Room Requirements

The ironer must be installed in a well-ventilated room (particularly when using gas heating) with

correct lighting and an ambient temperature not exc10

◦

C to +40

◦

C / 50

◦

F to 105

◦

F

(temperature limits for the AC drive for the main motor). Below +10

◦

C/50

◦

F, the temperature

sensor will not work and the control panel will display an alarm (AL7).

Sufficient space must be provided around the ironer to allow for correct operation:

1. 5-10cm (10-12in) minimum at the back to allow for ventilation.

2. 60-80cm (24-32in) on each side to allow for servicing and maintenance.

3. Sufficient space must be provided at the front of the ironer to allow the operator to work

correctly and safely.

Leveling should be carried out on a hard and stable floor that can support the significant weight

of the ironer (400 to 500kg on 1.6 to 2 m

2

or 880-1100 lbs on 18-22 ft

2

).

The installation of this ironer requires a floor that can support a minimum of 500kg per m

2

or 50

lbs per ft

2

.

14