Revision 3 May 2010

2.0 INSTALLATION

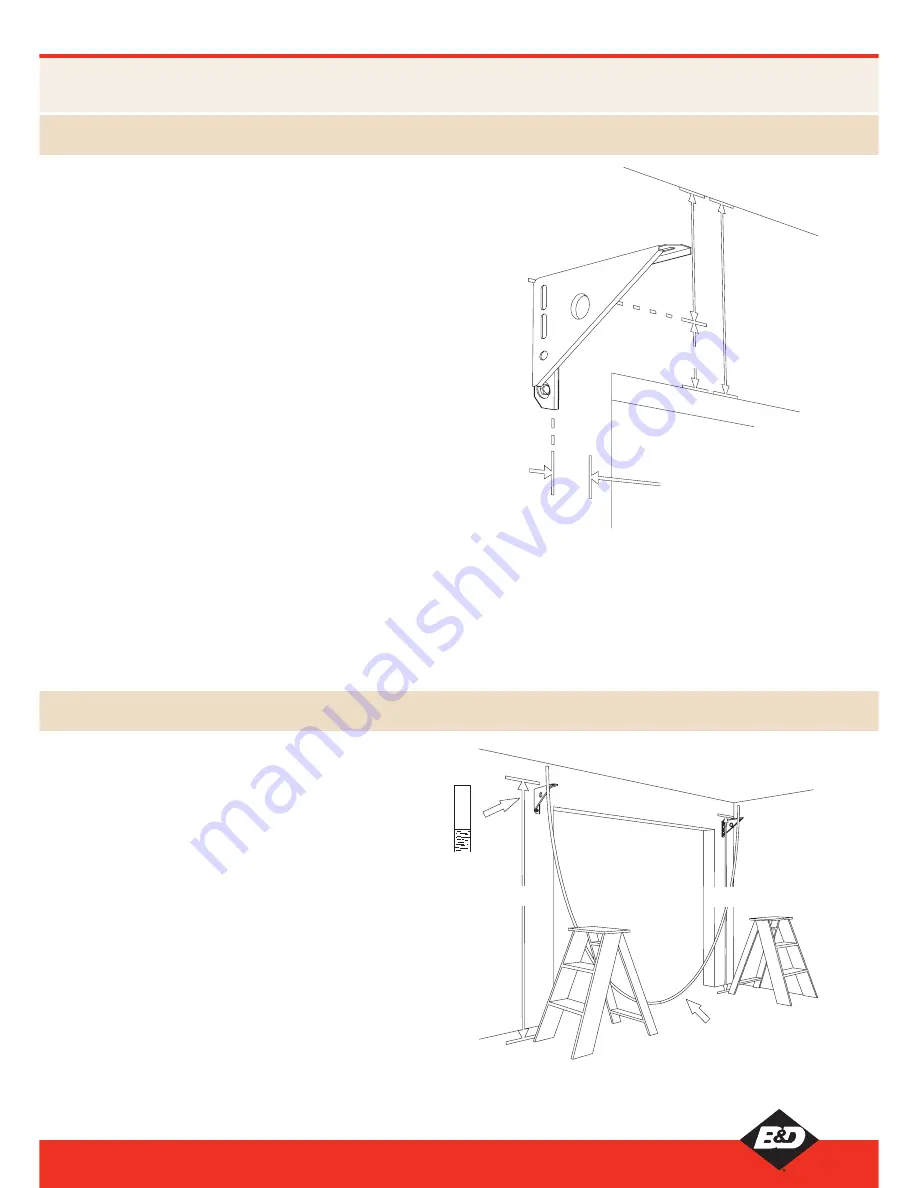

2.1 INSTALL FIRST BRACKET

a) Measure the door curtain width and mark where edge of the curtain will

be, allowing for over lap on each side of the opening.

b) Add clearance of 10 to 75mm from edge of curtain to inside edge

of bracket to determine positioning of the bracket. Also check this

clearance if an opener is being fi tted.

c)

Normal Headroom

(350mm for doors up to 2200mm high, 370mm for

doors over 2200mm high). Measure up 120mm from underside of the

head. If the head is not level, measure up from the lowest side fi rst.

Restricted Headroom

(315mm for doors up to 2200mm high, 335mm

for doors over 2200mm high). Measure down 230mm (or 250mm if

door is over 2200mm high) from roof or lowest obstruction to the top of

the bracket. (Bracket should be between 85mm and 100mm up from

the lintel).

If less headroom than shown above or no headroom is available

, follow

the restricted headroom instructions and for appearance purposes fi t a

false head if necessary.

d) Mark two hole positions using top and bottoms lots of the bracket.

e) Drill both holes, then attach bracket using the 50mm x 10mm coach

screws and washers supplied (or masonry anchors if fi xing to brickwork).

120mm

10 -

75m

m

Line for Edge of Door Curtain

(Check this measurement if an

opener is to be fitted)

230mm Restricted or

250mm Normal Headroom

315mm Restricted or

350mm Normal

2.2 INSTALL SECOND BRACKET

EQUAL

WATER LEVEL

EQUAL

HOSE

a) Using a water level mark the position for the second

bracket.

NOTE:

The brackets must be perfectly level

for the door to operate.

b) Re-check levels then drill and fi x as with fi rst bracket.

5

Roll-A-Door

®

Series 1 Installation Instructions