• Do not pressurize above 50 psi.

• Do not adjust the tip or change spray patterns while

depressing the valve lever or atomizing cap.

• Open cap slowly to release air before removing;

keep bottle upright when releasing pressure.

• Do not store for long periods or transport the unit while

bottle is pressurized.

• Do not use plastic bottle if there is any signs of damage.

• Inspect the plastic bottle, coiled hose, tank gasket,

discharge valves, and nozzle for signs of wear or

damage. These parts must be in full working condition

to permit pressurization of the bottle.

Mixing and Filling

• Mix insecticides for the Professional ACCU-Spray in a

separate container and then add 16 oz. to the bottle.

• When mixing insecticides for the standard ACCU-Spray

(plastic bottle), note the 16 oz. (473 ml) mark on the side

and mix insecticide accordingly.

• Follow all label directions when mixing insecticides.

• Add only 16 oz. (473 ml) of liquid to the bottle to maintain

proper head space for air pressure.

Pressurizing the Bottle

• Pump plunger up and down 8-10 times until there is pres-

sure against the plunger; do not over-pressurize.

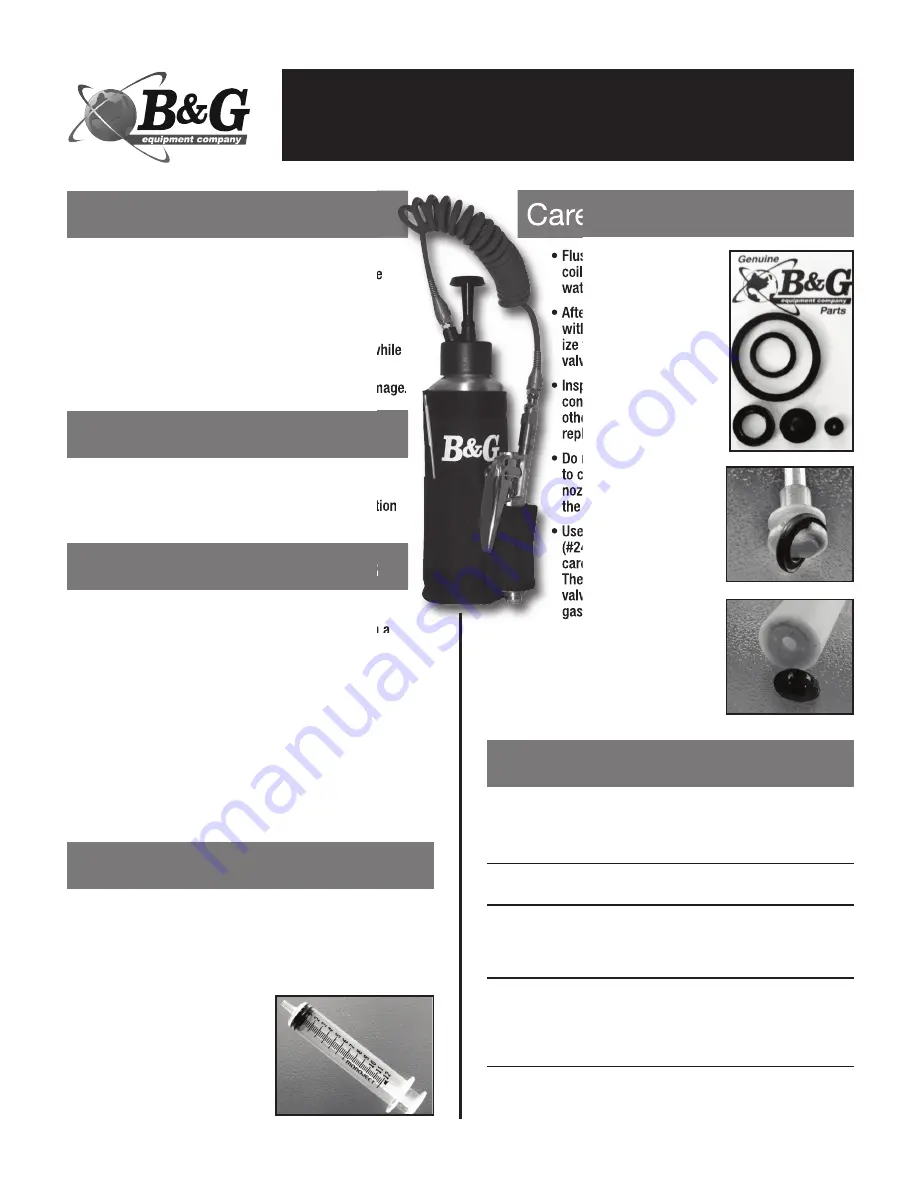

ACCU-Spray comes with a syringe for mixing the correct

amount of insecticide in the bottle.

The syringe is marked in milliliters. The intended use of the

syringe is for the tip to be inserted into the reservoir of a tip-

n-pour bottle, and to draw up insecticide concentrate.

• Insecticide amounts for 16 oz.:

Phantom™ = 8.9 ml

Talstar™ = 1.2 or 3.7 ml

Suspend™ = 2.8 or 5.5 ml

Tempo SC™ = 2.0 ml

Demand CS™ = 1.5 or 3.0 ml

Kicker™ = 7.8 or 15.6 ml

• Flush bottle, valve, and

coiled hose with clean

water regularly.

• After rinsing the bottle

with clean water, pressur-

ize the unit and flush the

valve and hose.

• Inspect hoses and hose

connections, gaskets, and

other fittings for wear;

replace when necessary.

• Do not use metal objects

to clean the orifices in the

nozzle, this will disrupt

the liquid spray pattern.

• Use B&G Repair Kit

(#24000037) for regular

care and maintenance.

The Kit includes a check

valve, pump tube plunger

gasket, and a cap gasket.

Safety Precautions

Trouble Shooting

Care and Maintenance

Operating Instructions

Calibration Syringe

Before Starting

ACCU-SPRAY

USER’S MANUAL

Problem:

Bottle not holding pressure, air leaks from top

of bottle.

Solution: •

Tighten cap

• Replace cap gasket

Problem:

Bottle not getting air pressure

Solution:

Replace pump tube plunger gasket

Problem:

Pump tube fills with water when pumping

Solution:

• Clean around the check valve at the bottom

of the tube

• Replace the check valve

Problem:

Holds pressure, but will not spray; spray is weak

or sputtering

Solution:

• Nozzle clogged, clean with a soft brush

• Siphon tube clogged, clean end

• Clean strainer at the hose/valve junction

Problem:

Valve body leaking

Solution:

Tighten packing nut, replace packing washers

(in GD-124 Repair Kit)

• Replacing the pump tube plunger

gasket requires stretching the gasket

over the end of the tip.

• Remove and clean around the check

valve at the tip of the pump tube.

95138474 Rev 2/10