TECHNICAL INFORMATION

TRACK MAINTENANCE

The components of the under carriage are open to soil, sand, rock, water, chemicals and the

elements because of functional necessity. Regular maintenance of the undercarriage is

inevitable. Compensation though, is that the components are readily visible for inspection.

DESIGN CONSIDERATIONS

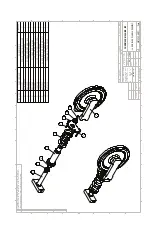

Many items must be considered and engineered for a track drive unit. Some of them are:

1. Track length, width and pitch

2. Shoe width (no wider than necessary is best)

3. Track design required for machine gross weight and pull

4. Track tensioner design based on application and machine gross weight

PRECAUTIONS/HANDLING RECOMMENDATIONS

Installation and Repair

Only trained personnel should preform the mounting of rubber tracks. Incorrect assembly

may result in premature failure and/or damage to the machine.

Tension of Rubber Tracks

Improper tension may result in track alignment problems, detracking and is a major

contributor to premature failure. Tension should be inspected regularly and adjusted if

necessary. See maintenance section.

Loose tracks can allow excessive machine motion resulting in decreased

stability during operation.

Unfavorable Terrain Conditions

Rubber tracks should not be used in certain terrains, because damage can occur to the lug

sides of the tracks. Some common and unfavorable terrain conditions are: hard surface

roads, rocky fields, stump fields, large ruts or holes, scrap rebar, troughs, crowned ridges

and along walls or border stones. Inspect the work site before beginning operation and

remove any of these items when possible.

Page 10

Technical Information