ADJUSTMENTS

Inspect Tension

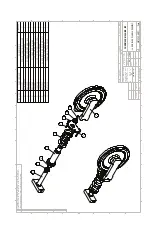

Check the tension at the center track roller every 10 to 15 hours of work. See figure 8.

Tension should is by measuring the slack between the track rollers and inside of the track.

When correctly adjusted, this slack should be 0.60-0.75 inches. The spring loaded tensioner

in the track unit is engineered by Chermack Machine, Inc. to tension the track in proportion to

the gross machine weight as required for construction, agricultural and snowfield machinery

when the measured slack is as specified.

Adjust Tension

1. Remove the protective cap from the grease valve. See figure 9.

2. Support track assembly so the track clears the ground.

3. Apply a standard grease gun to the grease valve fitting (zerk) and slowly pump grease

to extend the track tensioner against the compression spring. Continue to pump grease

until the track slack is 0.60-0.75 inches as shown in figure 8.

4. The grease valve has a check valve behind the zerk to prevent grease from coming

back under pressure. If it is necessary to release track tension, turn the check valve

CCW one half turn and allow grease to expel. Retighten when complete.

5. Lower the track back onto the ground and replace the protective cap.

Maintenance

Page 15

FIGURE 8.

TENSION OF RUBBER TRACK

0.60-0.75 in.

[15-2- mm