CLEANING

Keep driving system cleaned and

properly maintained. Remove any

debris or mud which could interfere

with the operation of the machine.

If mud and debris is allowed in the

under carriage it can plug the

spring loaded tensioner preventing

it from relieving stress on the track

when traveling over irregular

surfaces. Mud can build up on the

track rollers thereby over

tensioning and stretching the track

or the rollers can stop turning and

then scrub on the track creating

wear and failure.

Wash fuel and oil from the tracks.

REPAIR

In order to prevent bonding or corrosion failures, tracks should be repaired immediately when

damaged.

Minor cracks in the rubber can be filled with rubber repair compound.

Once the steel cords have failed, the track is no longer serviceable.

Page 16

Maintenance

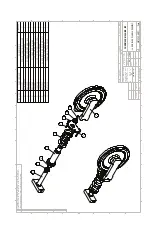

FIGURE 9.

TIGHTENER ADJUSTMENT

PROTECTIVE CAP

GREASE VALVE FITTING

CHECK VALVE

COMPRESSION SPRING