Bandit

91

Copyright 9/18

MODEL 15XP/1390

HYDRAULIC PUMP CHECK OUT

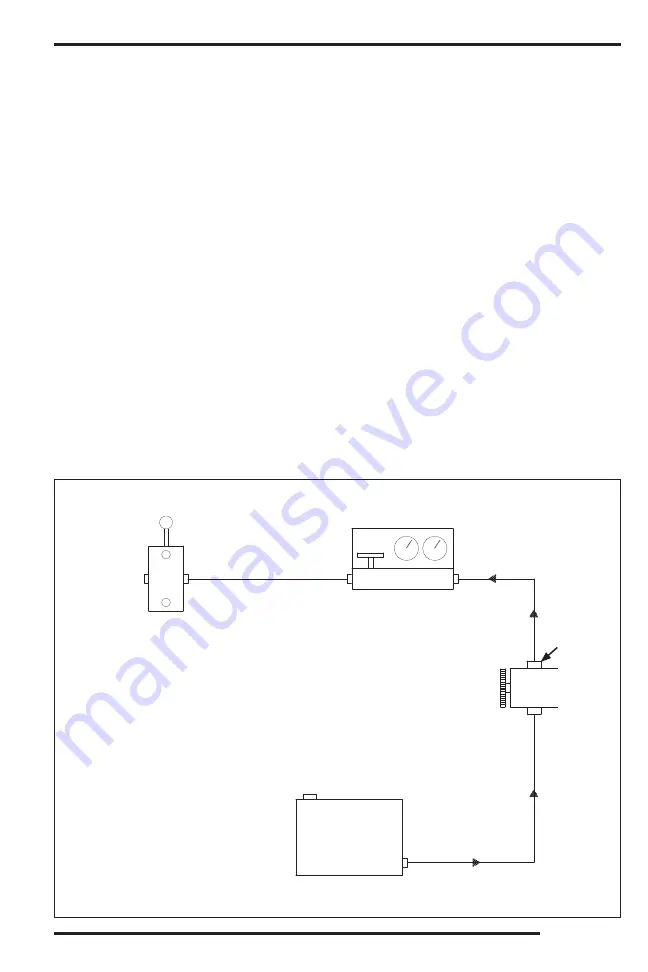

HYDRAULIC PUMP CHECK OUT USING A FLOW METER (WITH RELIEF)

To check out the hydraulic pump the mechanic will need a needle type fl ow meter capable of reading 3000

psi (207 bar) and a long enough hose that will go from the fl ow meter back to the fi rst component.

1.

Disconnect the pressure line going from the pump at the fi rst component.

2.

Attach the fl ow meter to the end of the pressure hose (which was removed from the component).

3.

Attach the hose you supplied to the outlet of the fl ow meter and run the hose back to the fi rst component.

MAKE SURE THE HOSES ARE ON THE CORRECT SIDES OF THE FLOW METER.

4.

Make sure the pressure gauge is installed up stream from the fl ow control valve. Failure to do

this will cause serious damage to the hydraulic pump when testing.

5.

MAKE SURE THAT THE FLOW CONTROL VALVE IS FULLY OPEN SO AS TO ALLOW

UNRESTRICTED FLOW TO PASS THROUGH IT.

6. Start the engine to engage the pump, the clutch may have to be engaged if the pump is belt driven.

7.

Observe the fl ow rate through the meter and pressure gauge reading to make sure a high pressure

does not exist.

8.

Increase the engine speed slowly to full rpm and at the same time observe the pressure and fl ow rate.

The pressure should still remain low. Make a note of the fl ow rate (gpm or Lpm) at full engine rpm.

9.

SLOWLY

turn the needle valve on the fl ow control in and observe the pressure increase on the pressure

gauge.

10.

Continue closing the fl ow control valve until the pressure gauge reading reaches 90% of the normal

relief valve setting (example: if system runs at 2500 psi (172 bar), do not exceed 2250 psi (155 bar).

Never allow the pressure to go more than 90% of the main relief pressure.

11.

If the pump is good, you should have at least 80% of the fl ow rate (gpm or Lpm) passing through the

fl ow meter as noted at low pressure and full rpm (example: 10 gpm (38 Lpm) and low pressure = 8 gpm

(30 Lpm) at 90% pressure).

12.

If 90% of the main relief pressure can not be obtained and/or the fl ow rate passing through the meter is

considerably less, then the pump is worn or damaged.

Do not exceed

90% of system

pressure.

First

component

after pump.

Flow

Direction

Hydraulic

Tank

Flow Meter

(with relief)

Pump

Outlet

Hose

supplied by

you.

Flow

Direction

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

HYDRAULICS