02

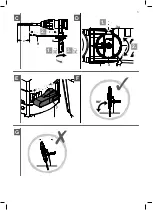

Auxiliary handle (Fig. A)

WARNING!

For all work with the machine, the auxiliary handle (2) must

always be mounted.

Do not make any changes or modifications to the auxiliary handle.

Do not continue to use the power tool when the auxiliary handle is

damaged.

1. Turn the auxiliary handle (2) anti-clockwise to loosen it.

2. Adjust the auxiliary handle to appropriate position depending on your application.

3. Turn the auxiliary handle clockwise to clamp it on the spindle collar firmly.

03

Drill bit / chisel (Fig. B)

WARNING!

• Observe the technical requirements of this product (see section

Technical data) when purchasing and using drill bits!

• The chuck and drill bits can be very hot after working, do not

assemble/disassemble them before cooling down!

1. Clean and lightly grease the shank end of the SDS-Plus drill bit.

2. Pull the chuck sleeve (2) backward and hold it in position.

3. Insert the SDS-Plus drill bit/chisel. To insert it completely until stop, combine the

inserting and rotational motion and find the proper position.

4. Release the chuck sleeve (2) and check that the drill bit/chisel is securely fas-

tened. The drill bit/chisel should be locked in the chuck and shall not be possible

to be pulled out.

5. To remove drill bit/chisel, pull the chuck sleeve (2) backward and pull it out.

04

Depth stop (Fig. C)

1. Loosen the auxiliary handle (8) by turning anti-clockwise and insert the depth stop

(9) through the hole as indicated. The depth stop should be turned to a radial po-

sition so that the tips of drill bit and depth stop have the smallest radial distance.

2. Align the tip of the depth stop (9) the drill bit tip in axial direction and then pull the

depth stop back to achieve the desired drilling depth “X”.

16