SAFETY WARNINGS FOR ROTARY HAMMER

a)

Wear ear protectors.

Exposure to noise can cause hearing loss.

b)

Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause

personal injury.

c)

Hold power tool by insulated gripping surfaces only, when performing an

operation where the cutting accessory may contact hidden wiring or its

own cord.

Cutting accessory contacting a “live” wire may make exposed metal

parts of the power tool “live” and could give the operator an electric shock.

d) When drilling it is common that the core / drill bit jams in the material being

drilled. This will result in the drill trying to rotate around the drill bit and

potentially come out of your grip. This SDS Drill has a safety clutch mechanism.

This safety clutch mechanism will be activated and stop the drive to the drill

bit BUT only if you resist the initial forces caused by the jamming by securely

holding the drill with both hands. As this is a very powerful drill these forces are

significant.

e) ALWAYS ensure that the front handle is firmly affixed and secure.

f) The Front and rear handle must be firmly held to resist any movement of the

drill when the core drill or drill bit becomes jammed.

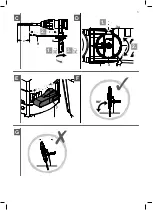

g) ALWAYS use this drill when standing on a firm and secure platform or the

ground. (DO NOT USE ON LADDERS OR STEPS)

h) NEVER Start the Drill with the core or drill jammed in position.

i) DO NOT stretch to hold the drill. Do not drill above shoulder height or below

Knee height, as the drill cannot be securely held.

j) Never drill holes that are above the declared maximum size in the manual.

k) This drill is not designed for core drilling above the maximum drilling capacity

in masonry.

l) The power tool shall not be wet or applied in wet environment.

m) The voltage of the power source must agree with the voltage specified on the

nameplate of the machine.

n) Check the product, its power cord and plug as well as accessories for damage

before each use. Do not use the product if it is damaged or shows wear.

o)

Double check that the accessories and attachments are properly fixed.

A short-time testing running in no-load condition will be helpful to identify the

problems.

p)

Use suitable detectors to determine if utility lines are hidden in the work

area or call the local utility company for assistance.

Contact with electric

lines can lead to fire and electric shock. Damaging a gas line can lead to

explosion. Penetrating a water line causes property damage or may cause an

electric shock.

q)

Secure the workpiece.

A workpiece clamped with clamping devices or in a

vice is held more secure than by hand.

r)

Keep the handles dry to ensure safe control.

Grip the product securely with

two hands so you have full control at all times.

s)

The drill bit, chuck and the work piece can be very hot while working.

Do

not touch them before they have cooled down.

t) Ensure that the air vents are always unobstructed and clear. Clean them if

necessary with a soft brush. Blocked air vents may lead to overheating and

damage the product.

8