X20 system modules • Other functions • X20CM4810

X20 system User's Manual 3.10

2079

•

Sufficient warning time must be given in advance before a function fails.

The consideration of the condition monitoring "tool" must not only be limited to the recognition of operating condi-

tions, but should be integrated into the general asset management strategy as a component of this. In order to man-

age this, all types of condition monitoring and industrial diagnostics should be integrated into an overall strategy.

For a failure-oriented operational mode ("reactive maintenance"), components are only replaced if they can no

longer fulfill their function. For a planned operational mode ("preventive maintenance"), components are replaced

at a certain point in time – regardless of their current condition.

For state-oriented maintenance, the area where maintenance is planned can be significantly isolated while reducing

the risk of failure at the same time.

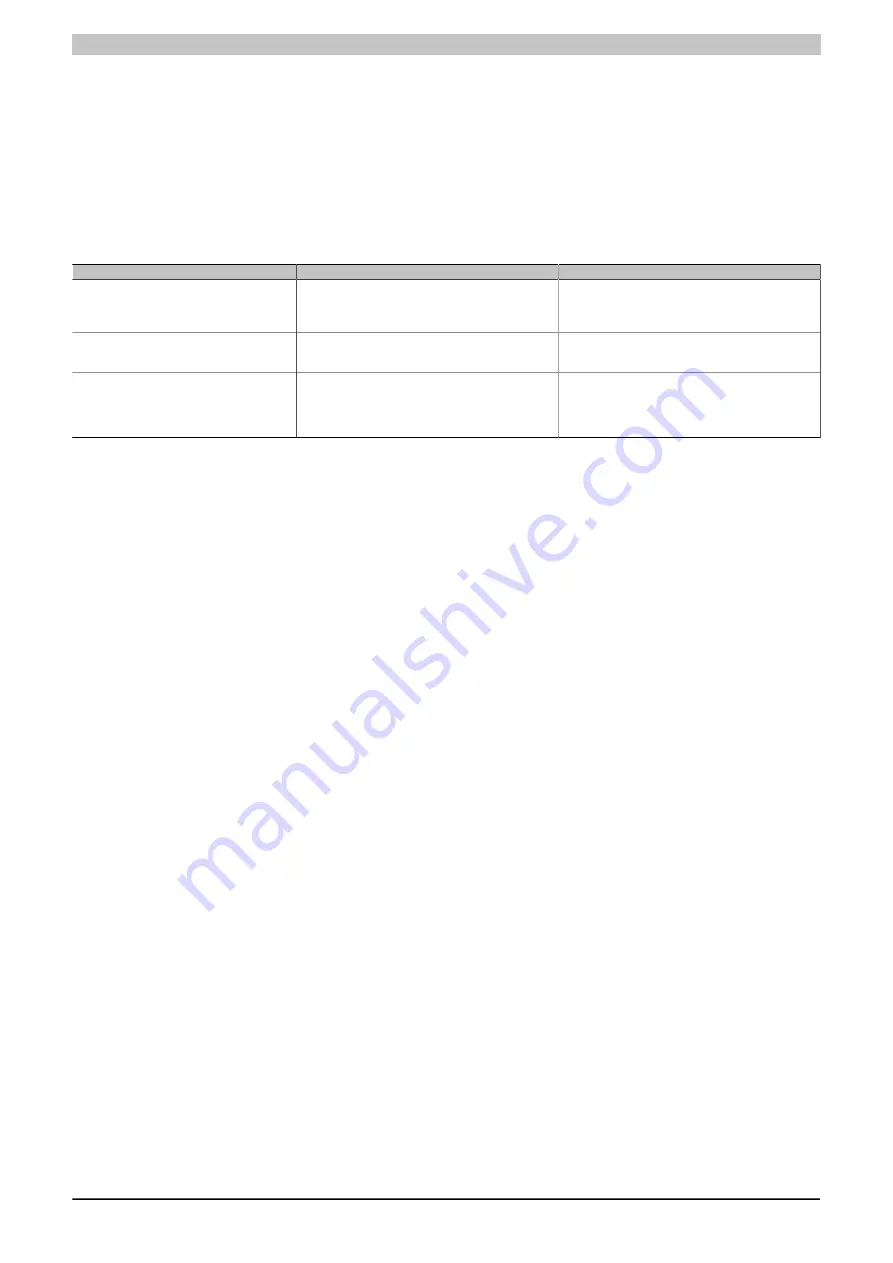

Advantages

Disadvantages

Reactive maintenance

- Utilization of the wear reserve

- No costs during the period of use

- Unexpected failure

- Consequential damage

- High downtime costs

- Low operational safety

Preventive maintenance

- Can be planned well

- No utilization of the wear reserve

- Increased risk of failure after maintenance

- Repair costs

State-oriented maintenance

- Early recognition of problems

- Downtime can be planned

- Utilization of the wear reserve

- High operational safety

- Avoidance of consequential damage

- Dealing with the issue

- Investment costs

Table 727: Comparison of the advantages and disadvantages of standard maintenance strategies

4.26.2.4.1.2 Conventional condition monitoring

•

There exists a lot of measurement and process data that is not currently used for condition monitoring (CM).

Links and correlations with process parameters and further CM parameters can often be made possible

only with considerable expenditure.

•

CM systems are implemented as "isolated applications". In such cases condition monitoring is performed

by standalone sensor and measurement systems with standalone hardware and software

•

The range of different systems can lead to significant problems in the on-site operation of the system.

Different software solutions make it more difficult since there is separate hardware and a separate user

interface for each CM method and each CM tool.

•

In many cases, necessary expert knowledge specific to a system is not available. The complexity of some

configuration tools exceeds the user's existing expertise.

Using the X20CM4810 together with B&R standard modules has the following advantages:

•

Easy exchange of process data and condition monitoring data

•

Easy integration of parameters in the overall process

•

Modular construction

Summary of Contents for X20 System

Page 2: ......