X90 mobile modules

X90 mobile system User's manual V 1.20 - Translation of the original manual

239

If a fixed medium is stimulated by an impact, structure-borne sound spreads throughout it. This consists of additional

frequencies which are determined by the shape of the structure and the material it is made from (e.g. gong or

concrete block).

A portion of the structure-borne sound energy is converted into airborne sound through the surrounding atmos-

phere.

Structure-borne sound

Airborne

sound

Figure 69: Propagation of structure-borne sound

The measurement and subsequent analysis of the mechanical oscillations on stationary and rotating parts of ma-

chines, support structures and pipelines has become accepted as technically possible with practically applicable

monitoring procedures.

The absolute bearing oscillation is measured on the housing of the machine and involves the movements of the

housing in relation to a fixed reference point in the room.

Mechanical oscillations are a good parameter for detecting initial defects and damage and can be used for machine

diagnostics.

There are numerous overlapping causes for oscillations. The size (amplitude) of the oscillation depends on several

factors such as attenuation through joints or grease, the rigidity of the component, the housing and foundations

and much more.

Damage is always a consequence of stress. If cyclic stress occur, it can be identified by its excitation frequency

and intensity.

Resonant frequency

Every machine has what are known as resonant frequencies. These must be observed during operation since

with these frequencies the amplitude of the oscillation increases dramatically, putting strain on the mechanical

components. If harmonic oscillations occur for a long time in proximity to the resonant frequency, this can lead to

a so-called "resonance catastrophe", which causes the destruction of the affected part.

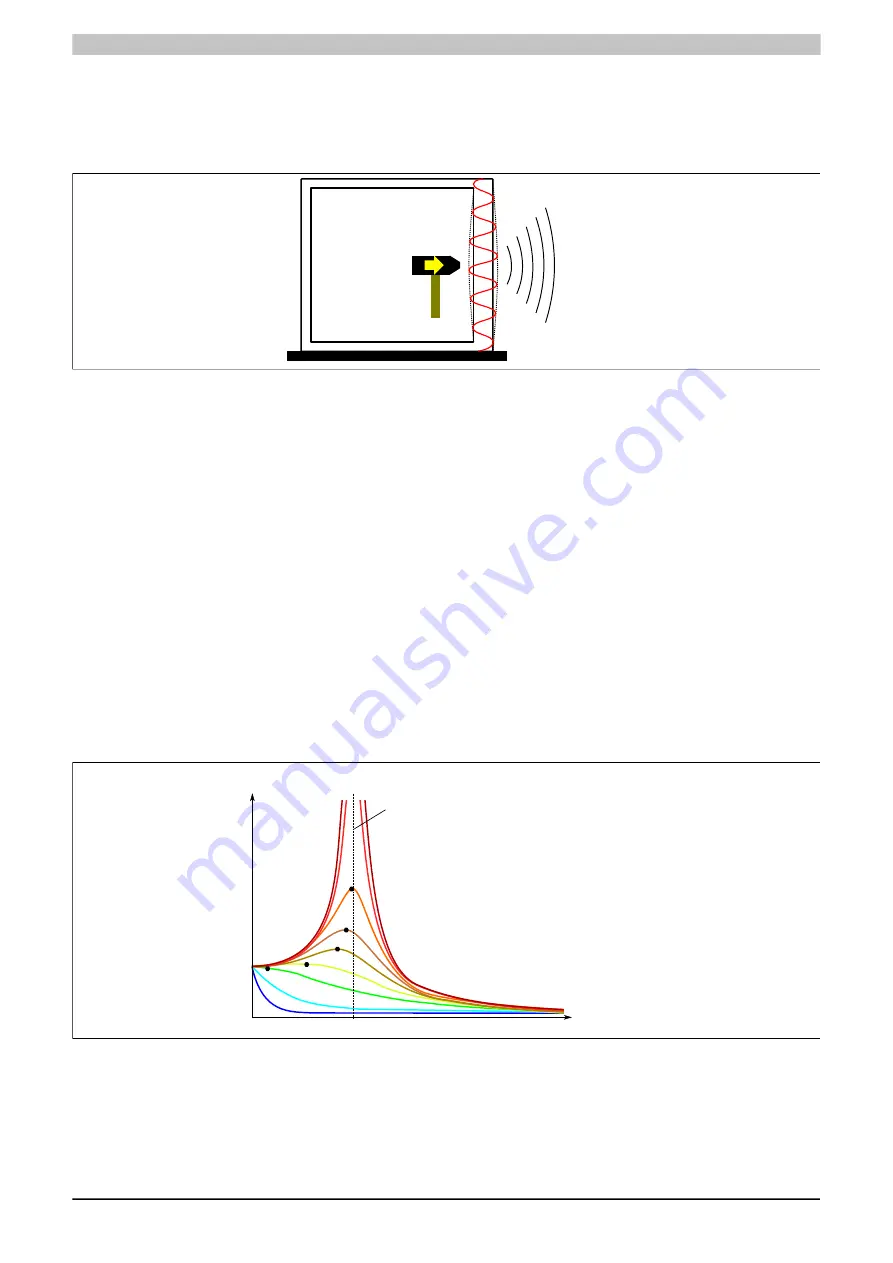

Amplitude

(ω)

ω

0

Resonant frequency

Frequency

Figure 70: Increase of the amplitude in proximity to the resonant frequency