L 900 Series Oven Range (AGA No. 4921-07)

April 2011

11

F

IGURE

2:

C

ONTROL

P

ANEL

–

B

OILING

/

C

OOKTOP

S

ECTION

F

IGURE

3:

C

ONTROL

P

ANEL

–

O

VEN

S

ECTION

L

IGHTING

I

NSTRUCTIONS

Boiling Top Burners - Models with Pilot and/or Flame Failure

1.

Ensure the control knob is in the „OFF‟ position. If not, turn control knob clockwise until it is in the „OFF‟

position.

2.

Push knob, and turn knob anti-clockwise to „PILOT‟ position.

3.

Whilst keeping the knob pushed in, light pilot.

4.

Continue to hold the knob for 30 seconds after the flame appears on the plot. Release the knob. The

pilot should remain lit.

If pilot fails to remain lit, push down the control knob and turn

clockwise to the ‘OFF’ position. Wait for five minutes before attempting to re-light (repeat

steps 1-4).

5.

Once pilot is lit, push down and slowly turn the knob anti-clockwise to the „HIGH‟ position.

6.

Adjust the size of the flame as required by turning knob anti-clockwise.

7.

To turn burner off whilst keeping pilot lit, turn knob clockwise to the „PILOT‟ position.

Boiling Top Burners - Models without flame failure

1.

Ensure the control knob is in the „OFF‟ position. If not, turn control knob clockwise until it is in the „OFF‟

position.

NOTE:

Do not allow a period greater than 5 seconds to elapse between steps 2-3 for the following

instructions.

2.

Push knob, and turn knob anti-clockwise to „LOW‟ position.

3.

Whilst keeping the knob pushed in, light burner.

If burner fails to light, push down the control

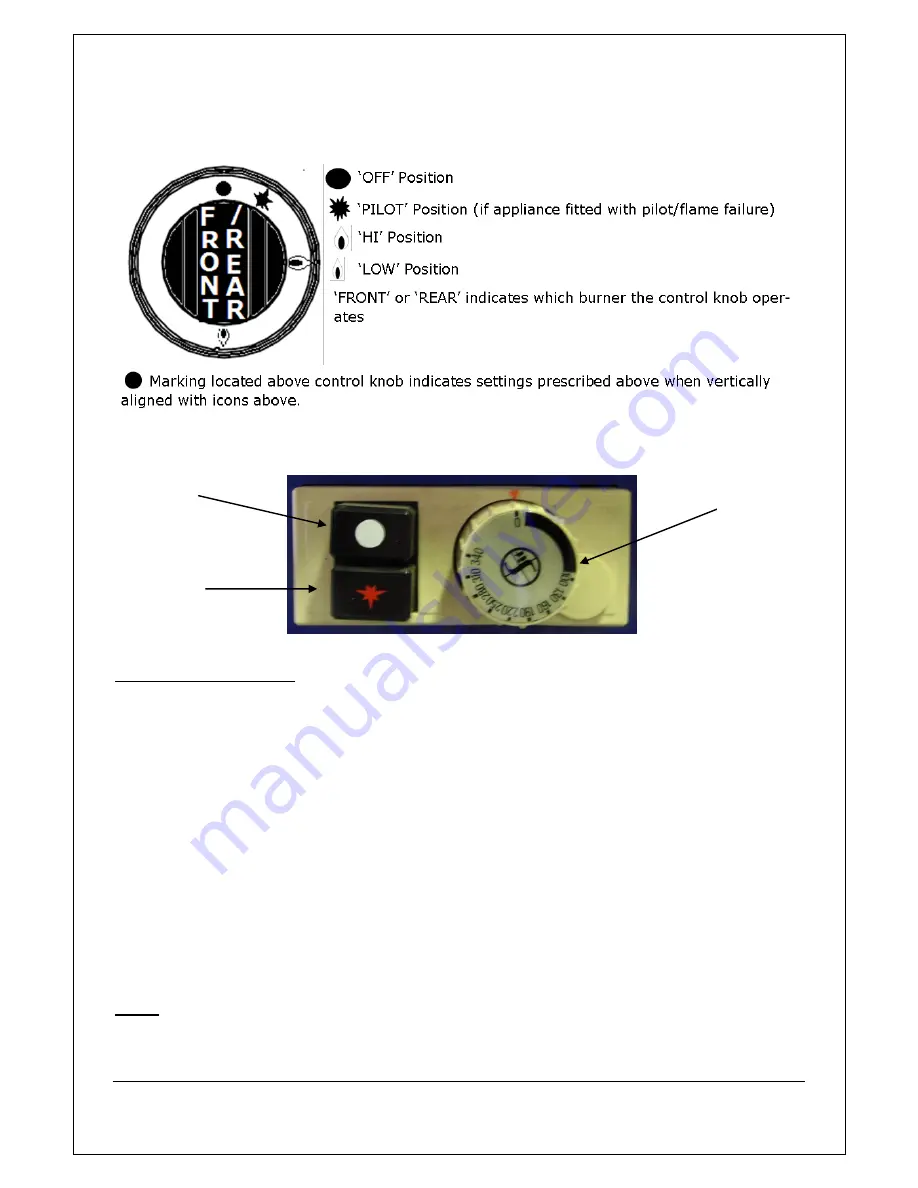

Pilot

Extinguish

Button

Pilot

Ignition

Button

Temperature

Control Knob