27

OPTIFORMA Frame Heater 2872 01/22

9

Problems and solutions

In the following chapter possible causes for faults and work needed for their

resolution are described.

For problems and faults that cannot be resolved using the following instructions,

contact your authorised dealer or the manufacturer. For Germany see the ser-

vice address on page 2.

9.1 Troubleshooting guide

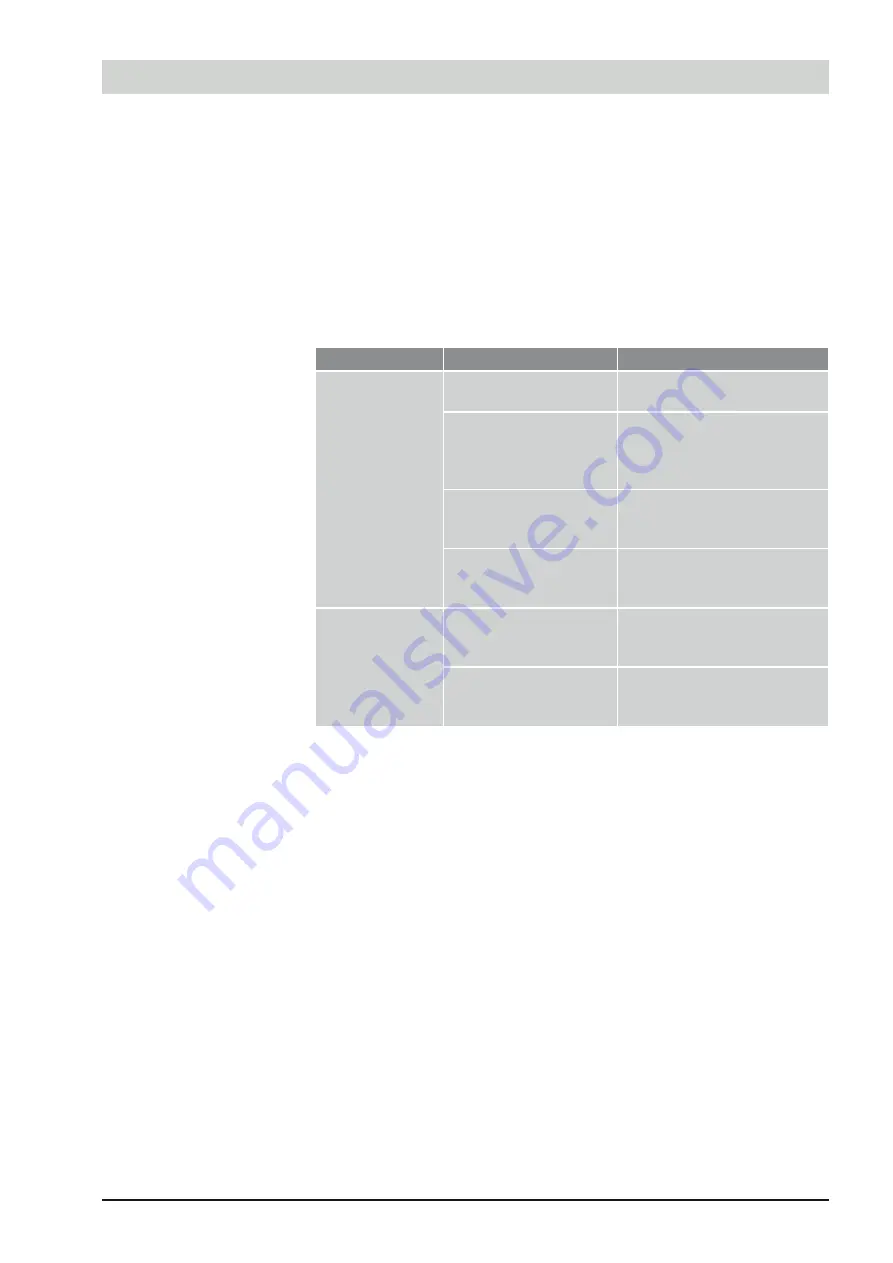

Personnel: Specialized personnel

Fault description

Cause

Remedy

Frame heater

does not function

Power failure

Check the fuse of the power

supply.

Instrument not connec-

ted to the power supply

Connect to the power supply

(Chapter 6.3 ‘Connect the

unit to the power supply’ on

page19).

Instrument is switched

off

Switch on the device (Chapter

7.2 ‘Switching on the instru-

ment’ on page 20).

Tilt switch has been trig-

gered/instrument is tilted

too far

Level instrument.

Temperature not

high enough to

heat the plastic

part of the optical

frame

Temperature is set too

low

Increase the temperature (Ä

Chapter 7.3 ‘Adjust the tempe-

rature’ on page 21).

Time for heating is set

too short

Increase the time for heating

(Chapter 7.4 ‘Adjust the time’

on page 21).

Problems and solutions