BANLAW PRODUCT DATA SHEET

DRY-BREAK DIESEL REFUELLING NOZZLES

Doc ID: PRH-REF-70 Version: 7.0

Page

19

of

32

Please ensure you have the latest version of this document.

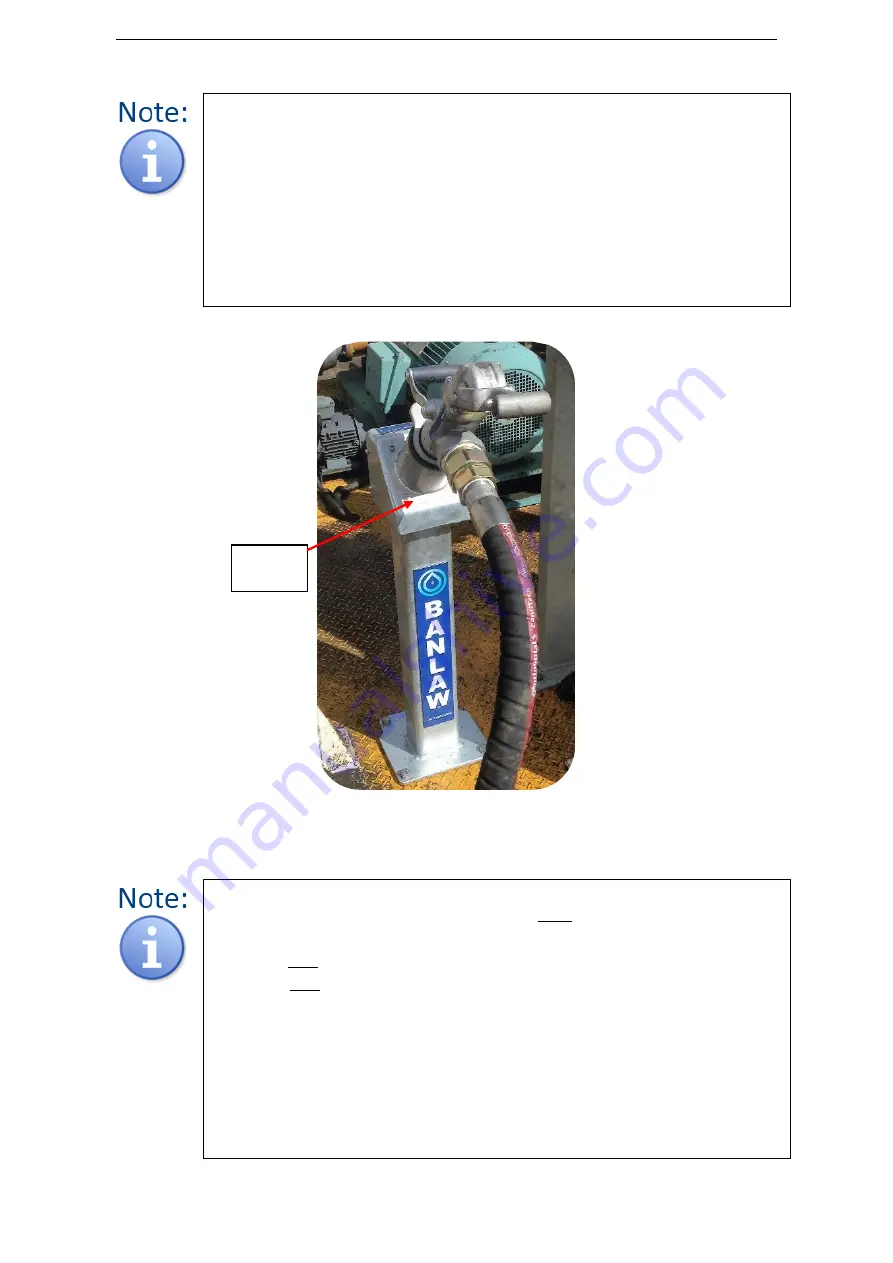

Figure 18 - Nozzle Stored in Nozzle Holster

4.2

Installation Guidelines

A dedicated means of securely storing a Nozzle off the ground provides several key

benefits, including;

•

Minimises the ingress of contamination (dust, water, etc.) into the Nozzle -

maximising the service life of the Nozzle.

•

Minimises the risk of the Nozzle being struck or run over by vehicles in the

same area. Bollards or barriers around the area will also assist.

•

Minimises trip hazards.

•

Can be interlocked with additional safety features to prevent vehicle

“

d

riveaway”.

General Installation Notes;

1.

Conduct a

Job Hazard Analysis

(JHA)

prior

to install to mitigate health,

environmental and equipment hazards.

2.

Do

NOT

install any parts that are damaged or are otherwise faulty.

3.

Do

NOT

install parts which are not compatible with mating parts or parts

which do not satisfy the specifications of the system.

4.

Conduct all necessary measures to

prevent the ingress of contamination

into

the Banlaw Nozzle and other components.

5.

Only engage threads of the same thread type. Ensure all threaded connections

are clean and in good condition. Avoid over-tightening.

6.

An appropriate thread sealant is recommended on the 2” NPT (F) process

connection (inlet) of the Nozzle. Use

sparingly

and avoid excess use of Loctite

NOZZLE

HOLSTER