BANLAW PRODUCT DATA SHEET

DRY-BREAK DIESEL REFUELLING NOZZLES

Doc ID: PRH-REF-70 Version: 7.0

Page

26

of

32

Please ensure you have the latest version of this document.

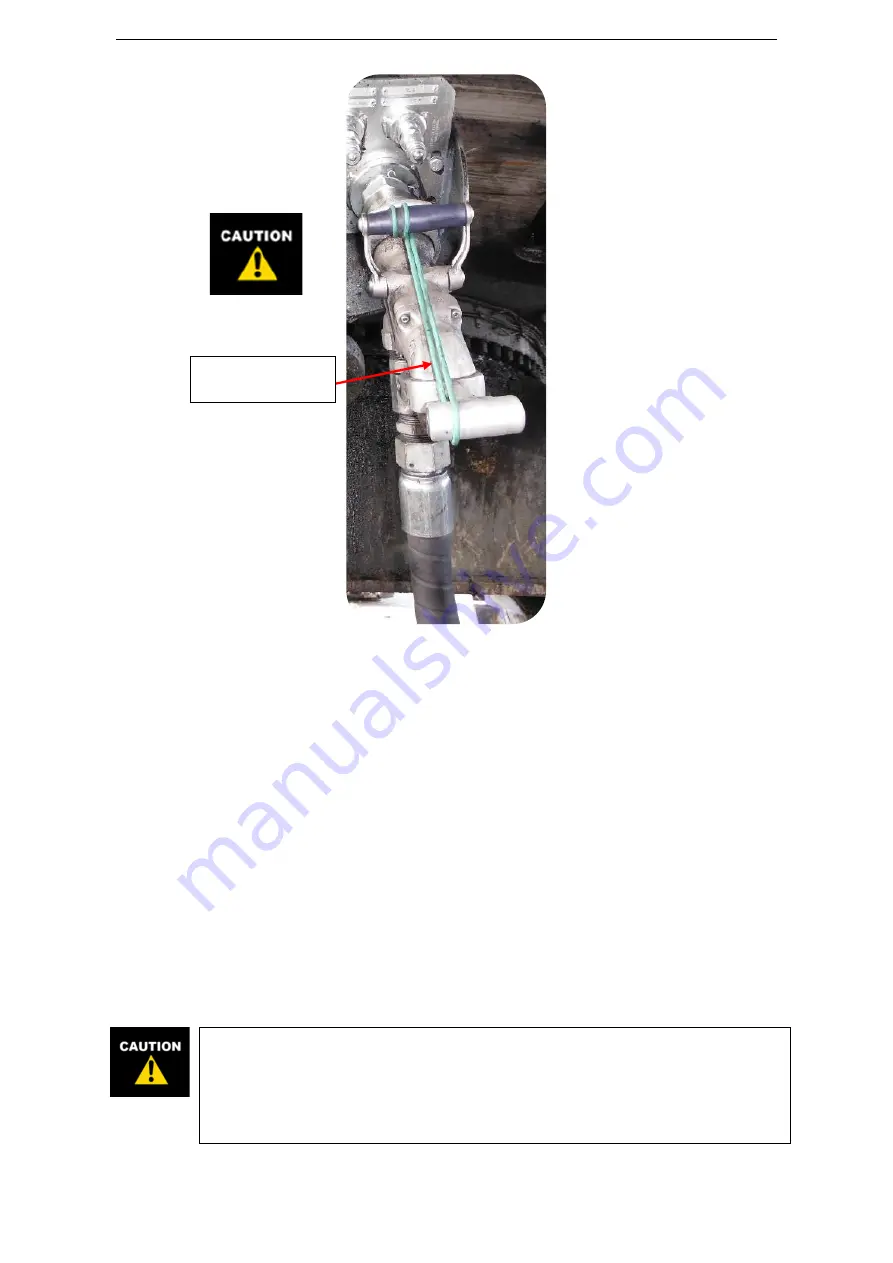

Figure 23 - Nozzle Forcibly Held "ON" (Open)

•

Leakage of fuel from the Nozzle or from between the Nozzle and Receiver.

•

Overfilling of the tank(s), and spillage of fuel to ground via the tank vent(s).

•

Attempting to connect a Nozzle without its operating

(“T”)

handle latched in the OFF (closed)

position

–

operator training required.

•

Personal injury due to poor ergonomics for Nozzle operation, e.g. difficulty connecting the

Nozzle onto the Receiver.

•

The unplanned (uncontrolled) disconnection of the Nozzle from the Receiver

–

i.e. Nozzle “fly

off”.

•

A “drive

-

away”

–

i.e. movement of the plant equipment whilst the Nozzle remains connected.

6

MAINTENANCE & SPARE PARTS

Spare parts (including service kits) for Banlaw Nozzles are only sold to accredited Banlaw nozzle

repairers.

Accredited repairers are required to use only genuine Banlaw spare parts and have been

trained by Banlaw on the safe and proper repair and

testing

of Banlaw Nozzles

–

please refer to the

Banlaw website for a list of repairers near you.

No attempt to repair a Banlaw Nozzle shall be made by untrained personnel.

The

improper repair of a Banlaw Nozzle will create potentially serious health and safety

risks if the Nozzle is used.

The Nozzle incorporates important safety features which

will be jeopardised by improper repair, tampering, adjustment, or modification.

Persons performing such unauthorised activity do so at their own risk.

CORD FORCIBLY

HOLDING NOZZLE “ON”