BANLAW PRODUCT DATA SHEET

DRY-BREAK DIESEL REFUELLING NOZZLES

Doc ID: PRH-REF-70 Version: 7.0

Page

4

of

32

Please ensure you have the latest version of this document.

Hazardous Zone

“An area in which an Explosive Atmosphere is or may expected to be present, in

quantities such as to require special precautions for the construction, installation

and use of equipment.” [AS/NZS 60079.10.1

-2009]. The classification of a

Hazardous Zone is conducted in accordance with the governing Standards

–

typically specific to regions/countries, in the absence of universal (harmonised)

Standards.

Spring Setting

Within this document “spring setting” applies to th

e setting of the automatic shut-

off (closure) feature of a Nozzle. This feature is responsive to liquid (i.e. diesel)

pressure within the Nozzle and can be adjusted by changing the specification of

the Piston Spring within the Nozzle

and/or

the specification of the Poppet Spring

within the Receiver. In simple terms,

increasing

the spring setting will

increase

the

liquid pressure at which the Nozzle will automatically shut-off, and decreasing the

spring setting will decrease the pressure required for shut-off.

1.2

System Overview

Banlaw Dry-Break Diesel Refuelling Nozzles are a key component used in

“quick

-

fill”

refuelling systems.

Banlaw Nozzles provide a means of fuel shut-off and are often used in systems incorporating storage

tank Overfill Protection (e.g. Banlaw FillSafe

™

Zero, FillSafe Power) and fluid asset management systems

(i.e. Banlaw

FuelTrack™

Banlaw

ResTrack™)

.

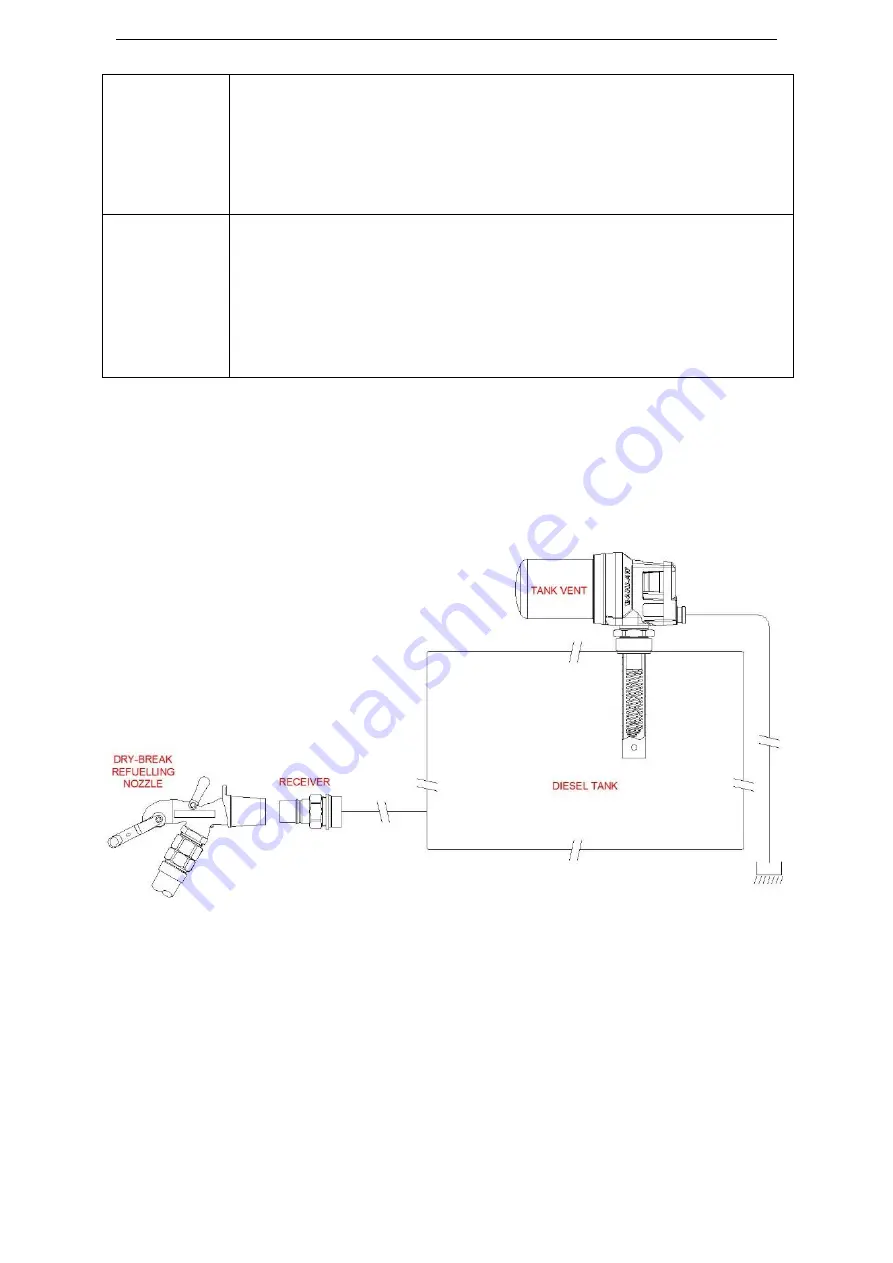

Figure 2

–

Example of a

“

Pressurised Tank

”

Refuelling System

The example shown in Figure 2

is a basic “quick

-

fill” tank refuelling system incorporating Banlaw Nozzle,

Receiver, and Tank Vent. The means of fuel flow shut-off in such systems is by closure of the Vent,

(internal) pressurisation of the tank, and automatic shut-off (closure) of the Nozzle. Incorporating a

Banlaw FuelTrack Receiver provides a means of identifying the unique asset “tag” (code) of the tank

within the FuelTrack or ResTrack system.

The example shown in Figure 3 is a refuelling system using a separate means of tank OFP

–

specifically

a Banlaw FillSafe

™

Zero system. In this example, the

Banlaw “pressurised tank” system acts as a backup

in the unlikely event the primary OFP fails.