2 Specifications and Requirements

2.1 Specifications—Reader

Supply Voltage

10 V dc to 30 V dc

Consumption

0.7 A to 0.2 A maximum

Communication Interface

Main RS232 or RS422 full duplex: 2400 bit/s to 115200 bit/s

Auxiliary - RS232: 2400 to 115200 bit/s

Ethernet

3

: 10/100 Mbit/s

Inputs

Input 1 (External Trigger) and Input 2 opto-isolated and polarity

insensitive

Maximum voltage: 30 V dc

Maximum input current: 10 mA

Operating Conditions

Operating Temperature

4

: 0 °C to +50 °C (+32 °F to +122 °F)

Liquid Lens Autofocus models Operating Temperature

4

: 0 °C to +45 °C

(+32 °F to +113 °F)

Storage Temperature: –20 °C to +70 °C (–4 °F to +158 °F)

90% maximum relative humidity (non-condensing)

Vibration Resistance EN 60068-2-6

14 mm at 2 to 10 Hz; 1.5 mm at 13 to 55 Hz; 2 a (a), 70 to 500 Hz; 2

hours on each axis

Shock Resistance EN 60068-2-27

30 g; 11 ms; 3 shocks on each axis

Bump Resistance EN 60068-2-29

30 g; 6 ms; 5000 shocks on each axis

Environmental Rating

IEC IP67

5

Outputs

3 NPN/PNP/Push-Pull software selectable, reverse polarity and short

circuit protected outputs available (2 Opto-isolated outputs instead if

on page 33 for specifications)

Maximum Current: 100 mA maximum

Output Saturation Voltage (in PNP or NPN mode): < 3 V at 100 mA

Maximum load device voltage drop (in NPN mode): 30 V

Indicators

Power LED

Ready, Good, Trigger, Com, Status LEDs

Ethernet Network LED

Green Spot LED

Other

Smart Teach Button (configurable via Barcode Manager), Beeper

Optical Features

Image Sensor: CMOS sensor with Global Shutter

Image Format: 1.3 M pixels SXGA (1280×1024) pixels

Frame Rate: 60 frames/sec.

Pitch: ±35°

Tilt: 0° to 360°

LED Safety: LED emission according to EN 62471

Laser Safey (pointers): IEC60825-1 2007

Lighting System: Internal Illuminator

Aiming System: Laser Pointers

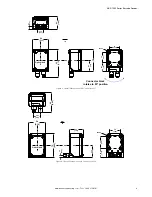

Construction

Aluminum

Weight

About 238 grams (8.4 oz.)

Required Overcurrent Protection

WARNING: Electrical connections must be

made by qualified personnel in accordance

with local and national electrical codes and

regulations.

Overcurrent protection is required to be provided by end product

application per the supplied table.

Overcurrent protection may be provided with external fusing or via

Current Limiting, Class 2 Power Supply.

Supply wiring leads < 24 AWG shall not be spliced.

For additional product support, go to

.

Supply Wiring (AWG)

Required Overcurrent Protection (Amps)

20

5.0

22

3.0

24

2.0

26

1.0

28

0.8

30

0.5

Certifications

FCC Statement

Modifications or changes to this equipment without the expressed written approval of Banner Engineering could void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received, including interference which may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

3

The Ethernet interface supports application protocols: TCP/IP, EtherNet/lP, Modbus TCP

4

High ambient temperature applications should use metal mounting bracket for heat dissipation.

5

IEC IP67 when correctly connected to IP67 cables with seals.

ABR 7000 Series Barcode Reader

www.bannerengineering.com - Tel: + 1 888 373 6767

7