Banner AG4 Series Safety Laser Scanner

Product Manual

P/N 144924 05/2009

39

12.

Mark the PF boundaries on the floor (not required, but recommended).

13.

Under controlled conditions where no personnel are exposed to the hazard, test the Scanner along these boundary markings.

Important:

Verify that the Scanner OSSDs switch off whenever the protective field is entered.

Check to be sure there are no unprotected access routes to the hazard.

See

Commissioning and Check out procedures in Section 7

14.

Measure these protective field boundaries to be sure that the proper separation distance has been established.

15.

Connect the AG4 OSSDs to the machine interface and, under controlled conditions where no personnel are exposed to the hazard, test

the Scanner along and within the boundaries to ensure that the dangerous motion will stop and not start up while an object is in the

protective field.

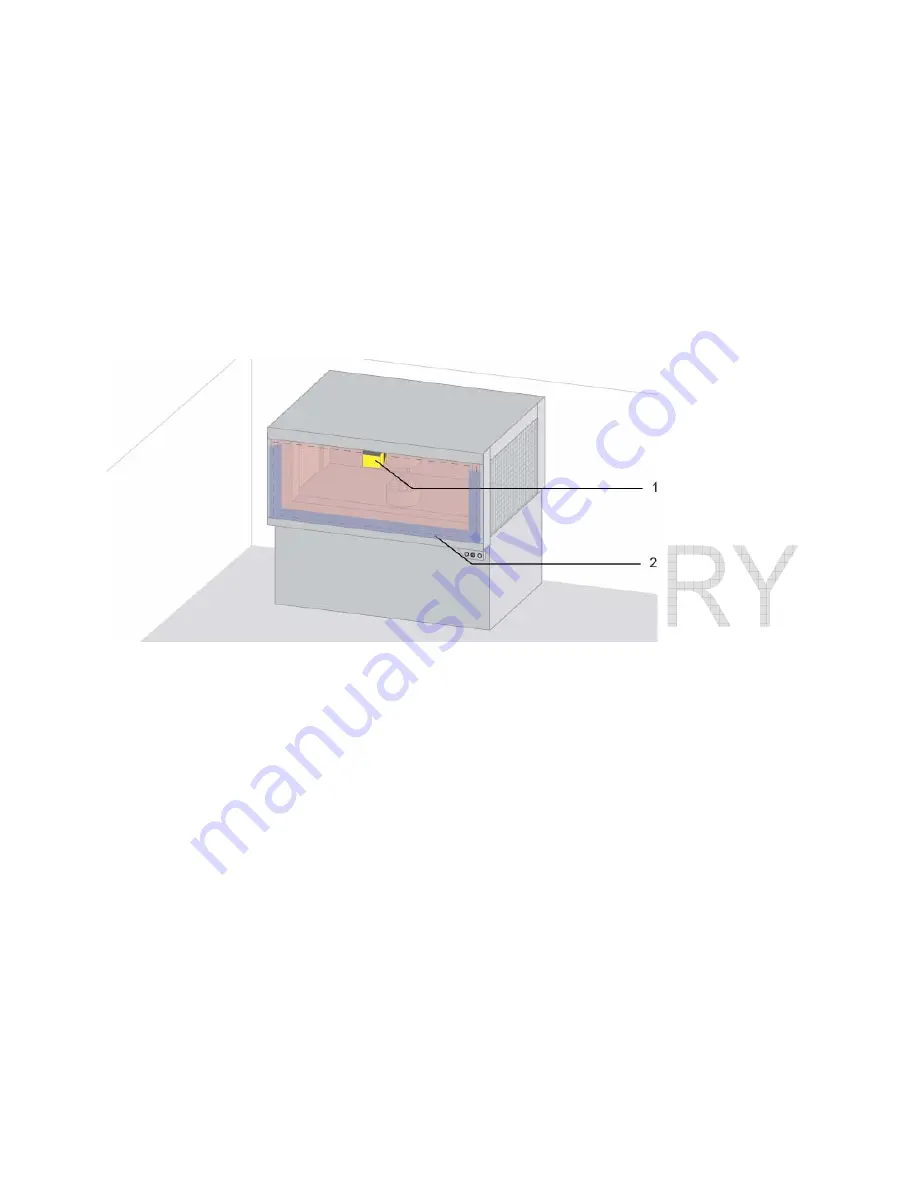

4.6.2

Hazard guarding - approach is normal to the protective field

1 Scanner

2 Reference

contour

Figure 25. Hazard guarding - approach is normal to the protective field

The Scanner controls the machine stopping and presence detection of personnel (restart inhibit) function.

The following is required:

Hand detection: 30 mm

Arm detection: 40 mm

The required finger protection is ensured here by an additional distance “

C

”, which depends on the resolution, in addition to the

minimum separation (safety) distance.

Procedure Basics -

NOTE: For more information on the configuration steps see the AG4soft Software Instruction Manual.

1.

Determine the position of the Scanner on the machine.

2.

Determine all of the response times including the AG4, interface relays, machine stop function.

3.

Consider and account for any factors that could increase the dangerous motion stop time e.g., brake performance degradation.

4.

Consider and account for other factors that may require an increase in the separation (safety) distance such as

Z

SM

or

Z

refl.

5.

Based on the field resolution, calculate the value for

Dpf

or

C

if needed.

6.

With the information above, calculate the minimum separation distance using either US or European standards.

7.

Mount the AG4 on the machine.

8.

Configure the AG4 with the proper start up, restart (reset) and other safety-relevant parameters.