Banner AG4 Series Safety Laser Scanner

Product Manual

P/N 144924 05/2009

27

4.3

Handling unmonitored areas

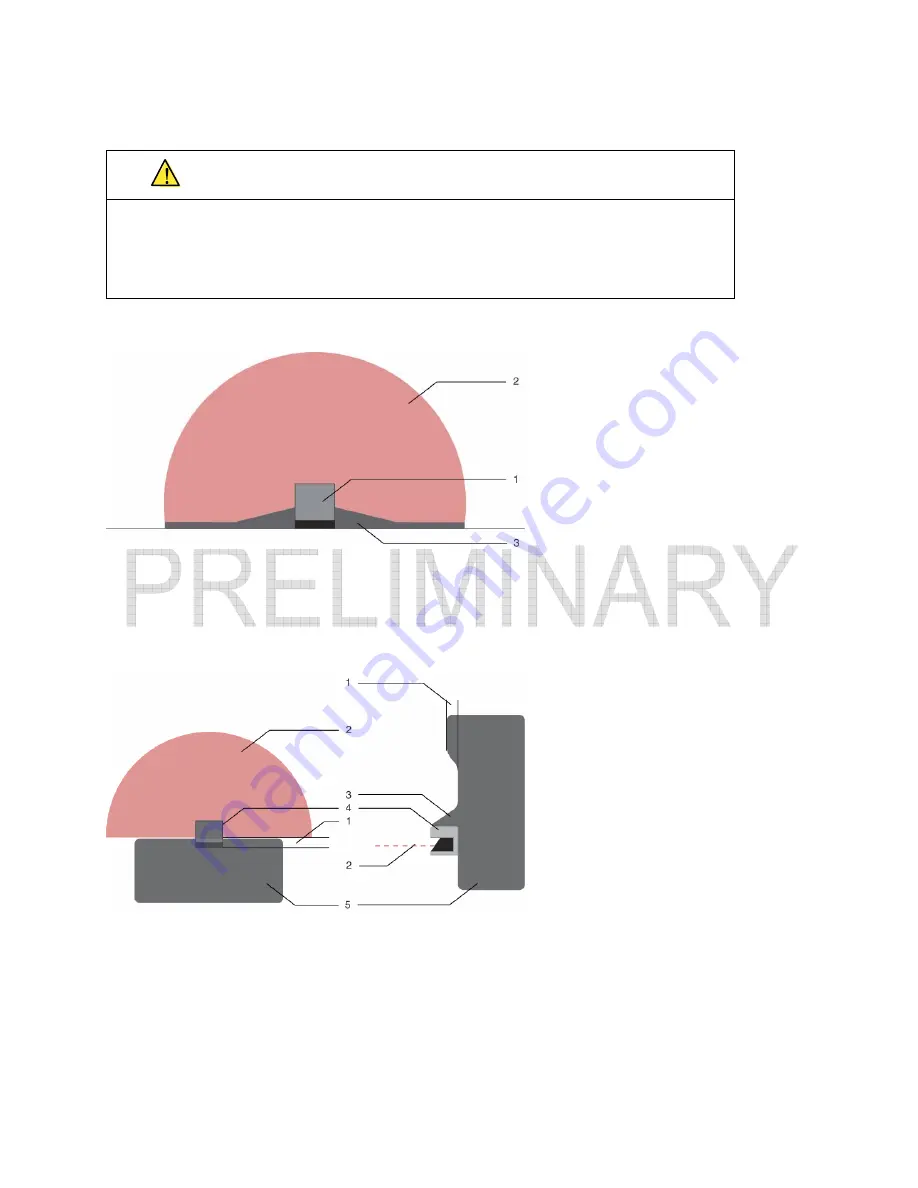

WARNING . . . UNMONITORED AREAS

The area behind and on either side, near the Scanner (in the figure below) is not monitored. It can create an access route to

the hazard point or a

blind zone where a person cannot be detected

. Make sure that this unmonitored area is minimized,

by recessing the Scanner into the machine or protecting it with supplemental guarding devices, so that no one can access this

area undetected.

Failure to do so could result in serious bodily injury or death.

The area behind the AG4 is not monitored. It must not be possible to walk in unmonitored areas.

1 Scanner

2 PF

3 Unmonitored

area

Figure 13. Protective field – Unmonitored Areas

Prevent access to an unmonitored area with screens.

Prevent walking behind by recessing the Scanner into the machine surface.

1 Recessing into the machine surface

2 PF

3 Physical cover

4 Scanner

5 Machine

Figure 14. Rear Area Protection by Recessing into the Machine Contour

If there is a possibility that the Scanner could be used as a climbing aid or standing surface, use a protective cover set at an angle over the

Scanner.