Banner AG4 Series Safety Laser Scanner

3.5 Electrical Connections

Lockout/tagout procedures may be required (refer to OSHA 29CFR1910.147, ANSI Z244-1, or the appropriate standard

for controlling hazardous energy). Following relevant electrical standards and wiring codes, such as the NEC, NFPA79

or IEC60204-1, always connect earth ground (green/yellow wire, see Figures 3-18, 3-19 and 3-20).

Do not operate the

Scanner without an earth ground connection. See the warning above.

Make the electrical connections in the order described in this section.

Do not remove cover; no internal

connections are to be made. All connections are made via the X1 and X2 connectors. When the X2 connection is no

longer required, ensure that the X2 Dust Plug (

AG4-PCD9

) is re-installed to maintain the IP65 environmental rating.

3.5.1 Routing Cables

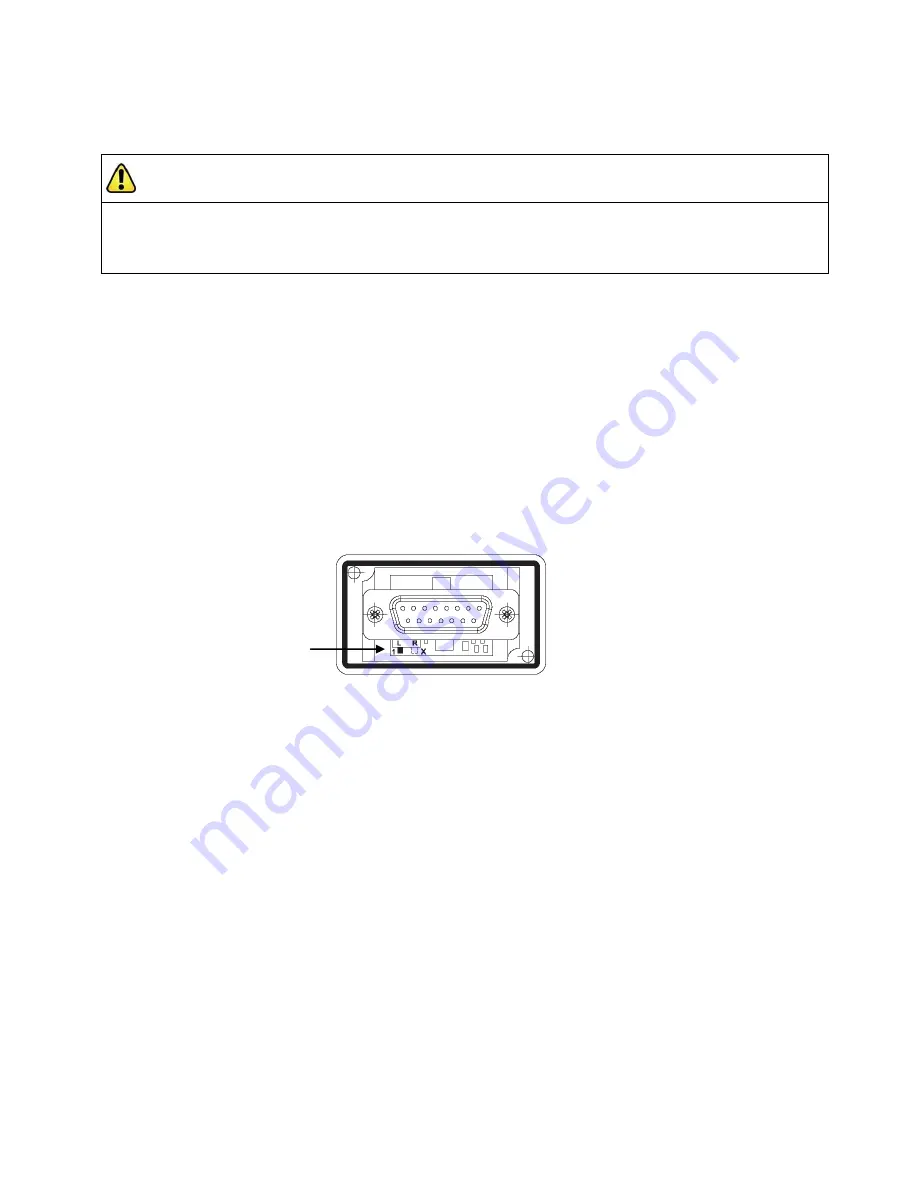

Before connecting the Machine Interface X1 cordset to the Scanner, ensure that the slide switch in the plug housing is

set to the "1" (left) default position (see Figure 3-15).

The X1 cordset has an integrated memory in which the configuration will be stored and automatically re-configure the

Scanner at power-up. The Scanner signals the successful transfer by briefly flashing yellow LEDs 2 and 5.

Figure 3-15. Machine Interface X1 cordset memory settings

Attach the required cordsets to the Scanner (Machine Interface X1 and PC Interface X2), and route the Machine

Interface cable to the junction box, electrical panel, or other enclosure in which the safety module, the redundant

mechanically linked interposing relays, FSDs/MPCEs, or other safety-related parts of the control system are located.

This must be done per local wiring code for low-voltage dc control cables and may require installation of electrical

conduit. See Sections 2.1.1 and 2.4 for information about Banner-supplied cables.

Do the same with the PC interface cable if it is to be permanently installed; if this connection is only to be used during

configuration (or troubleshooting), route the cable to the PC such that it does not interrupt the scanning field. Once

configuration is complete, remove the PC Interface cable and replace it with the supplied X2 Dust Plug (

AG4-PCD9

) to

maintain the IP rating.

The Scanner is designed and manufactured to be highly resistant to electrical noise and to operate reliably in industrial

settings. However, extreme electrical noise may cause a random Trip or Latch condition; in extreme cases, a Lockout is

possible. Scanner wiring is low voltage;

routing the cables alongside power wires, motor/servo wires, or other

high voltage wiring may inject noise into the Scanner.

It is good wiring practice (and may be required by code) to isolate Scanner cables from high-voltage wires, avoid routing

cables close to ―noisy

‖ w

iring, and provide a good earth ground connection to the cordset shield.

WARNING . . . PROPER ELECTRICAL HOOKUP

Electrical hookup must be made by Qualified Personnel and must comply with NEC (National Electrical Code) and local standards.

Make no more connections to the Scanner than are described in Sections 3.5 through 3.8 of this manual.

Connection of other wiring or equipment

to the Scanner could result in serious bodily injury or death.

―X

‖

position: Memory reads

configuration from AG4

"1" (default) position: Memory

sends configuration to AG4

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com