WARNING:

• Not a Safety Category 4 Application

• Failure to verify the proper operation of each switch could result in serious injury or death.

• When monitoring multiple guards with a series connection of multiple safety interlock switches, a

single failure may be masked or may not be detected. When such a configuration is used,

regularly verify the proper operation of each switch.

Series-connected, positive-opening interlock switch circuits do not meet ISO 13849-1 Safety Category 4 and may not meet

Control Reliability requirements because of the potential of an inappropriate reset or a potential loss of the safety stop

signal. A multiple connection of this type should not be used in applications where loss of the safety stop signal or an

inappropriate reset could lead to serious injury or death. The following two scenarios assume two positive-opening safety

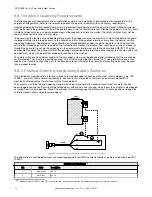

switches on each guard:

Masking of a failure. If a guard is opened but a switch fails to open, the redundant safety switch will open and cause the EZ-

SCREEN to de-energize its outputs. If the faulty guard is then closed, both Cascade input channels also close, but because

one channel did not open, the EZ-SCREEN will not reset.

However, if the faulty switch is not replaced and a second “good” guard is cycled (opening and then closing both of the

cascade input channels), the EZ-SCREEN considers the failure to be corrected. With the input requirements apparently

satisfied, the EZ-SCREEN allows a reset. This system is no longer redundant and, if the second switch fails, may result in an

unsafe condition (i.e., the accumulation of faults results in the loss of the safety function).

Non-detection of a failure. If a good guard is opened, the EZ-SCREEN de-energizes its outputs (a normal response). But if a

faulty guard is then opened and closed before the good guard is re-closed, the failure on the faulty guard is not detected.

This system also is no longer redundant and may result in a loss of safety if the second safety switch fails to switch when

needed.

The circuits in either scenario do not inherently comply with the safety standard requirements of detecting single faults and

preventing the next cycle. In multiple-guard systems using series-connected positive-opening safety switches, it is

important to periodically check the functional integrity of each interlocked guard individually.

Operators, maintenance personnel, and others associated with the operation of the machine must be trained to recognize

such failures and be instructed to correct them immediately.

Open and close each guard separately while verifying that the EZ-SCREEN outputs operate correctly throughout the check

procedure. Follow each gate closure with a manual reset, if needed. If a contact set fails, the EZ-SCREEN will not enable its

reset function. If the EZ-SCREEN does not reset, a switch may have failed; that switch must be immediately replaced.

This check must be performed and all faults must be cleared, at a minimum, during periodic checkouts. If the application

can not exclude these types of failures and such a failure could result in serious injury or death, then the safety switches

must not be connected in series.

EZ-SCREEN

®

14/30 mm Safety Light Screen

76

www.bannerengineering.com - Tel: + 1 888 373 6767