3 Introduction

3.1 Features

• An optoelectronic safeguarding device

• Creates a screen of synchronized, modulated infrared sensing beams;

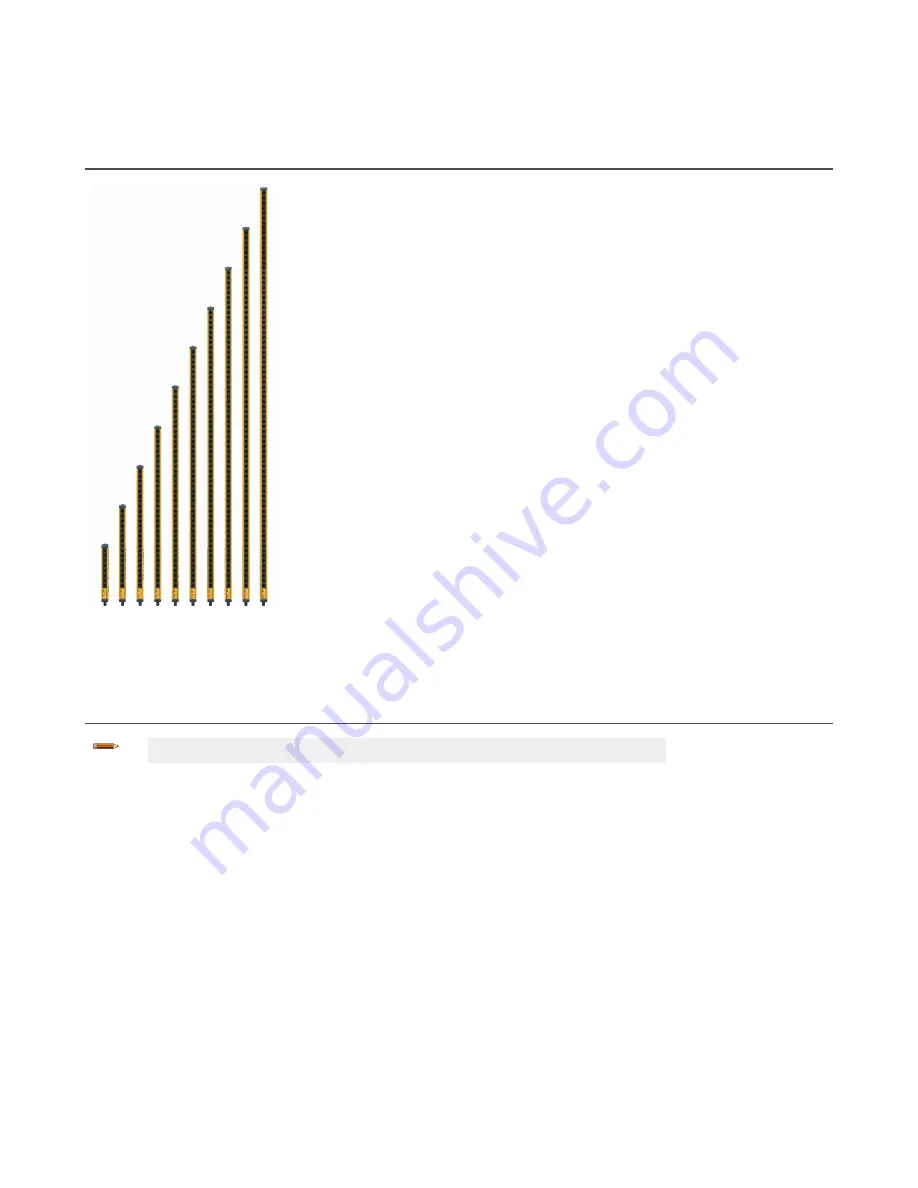

choose from two resolutions, sized in 150 mm (6 in) increments:

◦

14 mm (0.55 in) resolution models with defined areas from 150 mm

to 1.8 m (6 in to 71 in)

◦

30 mm (1.18 in) resolution models with defined areas from 150 mm

to 2.4 m (6 in to 94.5 in)

• Compact package for smaller production machines robust for large power

presses

• Standard or cascadeable models available

• Optional remote Test input terminals for simulating a “blocked” condition

(available on some emitter models)

• Reduced Resolution (Floating Blanking) is easily configured

• Three-digit display provides diagnostic information and indicates the

number of beams blocked

• Zone indicators identify blocked beams

• FMEA tested to ensure control reliability

• Receiver LEDs provide system status and emitter/receiver alignment

indications

• Highly immune to EMI, RFI, ambient light, weld flash, and strobe light

• Two-piece design with External Device Monitoring

• Aux. output option to monitor the state of the OSSDs

• Vibration-tolerant, factory burned-in emitter and receiver circuitry for

toughness and dependability

• Up to four pairs of emitters and receivers of different lengths can be

cascaded (SLSC.. models)

• Safety PLC input compatible (per OSSD specifications)

3.2 System Description

Note: This manual refers to an emitter, its receiver, and their cabling as "a System".

Banner EZ-SCREEN emitters and receivers provide a redundant, microprocessor-controlled, opposed-mode optoelectronic

"curtain of light", or "safety light screen". EZ-SCREEN typically is used for point-of-operation safeguarding, and is suited to

safeguard a variety of machinery.

The EZ-SCREEN is a two-piece (two-box) system comprising an emitter and a receiver, but no external controller. The

external device monitoring (EDM) function ensures the fault detection capability required by EN ISO 13849-1 Categories 3

and 4 without a third box, a controller or a "smart" (self-checking) safety module required of systems without EDM.

The EZ-SCREEN emitters have a row of synchronized modulated infrared (invisible) light-emitting diodes (LEDs) in a

compact metal housing. Receivers have a corresponding row of synchronized photodetectors. The light screen created by

the emitter and receiver is called the defined area; its width and height are determined by the length of the sensor pair and

the distance between them. The maximum range is dependent on the resolution; range decreases if corner mirrors are

used. Emitter and receiver pairs with 14 mm (0.55 in) resolution have a maximum range of 6 m (20 ft), and pairs with 30 mm

(1.18 in) resolution have a maximum range of 18 m (60 ft).

In typical operation, if any part of an operator’s body (or any opaque object) of more than a pre-determined cross section is

detected, the solid-state Output Signal Switching Device (OSSD) safety outputs turn OFF. These safety outputs are

connected to the guarded machine’s Final Switching Devices (FSDs) that control the machine primary control elements

(MPCEs), which immediately stop the motion of the guarded machine.

An auxiliary (aux.) output may be used to signal the state of the OSSDs to a process controller (see

EZ-SCREEN

®

14/30 mm Safety Light Screen

8

www.bannerengineering.com - Tel: + 1 888 373 6767