•

Ensure proper System function whenever any maintenance or modification is performed on the System or on the

machinery that is guarded by the System.

6.3.1 Configuring the System for Initial Checkout

For the initial checkout, the EZ-SCREEN LS Basic System must be checked without power available to the guarded

machine. Final interface connections to the guarded machine cannot take place until the light screen system has been

checked out. This may require lockout/tagout procedures (refer to OSHA1910.147, ANSI Z244-1, ISO 14118, or the

appropriate standard for controlling hazardous energy). The OSSD connections will be made after the initial checkout

procedure has been successfully completed.

Verify that:

•

Power has been removed from (or is not available to) the guarded machine and its controls or actuators

•

The machine control circuit or the Safety/Interface Module is not connected to the OSSD outputs at this time

(permanent connections will be made later)

•

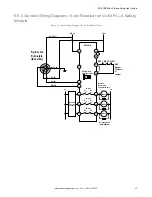

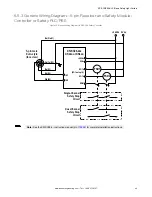

EDM is configured and wired per application requirements (1-channel or no monitoring, see

on page 44)

6.3.2 Initial Power-Up

1. Inspect the area near the light screen for reflective surfaces, including work pieces and the guarded machine.

Reflective surfaces may cause light beams to reflect around a person in the light screen, preventing the person from

being detected and not stopping the machine motion (see

on page 26).

2. Eliminate the reflective surfaces as much as possible by relocating, painting, masking, or roughening them.

Remaining problem reflections will become apparent during the trip test.

3.

Verify that power is removed

from the EZ-SCREEN LS Basic Safety Light Curtain System and from the guarded

machine and that the OSSD safety outputs are not connected.

4. Remove all obstructions from the light screen.

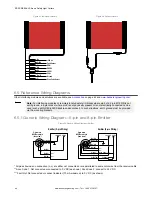

5. With the power to the guarded machine Off, make external device monitoring (EDM), power, and earth ground

connections on both the emitter and receiver cables (see

on page 46). The +24 V dc

(brown wire) and 0 V dc (blue wire) should be connected to a SELV-rated supply and GND (green/yellow wire) to

earth ground. If the installation does not allow direct connection to earth ground via the cordset, the earth ground

must be provided via the mounting brackets.

6. Power up the EZ-SCREEN LS Basic Safety Light Curtain System only.

7. Verify that the input power is present to both the emitter and the receiver. At least one indicator on both the emitter

and the receiver should be On and the start-up sequence should cycle.

8. Watch both the emitter and the receiver Status indicators and the receiver Alignment indicators to determine the light

screen alignment status:

•

An Emitter Lockout Condition

—the emitter Status indicator is single-flashing red; the receiver Status

indicator is solid red, and the receiver's 7-segment display reads

CH1

.

•

A Receiver Lockout Condition

—the receiver Status indicator is single-flashing red, with Alignment and Run

mode indicators Off, and the receiver 7-segment display shows an Error Code.

•

Normal Operating Mode (emitter)

—the Status indicator is solid green.

•

Clear (Run) Condition (receiver)

—the Status indicator is solid green, and the Run mode indicator is solid

amber. All Alignment indicators are solid green.

•

A Blocked Condition (receiver)

—The Status indicator is solid red, Run mode indicator is solid amber, one

or more Alignment indicator(s) are solid red, identifying the location of the blocked beams, and the number of

blocked beams is displayed.

Note:

If beam 1 is blocked, the Alignment indicator 1 will be red and all others Off. Beam 1

provides the synchronization signal.

9. Proceed to

6.3.3 Optical Alignment

WARNING:

•

Hazard exposure

•

Failure to follow these instructions could result in serious injury or death.

•

Verify that no individuals are exposed to any hazard if the output signal switching device (OSSD)

outputs turn on when the emitter and receiver become aligned.

Verify the optimal alignment, adjusting the sensor rotation with the power on:

EZ-SCREEN

®

LS Basic Safety Light Curtain

38

www.bannerengineering.com - Tel: + 1 888 373 6767