c) Supplemental safeguarding and hard (fixed) guarding, as described by the appropriate safety standards, are in

place and functioning properly in any space (between the defined area and any hazard) which is large enough to

allow a person to stand undetected by the EZ-SCREEN LS Basic.

5. If used, verify that all reset switches are mounted outside and in full view of the guarded area, out of reach of anyone

inside the guarded area, and that means of preventing inadvertent use is in place.

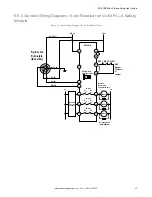

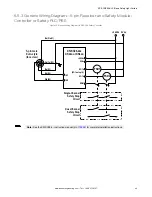

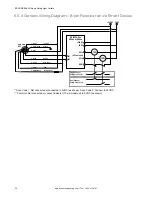

6. Examine the electrical wiring connections between the EZ-SCREEN LS Basic OSSD outputs and the guarded

machine’s control elements to verify that the wiring meets the requirements stated in

on page 41.

7. Inspect the area near the defined area (including work pieces and the guarded machine) for reflective surfaces (see

on page 26). Remove the reflective surfaces if possible by relocating them, painting,

masking or roughening them. Remaining problem reflections will become apparent during the Trip Test.

8. Verify that power to the guarded machine is Off. Remove all obstructions from the defined area. Apply power to the

EZ-SCREEN LS Basic System.

9. Observe the Status indicators and Diagnostic Display:

•

Lockout:

Status flashing red; all others Off

•

Blocked:

Status—Solid red; one or more Alignment indicators— Solid red; Run Mode— Solid amber

•

Clear:

Status—Solid green; Alignment indicators— Solid green (flashing green indicates blanking is enabled);

Run Mode— Solid amber

10. A Blocked condition indicates that one or more of the beams is misaligned or interrupted. To correct this situation,

see

on page 38.

11. After the green and amber Status indicators are On,

perform the trip test

on page 40) on each

sensing field to verify proper System operation and to detect possible optical short circuits or reflection problems.

Do

not continue until the EZ-SCREEN LS Basic passes the trip test.

Important: Do not expose any individual to any hazard during the following checks.

WARNING:

•

Clear the guarded area before applying power or resetting the system

•

Failure to clear the guarded area before applying power could result in serious injury or

death.

•

Verify that the guarded area is clear of personnel and any unwanted materials before

applying power to the guarded machine or before resetting the system.

12. Apply power to the guarded machine and verify that the machine does not start up.

13. Interrupt (block) the defined area with the supplied test piece and verify that it is not possible for the guarded machine

to be put into motion while the beam(s) is blocked.

14. Initiate machine motion of the guarded machine and, while it is moving, use the supplied test piece to block the

defined area. Do not attempt to insert the test piece into the dangerous parts of the machine. Upon blocking any

beam, the dangerous parts of the machine must come to a stop with no apparent delay.

15. Remove the test piece from the beam; verify that the machine does not automatically restart, and that the initiation

devices must be engaged to restart the machine.

16. Remove electrical power to the EZ-SCREEN LS Basic. Both OSSD outputs should immediately turn Off, and the

machine must not be capable of starting until power is re-applied to the EZ-SCREEN LS Basic.

17. Test the machine stopping response time, using an instrument designed for that purpose, to verify that it is the same

or less than the overall system response time specified by the machine manufacturer.

Do not continue operation

until the entire checkout procedure is complete and all problems are corrected.

EZ-SCREEN

®

LS Basic Safety Light Curtain

www.bannerengineering.com - Tel: + 1 888 373 6767

57