3 Product Overview

EZ-SCREEN LS Basic Safety Light Curtain

Banner EZ-SCREEN LS Basic is a two-piece (emitter and receiver), redundant, microprocessor-controlled, opposed-mode

optoelectronic "light curtain" or "safety light screen". Models are available in 23 mm resolution.

Emitters have a row of synchronized modulated infrared (invisible) light-emitting diodes (LEDs) in a robust, compact metal

housing. Receivers have a corresponding row of synchronized photodetectors. The sensing field created by the emitter and

receiver is called the "defined area"; its width and height are determined by the length of the sensor pair and the distance

between them. The sensing range spans from 100 mm to 8 m (4 in to 26 ft), which decreases if corner mirrors or lens shields

are used.

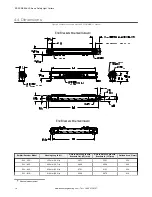

The length of the sensor pair (housing) is dependent on the model, with lengths available from 350 mm to 1820 mm (13.8 in

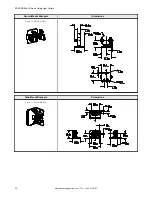

to 71.6 in). The end to end sensing design of the EZ-SCREEN LS Basic, also known as "no blind zone" and "no dead zone,"

allows mounting with minimal or no gaps in detection when using EZLSA-MBK-12 center-mount or EZLSA-MBK-16 side-

mount brackets.

The EZ-SCREEN LS Basic models have trip output (auto power-up and automatic reset). In typical operation, if any part of

an operator's body (or any opaque object) of more than a pre-determined cross section is detected, the solid-state output

signal switching device (OSSD) safety outputs turn Off. These safety outputs are connected to the guarded machine's final

switching devices (FSDs) that control the machine primary control elements (MPCEs), which immediately stop the motion of

the guarded machine. When the defined area becomes clear, the OSSD outputs are allowed to turn ON.

EZ-SCREEN LS Basic sensors are extensively FMEA (Failure Mode and Effects Analysis) tested to establish an extremely

high degree of confidence that when properly installed, no system component (even if it should ever fail) can cause a failure

to danger. Because of the dual scan technology, EZ-SCREEN LS Basic sensors are also highly immune to EMI, RFI,

ambient light, weld flash, and strobe light.

Eight-conductor EZ-SCREEN LS Basic systems (receivers with 8-pin pigtail QD or flying leads) do not require an external

controller when using the external device monitoring (EDM) function. This function ensures the fault detection capability

required by U.S. Control Reliability and ISO 13849-1 Categories 3 or 4 and PL d or e for controlling final switching devices

(FSDs) or Machine Primary Control Elements (MPCEs).

When configured with a five-conductor hookup, the EZ-SCREEN LS Basic requires a self-checking safety module, safety

controller, or safety PLC/PES that conforms to the level of performance required by the risk assessment. Examples include

the UM-FA-9A/-11A safety module, SC10-2roe or XS/SC26-2 safety controller for applications requiring Control Reliability

and/or ISO 13849-1 Categories 3 or 4 and PL d or e.

Electrical connections (power, ground, inputs and outputs) are made via unique RD (removable disconnect) cordsets. A

"System" as referred to in this manual, is defined as an emitter and its receiver, plus their cabling.

Available features include selectable scan code via hookup, an auxiliary fault output, a recessed exit window, and robust

metal housing and end-caps for industry leading durability.

Both emitter and receiver feature 7-segment Diagnostic Displays and individual LEDs to provide continuous indication of

operating status, configuration and error conditions. An adhesive Diagnostics label is provided that includes a summary of

the operational and error codes. Active Alignment (Segment) Indicators provide beam block information and easier

on page 53 for more information.

EZ-SCREEN

®

LS Basic Safety Light Curtain

8

www.bannerengineering.com - Tel: + 1 888 373 6767