50

3. Front axle

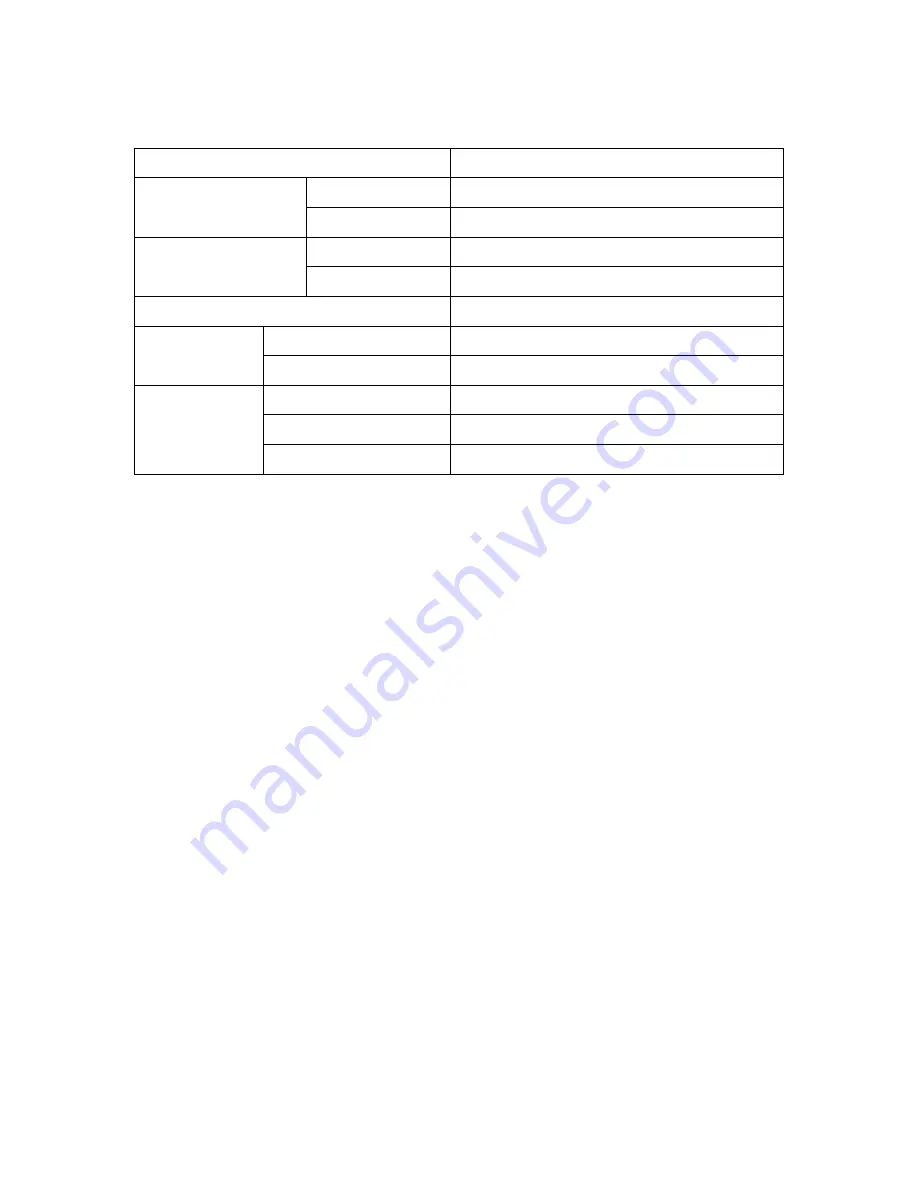

The main specifications of the front axle:

Type

Full-floating type, integral shaped

Main reduction gear

Type

Spiral bevel pinion type

Reduction ratio

6.33

Final reduction gear

Type

Planetary gear type

Reduction ratio

3.58

Total reduction ratio

22.66

Amount of oil

Main reduction gear

Differential

10 L

Final reduction gear

8 L (left and right)

Driving wheel

Tire

9.00-20-14PR

Rim

7.00-20

Air

pressure

KPa

760

3.1 General description

The front axle consists of the main reduction gear, the differential, the final reduction

gear and brakes. (see Fig. 3.1) The front axle is bolted to the front side of the frame.

The mast is installed on the axle housing.

3.2 Main reduction gear & differential

The main reduction gear & differential consists primarily of a cross case, ring gear

(spiral bevel pinion) and drive pinions, which are all assembled on the main reduction

gear carrier as shown in Fig. 3.2, and is fitted to the axle housing through packing.

3.3 Final reduction gear

The final reduction gear is of the planet gear type consisting of a sun gear, planetary

gears and an internal gear. Two final reduction gears are installed on each end of the

axle housing. The sun gear is splined to the axle shaft and locked with snap ring. The

planetary gears are installed onto the shafts in the planet carrier which is fixed to the

wheel hub. The internal gear is splined to the axle spindle through hub.

The principle of power transmission is as follows (see Fig. 3.3).

When the sun gear turns, the rotation is transmitted to the pinion gears and ring gear.

However, since the ring gear is fixed to the spindle, the pinion gears revolve around the

sun gear while spinning themselves. The pinion gears are installed to the carrier which

is fixed to the wheel hub, therefore, power of the drive shaft causes the wheel to turn.

Summary of Contents for CPCD 100

Page 1: ...Original instructions ...

Page 25: ...19 4 Lubrication system 5 Capacity chart 6 Inspections before starting ...

Page 32: ...26 Lubrication diagram ...

Page 50: ...44 Fig 2 4 Forward shift clutch Fig 2 5 Reverse shift clutch Fig 2 6 Control valve ...

Page 61: ...55 Fig 4 2 Position of brake pedal ...

Page 99: ...93 Fig 9 1 Principle diagram of electric system domestic CPCD80 100CY ...

Page 100: ...94 Fig 9 2 Principle diagram of electric system imported CPCD80 100W ...

Page 104: ...98 Fig9 5 1 Diagram of meter harness domestic CPCD80 100CY ...

Page 105: ...99 Fig9 5 2 Diagram of meter harness imported CPCD80 100W ...

Page 106: ...100 Fig9 5 3 Diagram of main harness domestic CPCD80 100CY ...

Page 107: ...101 Fig9 5 4 Diagram of main harness imported CPCD80 100W ...

Page 109: ...103 NOTE ...

Page 110: ...104 ...

Page 112: ...106 incurring any obligation ...