100

The piston, fastened to the piston rod with spring wire is fitted with oil seals and

wearing on its outer periphery.

At the bottom of the lift cylinder there is a cut-off valve, which operates when the

high-pressure hose bursts for any reason to prevent the load from dropping abruptly.

There are steel-backed bearing and oil seal assembled on cylinder head to support

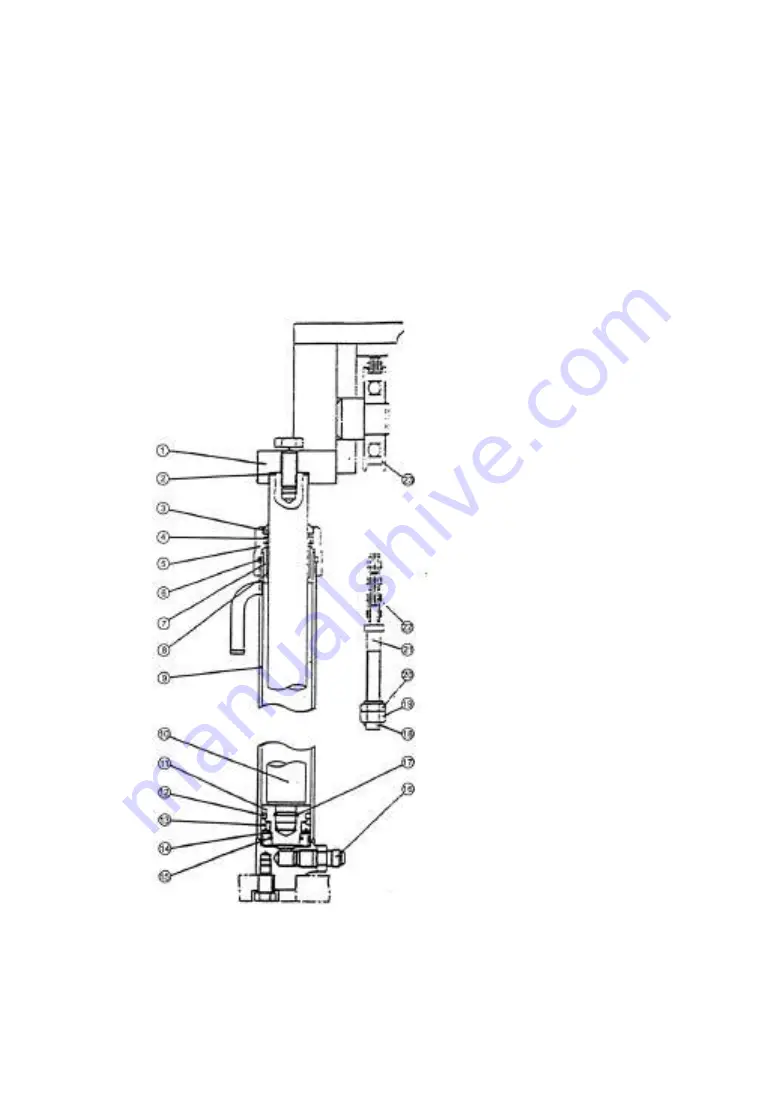

the piston rod and prevent the dust. The diagram of lift cylinder is referred to Fig7-4.

Fig.7-4 Lift cylinder

1. Upper beam

2. Adjust shim

3. Dust ring

4. Oil seal

5. Guide sleeve

6. O-ring seal

7. Cylinder head

8. Steel-backed bearing

9. Cylinder body

10. Piston rod

11. Piston

12. Oil seal, piston

13. Oil seal

14. Ring

15. Snap ring

16. Cut-off valve

17. Spring lock ring

18. Cotter pin

19. Nut, lock

20. Nut, adjustment

21. Joint

22. Chain

23. Chain wheel

Summary of Contents for CPD10

Page 1: ......

Page 6: ...1 Ⅰ External view and specification External view of electric forklift truck ...

Page 26: ...21 2 General information when operating 3 Nameplate of forklift truck 4 Lubrication system ...

Page 27: ...22 5 Capacity chart 6 Inspections before starting 7 Adjust parking brake 8 Add hydraulic oil ...

Page 33: ...28 Fig 1 2 Gear box and differential 2 3t ...

Page 34: ...29 Fig 1 3 Differential ...

Page 57: ...52 Fig 4 2 Principle of electric system DC CPD10 25 ...

Page 58: ...53 Fig 4 3 Principle of electric system DC CPD30 ...

Page 60: ...55 Fig 4 5 Principle of electric system AC ...

Page 77: ...72 4 8 Harness Fig 4 10 Harness DC CPD10 30 ...

Page 78: ...73 Fig 4 11 Harness AC CPD10J 15J ...

Page 79: ...74 Fig 4 12 Harness AC CPD20J 30J ...

Page 81: ...76 Fig 5 1 Assembly diagram of lifting motor Fig5 2 Lifting motor ...

Page 101: ...96 3 Hydraulic oil circuit ...

Page 115: ...110 Fig 8 2 Inner and outer mast 2 3t ...

Page 124: ......