79

5.3.3 Periodic inspection of motor

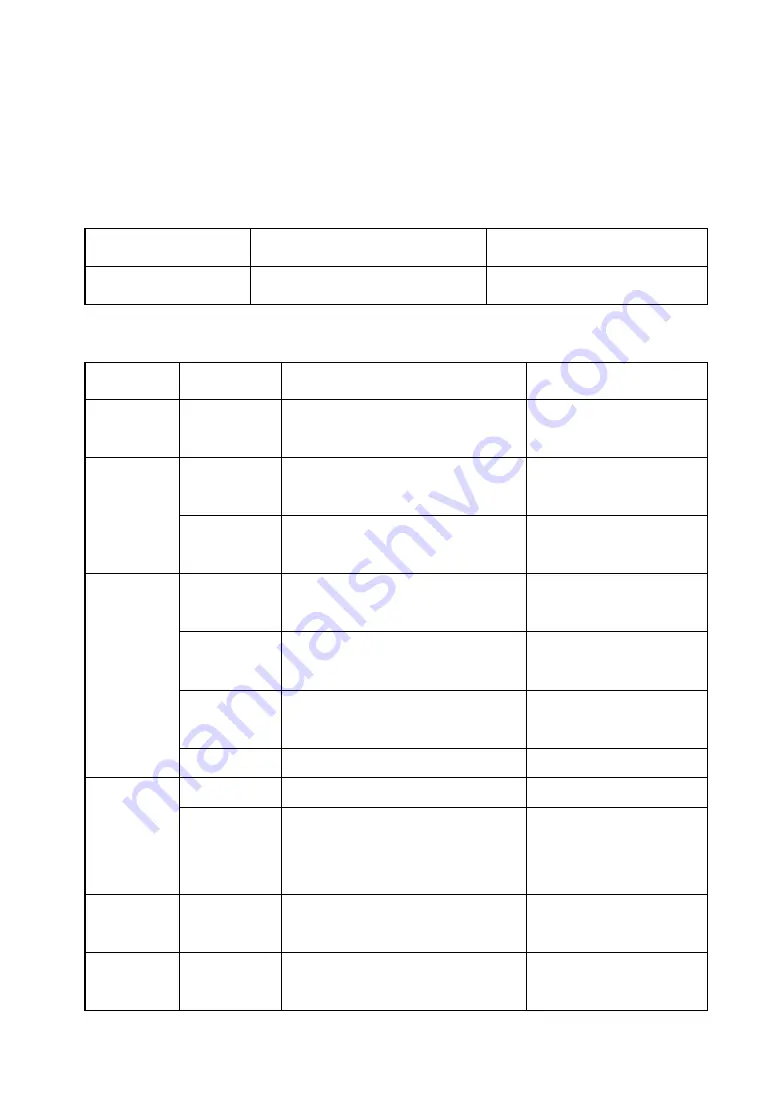

1. Inspecting judgment

Inspection frequency of the motor is related with operation time every day. But at thick

dust or high humidity place, it is necessary to add inspection frequency.

Operation time

More than 12 hours everyday

Less than 12 hours everyday

Check frequency

Once every year

Once every two years

Periodic inspection must be done according to the following list.

Item

Part

Judgment

Remedy

Roller

bearing

Bearing

(sealed)

Visualization, hearing: grease

leakage, noise and dust

Clean, replace.

Connection

part

Surface

Visualization: high roughness

because of damage, rustiness.

Clean, correct.

Screw

Visualization: looseness,

rustiness and dust

Tighten,

antirust, replace.

Terminal

Surface

Visualization: high roughness

because of damage, rustiness

Clean, correct.

Connection

Visualization: connection,

looseness, insulating treatment.

Tighten, replace.

Wire

Visualization: damage of

covering protection.

Professional repair.

Resistance

0.0063Ω±5% (20

℃

)

Professional repair.

Rotor

Core

Visualization: dust

Clean

Coil

Insulating resistance higher than

1MΩ (measured with 500V

ohmmeter).

Clean, heat,

treat with varnish

Damage

Spray paint

Visualization: damage, discolor,

peeling and rustiness.

Antirust

and repaint.

Clean

Foreign

matter, dust

Visualization: dirty, dust, and

rustiness.

Clean, antirust

and paint

Summary of Contents for CPD10

Page 1: ......

Page 6: ...1 Ⅰ External view and specification External view of electric forklift truck ...

Page 26: ...21 2 General information when operating 3 Nameplate of forklift truck 4 Lubrication system ...

Page 27: ...22 5 Capacity chart 6 Inspections before starting 7 Adjust parking brake 8 Add hydraulic oil ...

Page 33: ...28 Fig 1 2 Gear box and differential 2 3t ...

Page 34: ...29 Fig 1 3 Differential ...

Page 57: ...52 Fig 4 2 Principle of electric system DC CPD10 25 ...

Page 58: ...53 Fig 4 3 Principle of electric system DC CPD30 ...

Page 60: ...55 Fig 4 5 Principle of electric system AC ...

Page 77: ...72 4 8 Harness Fig 4 10 Harness DC CPD10 30 ...

Page 78: ...73 Fig 4 11 Harness AC CPD10J 15J ...

Page 79: ...74 Fig 4 12 Harness AC CPD20J 30J ...

Page 81: ...76 Fig 5 1 Assembly diagram of lifting motor Fig5 2 Lifting motor ...

Page 101: ...96 3 Hydraulic oil circuit ...

Page 115: ...110 Fig 8 2 Inner and outer mast 2 3t ...

Page 124: ......