59

5.3 Inspection after reassembling the steering system

(1) Check the force when turning

the steering handwheel to right and left until it can’t

be turned any more to see if they are identical each other and check the operation if the

steering handwheel for smoothness during above operation.

(2) Check the arrangement of the hydraulic pipeline and the turning direction for

correctness.

(3) Lift up the rear wheels and slowly turn the handwheel over several times to

exhaust the air in the hydraulic pipelines and the cylinder.

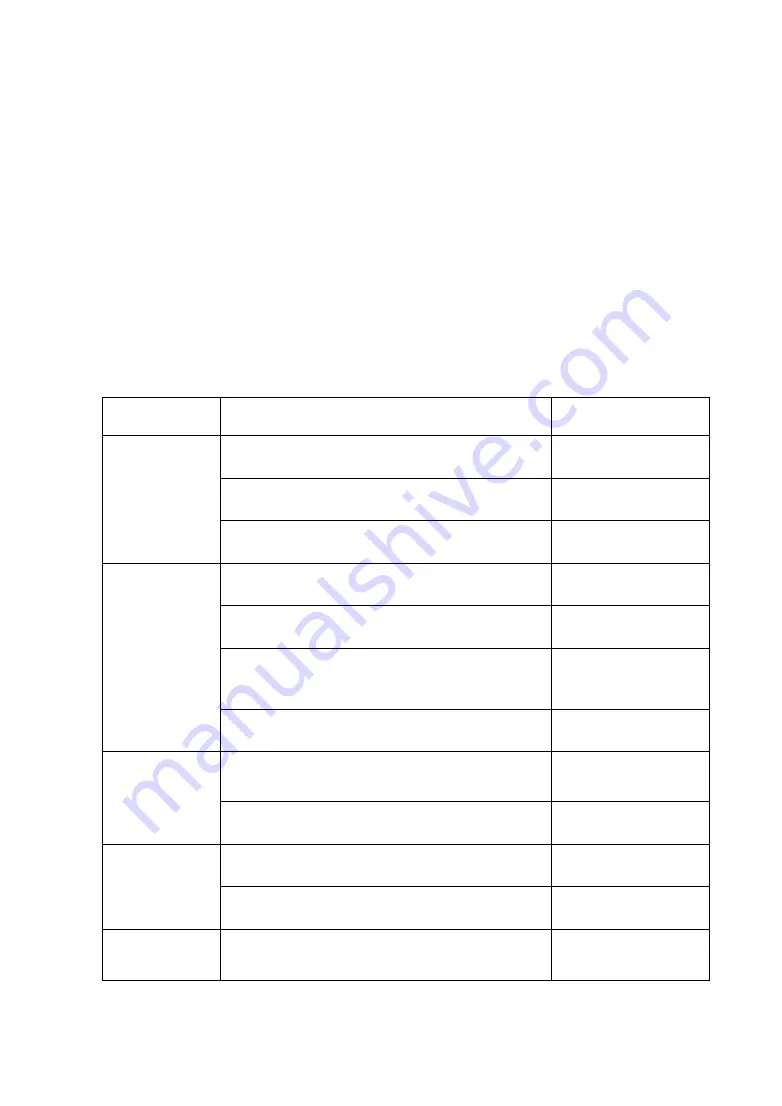

5.4 Troubleshooting of steering system

Problem

Analysis of trouble

Remedy

Fail to turn

handwheel

Oil pump damaged

Replace

Flow-divider blocked or damaged

Clean or replace

Hose or joint damaged or pipeline blocked

Clean or replace

Difficult to

turn

handwheel

Too low oil pressure from flow-divider

Adjust pressure

Air in steering oil circuit

Exhaust air

Steering unit fail to reposition due to spring

piece damaged or insufficient elasticity

Replace spring

piece

Excessive inner-leakage in steering cylinder

Check piston seals

Truck’s naking

or moving with

oscillation

Excessive flow rate for steering

Adjust flow divider

for flow rate

Spring damaged or elasticity insufficient

Replace

Excessive

noise

Too low oil level in oil tank

Refill oil

Suction pipeline or oil filter blocked

Clean or replace

Oil leakage

Seals of guide sleeve, pipeline or joint

damaged

Replace

Summary of Contents for F Series

Page 1: ...1...

Page 7: ...1 About F series forklift truck 1 External view and technical parameter Fig1 1 External view...

Page 95: ...89 Fig8 3 1 Diagram of harness 4JG2 engine...

Page 96: ...90 Fig8 3 2 Diagram of harness Dachai 498 engine...

Page 97: ...91 Fig8 3 3 Diagram of harness Xinchai 498engine...

Page 98: ...92 Fig8 3 4 Diagram of harness Yanmar 4TNE98 engine...

Page 99: ...93 NOTE...

Page 100: ...94...

Page 102: ......