Summary of Contents for ECO 60

Page 2: ......

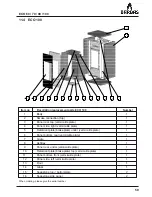

Page 3: ...3 ECO 60 70 90 100 ECO 60 Floor plate is optional ECO 90 ECO 70 ECO 100...

Page 4: ...4 ECO 60 70 90 100...

Page 10: ...10 ECO 60 70 90 100...

Page 72: ...72 ECO 60 70 90 100 12 DIMENSIONS 12 1 ECO 60...

Page 73: ...73 ECO 60 70 90 100 12 2 ECO 70...

Page 74: ...74 ECO 60 70 90 100 12 3 ECO 90...

Page 75: ...75 ECO 60 70 90 100 12 4 ECO 100 SOAPSTONE...

Page 82: ...82 ECO 60 70 90 100...

Page 83: ......