27

Safety, Assembly & Instruction Manual 27

11. TROUBLESHOOTING

Problem

Possible Cause

Prevention/Cure

Burner will not light using knobs or

igniter.

Wires and/or electrode covered

with cooking residue.

Electrode and burners are wet.

Electrode cracked or broken -

sparks at crack.

Wire loose or disconnected.

Clean wire and/or electrode with rubbing

alcohol.

Wipe dry with cloth.

Replace electrode.

Reconnect wire or replace

electrode/wire assembly.

Burner will not light using a match.

No gas flow.

Obstructions of gas flow.

Disengagement of burner to valve.

Spider webs or insect nest venturi.

Burner ports clogged or blocked.

Check if gas cylinder is empty. If empty,

replace or refill.

Clear burner tubes.

Check for bent or kinked hose.

Re-engage burner and valve.

Clean venturi.

Clean burner ports.

Sudden drop in gas flow or reduced

flame height.

Cylinder out of gas.

Check for gas in cylinder.

Irregular flame pattern, flame does

not run the full length of burner.

Burner ports are clogged or

blocked.

Clean burner ports.

Flame is yellow or orange.

New burner may have residual

manufacturing oils.

Spider webs or insect nest in

venturi.

Food residue, grease or seasoning

salt on burner.

Poor alignment of valve to burner

venturi.

Burn grill for 15 minutes with lid open.

Clean venturi.

Clean burner.

Ensure burner venturi is properly engaged

with valve.

Flame blow out.

High or gusting winds.

Turn front of barbeque to face wind.

Low on ULPG gas.

Replace or refill gas cylinder.

Flare-up.

Persistent grease fire.

Grease buildup.

Excessive fat in meat.

Excessive cooking temperature.

Grease trapped by food buildup

around burner system.

Clean grill.

Trim fat from meat before grilling.

Adjust (lower) temperature accordingly.

Turn knobs to “

OFF”

. Turn gas “

OFF”

at

cylinder. Leave lid in closed positions and

let fire burn out. After grill cools, remove

and clean all parts.

Flashback (fire in burner tubes).

Burner and/or burner tubes are

blocked.

Clean burner and/or burner tube(s).

Inside of lid is peeling - like paint

peeling.

The lid is stainless steel, not

painted.

Baked on grease buildup has turned to

carbon and is flaking off. Clean thoroughly.

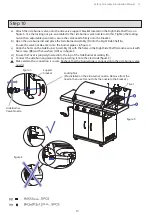

Irregular flame.

Air flow is not correct.

Correct

Flame

blue with yellow tips, 25-

50mm high.

Too little air:

yellow or orange flames.

Too

much air:

noisy blue flames.

If flames are yellow or orange - open flap at

end of the venturi tubes in 2mm increments

until flames are correct.

If flames are blue and noisy - close flap

at the end of the venturi tubes in 2mm

increments until flames are correct.