Manual 2100-458C

Page

8 of 17

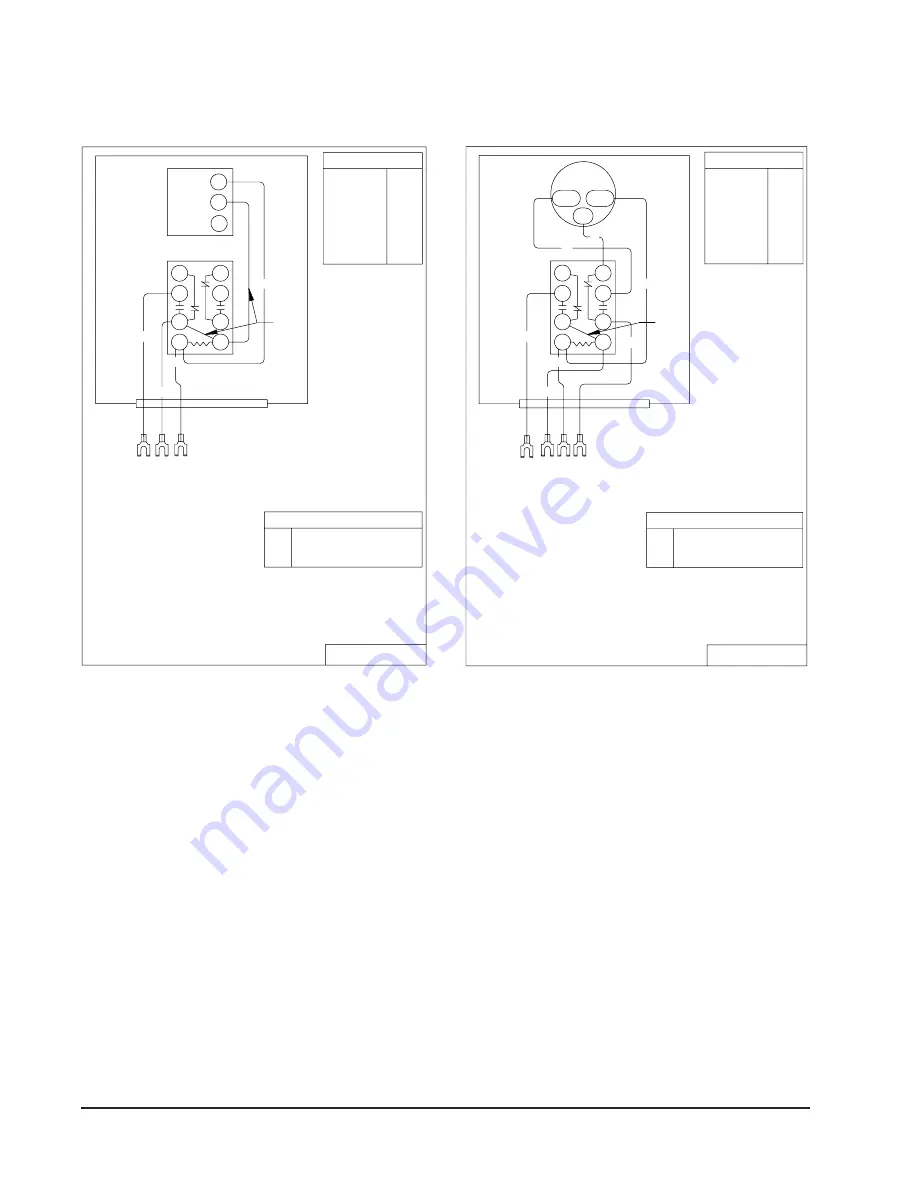

9. Connect leads with fork terminal to corresponding

points on unit terminal strip. (See wiring diagram,

Figure 5A or 5B, or on ventilator.)

10. Close control panel cover.

11. Replace left filter support, filter and four (4) screws

in condenser grille.

12. Reinstall the blower access panel at top of unit and

secure with sheet metal screws.

13. Ventilator Checkout

A. Remove mist eliminator to allow access to

minimum position thumbwheel or blade stops.

B. Resupply power to unit.

C. Energize the evaporator blower by switching

thermostat to the manual fan position with

heat/cool in OFF position.

D. Ventilator should open to the position set by

position adjustment thumbwheel on the CRVS,

or to the blade stops on the CRVP. On the

CRVS, cycle position adjustment thumbwheel

to full open through full close. Observe damper

blade operation throughout travel to assure free,

unobstructed movement. (See Figure 5.)

E. De-energize evaporator blower. Damper blade

should close.

G. This completes ventilator checkout.

14. Adjust damper blade for required ventilation

airflow. (See next section.)

15. Replace mist eliminator. Be sure it is installed with

the drain holes to the bottom.

16. Remove blank off plate or barometric fresh air

damper installed on service access door. Plug four

(4) mounting holes with the plastic plugs provided

with the ventilator.

17. Replace service access panel.

18. Ventilator is now ready for operation.

FIGURE 5

CRVS LEAD CONNECTIONS

CRVP LEAD CONNECTIONS

D

9

BR/W

O

BR/W

T

X

DM

BL

BK

4056-189

CRVS

CR

BK

1

3

4

7

A

B

6

CONTROL RELAY

DAMPER MOTOR

TERMINAL STRIP

CR

DM

TBL

COMPONENT CODE

BLACK

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

WHITE

COLOR CODE

BK

BR

R

O

Y

G

W

BL

BR/W

O

BR/W

R

BK

4056-180 A

CRVP

CR

BL

Y

BK

CW

CCW COM

DM

1

3

4

7

A

B

6

9

CONTROL RELAY

DAMPER MOTOR

TERMINAL STRIP

CR

DM

TBL

COMPONENT CODE

BLACK

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

WHITE

COLOR CODE

BK

BR

R

O

Y

G

W