Manual 2100-422

Page 6

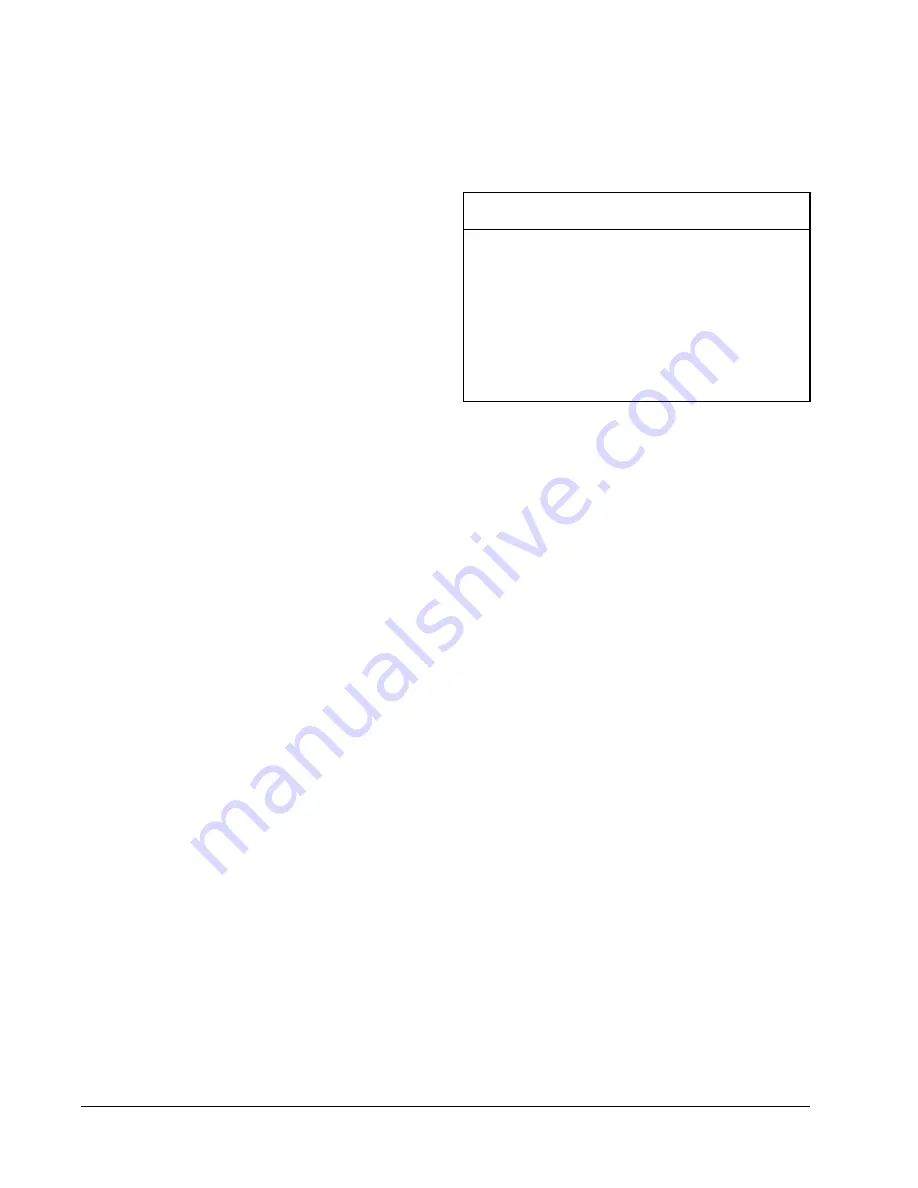

IMPORTANT

When a furnace is installed so that supply

ducts carry air circulated by the furnace to

areas outside the space containing the

furnace, the return air must also be handled

by a duct(s) sealed to the furnace casing and

terminating outside the space containing the

furnace This is to prevent drawing possible

hazardous combustion products into the

circulated air.

INSTALLING THE FURNACE

INSTRUMENTS REQUIRED FOR PROPER

SETUP OF THE FURNACE

It is important that a set of instruments capable of the

following requirements be used for the setup of this

furnace to ensure proper and safe operation:

1. Oil pump pressure gauge that measures up to

150 PSI.

2. Smoke gun to pull smoke samples from flue.

3. Draft gauge that will measure -.02” water column

(W.C.)

4. Duct static pressure gauge 0-1.0” W.C. range.

5. Temperature gauge that can read from 50° F up to

700° F.

6. A gauge to measure CO

2

or O

2

.

INSTALLATION

A typical installation is shown in Figures 4 and 5. All

parts of the furnace installation (furnace, oil tank and

piping systems, combustion and ventilation air, venting,

etc.) must comply with NFPA31, Installation of Oil

Burning Equipment -- latest edition. This drawing

shows the typical connecting parts needed to correctly

install this furnace. Make sure that all parts of the

heating system comply with the local codes.

Check the furnace and your load calculation to verify

that the unit is properly sized. (Refer to Equipment

Selection” section on Page 2.)

The correct size of unit needed may be substantially

smaller than the unit being replaced due to home

improvements and technology advancements since the

initial installation.

INADEQUATE SUPPLY AIR and/or RETURN

AIR DUCT SYSTEMS

Short cycling because of limit control operation can be

created by incorrectly designed or installed supply and/

or return air duct systems.

The duct systems must be designed using ASHRAE or

ACCA design manuals and the equipment CFM and

external static pressure ratings to insure proper air

delivery capabilities.

On replacement installations, particularly if equipment

is oversized, the duct systems can easily be undersized.

Modifications may be required to assure that the

equipment is operating within the approved

temperature rise range when under full rated input

conditions, and that no short cycling on limit controls is

occurring.

DUCT WORK

The air distribution system should be designed and

installed in conformance with manuals published by Air

Conditioning Contractors of America (ACCA) as set

forth in Manual D, or ASHRAE publications.

INSTALLING A COOLING UNIT

When the furnace is used in connection with a cooling

unit*, the furnace shall be installed parallel with or on

the upstream side of the cooling unit to avoid

condensation in the heating element. With a parallel

flow arrangement, the dampers or other means used to

control flow of air shall be adequate to prevent chilled

air from entering the furnace, and if manually operated,

must be equipped with means to prevent operation of

either unit, unless the damper is in the full heat or cool

position.

*

A cooling unit is an air conditioning coil, heat

pump coil or chilled water coil.

When installing a cooling unit above an FH or FL

(below on an FC) series furnace, the coil must be

spaced far enough from the furnace outlet to assure

proper operation of the furnace. Bard supplied coils,

when used with Bard supplied coil cabinets, are

automatically positioned.

For top discharge FH and FL models, when coils are

installed without using Bard coil cabinets or coils of

another brand are used, the coil drain pan should be

located a minimum of two (2) inches above the top of

the furnace cabinet. If a greater clearance is specified

by the coil manufacturer then it would apply.

NOTE: IF DRAIN PAN IS ANYTHING OTHER

THAN A STEEL PAN PARTICULAR

ATTENTION MUST BE GIVEN TO THE

INSTALLATION INSTRUCTIONS FOR

THE COIL TO MAKE SURE IT IS

ACCEPTABLE FOR USE WITH THESE

OIL FURNACES HAVING MAXIMUM

OUTLET AIR TEMPERATURE OF 200° F.

See CFM versus static pressure curves on pages 33-36

for additional information.