Manual 2100-578L

Page

17 of 42

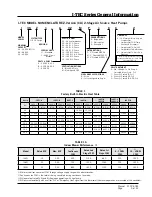

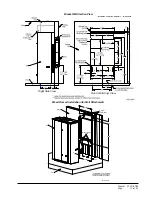

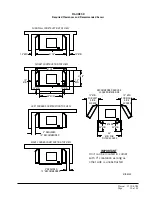

(2) Unit

Drain Entrances

Drain Area

Drains

Insulate

(2) Optional Unit

(2) Drain

Access

Locations

MIS-3115 A

(2) OPTIONAL DRAIN

HOLES IN BASE

WALL

BASE VIEW

16 1/2"

18 3/4"

7 3/16"

40 3/4"

35"

OPTIONAL FLOOR

MOUNTING HOLES

CONDENSATE DRAIN

There are two condensate drain connections from the

condenser drain pan (compressor area). These are

visible from the rear of the unit. Factory-installed

tubing connects the two drains at a tee connection and

then a single drain hose with a barbed hose connector

carries the condensate to the draining option chosen.

Enough tubing is provided to reach all drain options

and can be cut down in length.

The unit is shipped from the factory with the drain

line on the left-hand side when looking at the rear of

the unit. The tubing can be removed from the drain

connections and flipped for a right-hand drain. See

Figure 8.

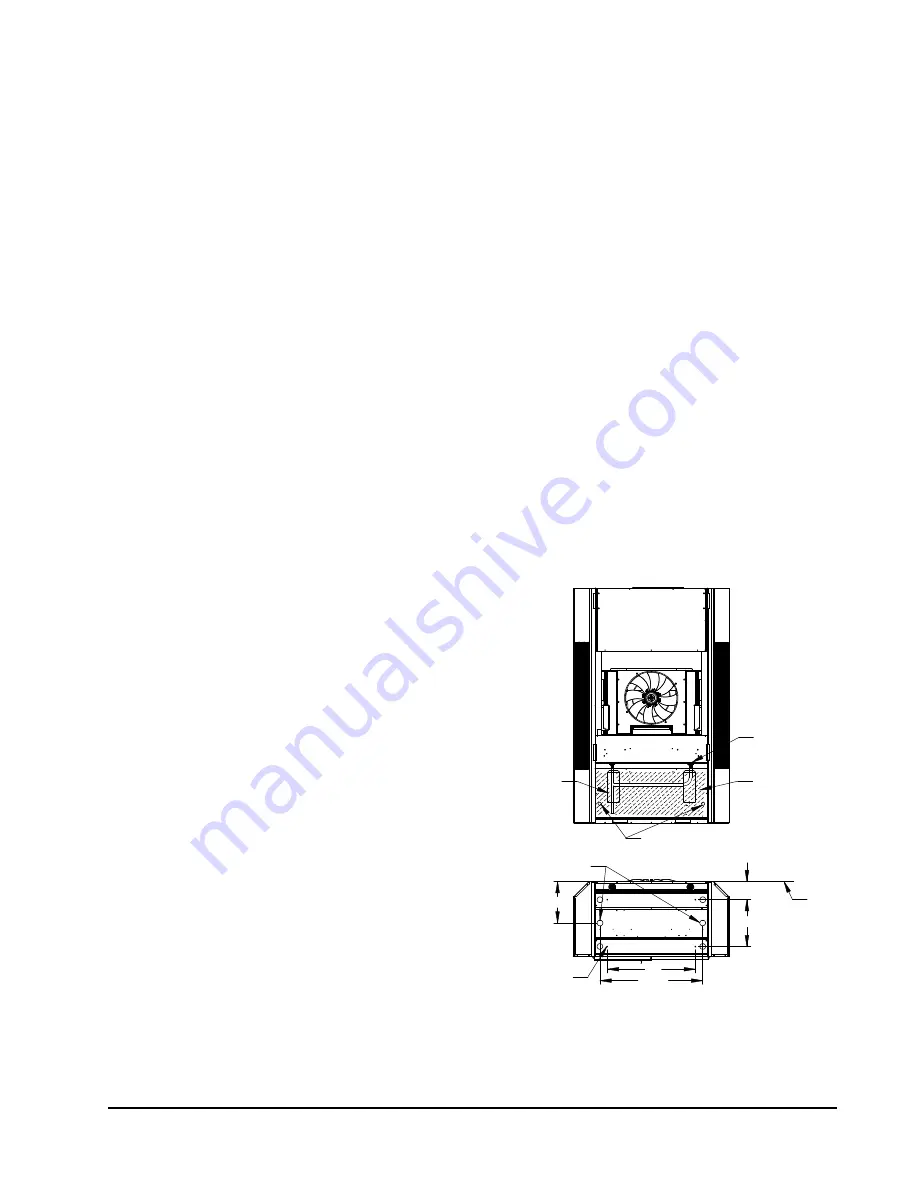

The drain can be routed directly through the floor or

through the wall. There are also two optional drain

locations in the lower rear back panel. See Figure 8.

The I-TEC design does not require a trap in the

condensate disposal tubing. Check local codes to see

if a “P” trap is required.

For a stand pipe floor drain or through the wall, there

is adequate hose length to reach needed location

behind the unit. The lower rear portion of the cabinet is

recessed approximately 4" allowing room for a “P” trap

(if required) to be installed with the cabinet flush with

the wall. Keep in mind, the drain line must be able to

be removed from the unit if necessary to remove the unit

from the wall.

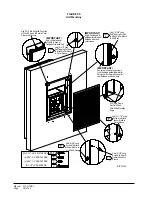

Access plates are located on the rear of the unit for

servicing the drain trap. See Figure 8.

If the drain line

is to be routed through an unconditioned space, it must

be protected from freezing.

The condensate drain line can also be routed back

into the unit through either the right-hand or left-hand

optional drain locations on the rear of the unit. The hole

is covered by insulation on the inside of the unit and

will have to be cut away. Located inside the unit, about

12" in from the front on both the left and right side are

drain holes in the bottom of the base. These holes are

covered with insulation and are not visible from inside

vent option area. They are located very close to the

side panels and can be found by pressing down on the

insulation or looking at back of vent option area (See

Figure 8). Cut insulation away to expose the hole. A

drain trap can now be installed inside of the cabinet,

and the drain hose routed directly through the floor.

Once the I-TEC is installed, the rear drains exiting the

condenser section can be easily serviced with removal

of the pre-painted metal sides (lift-off doors, remove

four [4] screws to remove side).

If side access is not available, the drain lines and trap

can be serviced by removing either one of the drain

access panels on the rear of the unit (in the ventialtion

package area.) See Figure 8.

A

fter drain installation is complete, drain area must

be insulated for sound purposes with 45" x 24¾" x 6"

piece of insulation. See Figure 8.

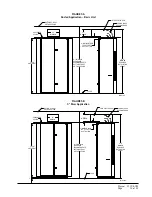

With No Vent Option

To remove the drain access panels in the rear of this

section, simply remove the front door/cover from the

box. Rear drain access panels are now visible on both

right-hand and left-hand sides in rear of box.

With Commercial Room Ventilator

1. Open hinged front doors.

2. Disconnect unit power to eliminate shock hazard.

3. Remove front cover/door of CRV vent package. (Can

leave filter access panels in place.)

4. Unplug wires coming in on left side from upper

unit section.

5. Unplug two wire harness from front (intake) blower.

6. Remove two (2) screws securing front (intake)

blower and slide blower out of unit.

7. Remove four (4) screws that retian the partition

behind/beneath intake blower removed in Step #6.

8. Rear drain access panels are now visible on both

right-hand and left-hand sides in rear of box.

FIGURE 8

Drain Locations