Manual 2100-665A

Page

25 of 51

TEC-EYE

TM

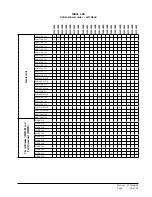

Menu Structure

Quick Menu

Data Log

Unit Information

Setpoints

Main Menu

System Configuration

Advanced System Configuration

I/O Configuration

On/Off

Alarm Logs

Settings

Logout

In addition to the menu structure above, there are also

Status and Alarm screens.

TEC-EYE

TM

Acronyms

MAT – Mixed air temperature

RAT – Return air temperature

OAT – Outdoor air temperature

OAH – Outdoor air humidity

Blower – Indoor Blower Status

Damper – Free cooling damper position status

C1 – Compressor activate status

H1 – Heater Stage 1 status

H2 – Heater Stage 2 status

ODP – Calculated outdoor dew point

FC – Free cooling status

RN – Component run time in minutes in last hour

ST – Number of start requests in last hour

NOTE:

Digital refers to On/Off whereas analog is a

variable input.

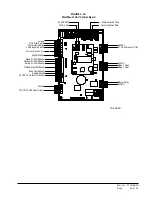

Status Screen

The Status screen is the default start-up screen and

also the return screen after 5 minutes of no activity.

The screen can be accessed any time by pressing the

BACK button repeatedly.

The wall-mount unit address is displayed in the upper

right corner on the Status screen (see Figure 2.1). The

Status screen also shows the current date, time, return

air temperature, mixed air temperature, outdoor air

temperature, outdoor humidity and outdoor dewpoint

conditions. Blower, damper and unit status are also

displayed.

The Quick Menu is accessible from the Status screen.

Data Log, Unit Information and Setpoints are available

through the Quick Menu. Pressing the UP or DOWN

keys while on the Status screen will change the Quick

Menu icon displayed (see Figure 2.3). Press the

ENTER key when the desired icon is displayed.

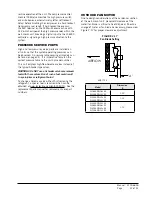

Setpoints: Local Cool and Heat/Current Cool and Heat

If at any time the unit(s) loses communication with

the LC6000 controller, the unit(s) will go to stand

alone mode. Local cooling and heating setpoints only

apply to stand alone mode. The Current cooling and

heating setpoints are the setpoints for the on and off

differential points.

The LC6000 setpoints will determine the Current

cooling and heating setpoints when communicating.

The Local cooling and heating setpoints will determine

the Current cooling and heating setpoints when in

stand alone mode.

To change local cool and heat setpoints:

1. From the Status screen, press UP or DOWN key

until Quick Menu displays Setpoints icon. Press

ENTER key.

2. Press ENTER key to scroll to the selected choice

(see Figure 2.4).

3. Press UP or DOWN key on desired value until value

displays correctly.

4. Press ENTER key to submit value and move to next

parameter.

5. Press BACK key until Main Menu screen is

displayed.

FIGURE 2.3

Quick Menu Icons

Data Log

Unit Information

Setpoints

FIGURE 2.4

Local Cool/Heat and Current Cool/Heat Setpoints

Executing a Run Test

Execute a run test on each unit to verify the equipment

is functioning correctly.

1. Press MENU key to access the Main Menu screen.

2. Press UP or DOWN keys and ENTER key to enter

USER password 2000.